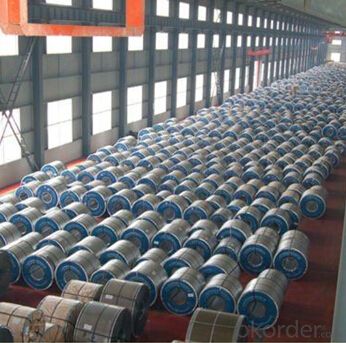

JIS Hot Rolled Steel Coil (1250*3) for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Rolled Steel Coil description:

Model NO.:1250mm*3mm

Surface Treatment:Galvanized

Certification:ISO, SGS

Technique:Hot Rolled

Standard:ASTM, JIS, GB, AISI, DIN, BS

Application:Boiler Plate

Edge:Slit edge

Stock:Stock

Steel Grade:Q235B

1250*3:Mm

Export Markets:Global

Standard: AISI, ASTM, BS, DIN, GB, JIS

Steel Grade: Q235B

Thickness: 1.2mm-20mm

Place of Origin: Changzhou China (Mainland)

Technique: Hot Rolled

Application: Making pipes, etc.

Brand Name: SS400B, Q195, Q235, SPHC, SPHT1

Width: 900mm-2000mm

Length: Coils

Packaging & Delivery

Packaging Detail: Standard package

Delivery Detail: Within 7-15days after we receive your deposit

| Standard | AISI, ASTM, BS, DIN, GB, JIS, |

| Grade | Q195/Q235/Q345/45# |

| Thickness | 2.50,2.70,2.75,2.8,2.9,2.95,3.0,3.25,3.3,3.5,3.75,3.8,3.9,3.95,4,4.25,4.5,4.7,4.75,5,5.5,5.75, 6,6.75,7,7.5,7.75,8,8.75,9,9.5,9.75,10,10.5,11,11.5,12 ,15.75 |

| Width | 685/735/1010/1250/1500/1800/2000mm |

| Coil Weight | 685/735 __6.5 T 1250 __16.5T 1500 __27.5T 1800/2000__32.5T |

| Application | construction, household appliance, Automobile, light industry, etc |

| Packaging | Standard package, suitable for transportation. |

| Delivery | Within 30 days after contract signed |

| Payment term | T/T or L/C |

- Q: What are the safety precautions when working with steel coils?

- When working with steel coils, it is important to follow several safety precautions. Firstly, workers should always wear the appropriate personal protective equipment (PPE) such as safety glasses, gloves, and steel-toed boots to protect themselves from potential hazards. Additionally, it is crucial to ensure that the work area is clean and free from any debris or obstacles that may cause accidents or tripping. Proper manual lifting techniques should be employed to avoid strain or injury when handling heavy steel coils. Workers should also be trained in the proper use of equipment such as cranes or forklifts to safely transport and store the coils. Regular inspections of equipment and proper maintenance should be conducted to prevent any malfunctions or accidents. Lastly, employees should be aware of emergency procedures and have access to fire extinguishers and first aid kits in case of any unexpected incidents. Overall, prioritizing safety measures and being vigilant can greatly minimize the risks associated with working with steel coils.

- Q: How do steel coils contribute to sustainability efforts?

- Steel coils contribute to sustainability efforts in several ways. Firstly, steel coils are made from recycled steel, reducing the need for virgin raw materials and minimizing the environmental impact of mining and processing. Additionally, steel coils are highly durable and long-lasting, meaning that products made using steel coils have a longer lifespan, reducing the frequency of replacements and waste generation. Furthermore, steel is a highly recyclable material, and steel coils can be easily recycled at the end of their life, making them a sustainable choice.

- Q: Are steel pokemon weak against any attacks? If so, what types? (like water, grass, etc.)

- Steel Defensive Strengths: Nearly everything (Only Fire, Ground, and Fighting attacks will put a dent in Steel-types, and Water and Electric do standard damage.) Everything else is wasted effort, especially Poison. (For the whole list, it's Normal, Grass, Ice, Flying, Psychic, Bug, Rock, Ghost, Dragon, Dark, and Steel) Weaknesses: Fire, Fighting, Ground Immune to: Poison Offensive Advantages: Ice, Rock Disadvantages: Water, Fire, Electric, Steel Immunities: None basically fire, fighting and ground

- Q: How are steel coils used in the production of agricultural storage tanks?

- Steel coils are used in the production of agricultural storage tanks as they serve as the primary material for constructing the tank walls and base. The coils are shaped and welded together to form a sturdy and durable structure that can withstand the weight and pressure of storing agricultural products such as grains, feed, and fertilizers. The steel coils provide the necessary strength and corrosion resistance required for long-term storage in various agricultural environments.

- Q: Is sterling silver better than surgical steel as far as being hypoallergic in earrings? If I have a choice which should I get? Thanks!

- Surgical steel.

- Q: Is steel cut really better? The nutritional profiles are nealy identical. Which one has the best flavor??Thanks!

- The biggest difference, is steel cut oats tend to be a European way, and Rolled oats are more North American, Irish and Scottish Oats tend to be steel cut, take longer to cook as the germ and whole grain is almost shredded, where with rolled oats it is process to were only a portion of the bran remains, that is why you can by Oat Bran in North America. We have instant, quick and large flake from Quaker, all cook in a matter of between 2-10 minutes, steel cut can take up to 25-30 minutes and do better in a double boiler, my mother tells a story were her grandmother would prepare it at night and let it sit on the back of the wood stove all night for breakfast the next day.

- Q: I plan to buy a bushcraft knife ..The blade made up by damascus steel.My question is ,is damascus steel is very strong ?

- Pattern welded /damascus is too expensive to use as an everyday knife, as it can cost more than silver. It's best kept as a collection piece. You'd be stupid to keep it in your pocket or use it everyday. that would be a waste of money. Knives you use everyday might be lost or stolen, or they may get rusted, worn, or dirty..... ruining their value. From that point of view the strength or edge-holding ability means very little. Specifically, the bushcraft knife is pattern welded steel. True damascus or Wootz steel is something you'll only find in museums and private collections. they stopped making it several hundred years ago. Despite what many people have claimed, Wootz damascus was inferior to modern tool steels in every respect. It was a brittle, dirty material. It's legendary status has more to do with myth and storytelling. The reason they stopped making was undoubtaby because more modern methods came along that produced a more consistent product, more quickly and easily. Old technologies tend to be abandoned for good reasons. With pattern welded steel, about a dozen strips of two different grades of steel have been stacked, welded together, the twisted and forged to create interesting patterns. This more of an artistic process and doesn't improve the properties of modern steels. Pattern welded steel is for the most part, inferior to a homogenous blade made of a single grade of steel. First of all, PW is a handmade product which means there will be faults and oxide inclusions incorporated into the steel. The welding process is not perfect. Secondly, in the hardening and tempering process you end up with a compromise between the properties of the two different grades of steel. You end up with a product that is not quite as good as either steel would have been individually. The blade may either be too brittle or too soft.

- Q: How are steel coils transported internationally?

- Steel coils are typically transported internationally using various modes of transportation such as ships, rail, and trucks. Ships are commonly used for long-distance transportation, where steel coils are loaded onto specialized vessels equipped with cranes for efficient loading and unloading. Rail and trucks are often used for shorter distances or for transporting steel coils from the port to the final destination. Specialized equipment such as flatbed trailers or intermodal containers are utilized to ensure the safe and secure transport of steel coils.

- Q: How are steel coils used in the manufacturing of automotive doors?

- Steel coils are used in the manufacturing of automotive doors by being processed and shaped into sheets that are then stamped, cut, and formed to create the door's structure. The strength and durability of steel make it an ideal material for automotive doors, ensuring safety and protection for passengers.

- Q: What are the different types of steel coil surface treatments?

- There are several different types of steel coil surface treatments, including hot-dip galvanizing, electro-galvanizing, powder coating, and organic coating.

Send your message to us

JIS Hot Rolled Steel Coil (1250*3) for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords