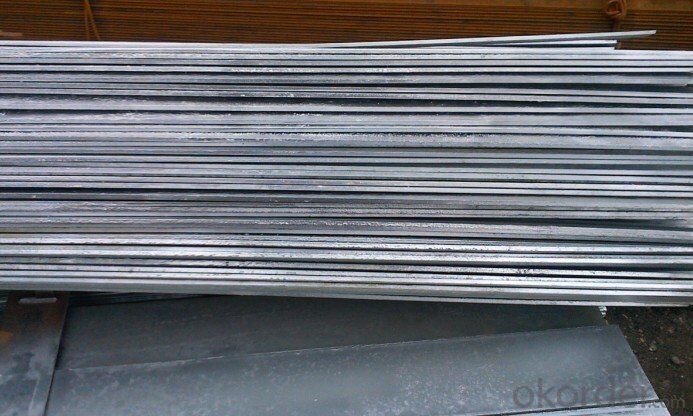

JIS G3101 SS400 Flat Spring Steel with high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

OKorder is offering Flat Spring Steel with high quality at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Flat Spring Steel with high quality are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Flat Spring Steel with high qualityare durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Description:

Specification of Flat Spring Steel with high qualityl:

-Material: 55Si2Mn

-Production: Hot rolled or cold rolled

-Standard: GB/T 1222-1984

-Type: Spring Steel

-Alloy or no: Alloy

-Tensile Strength σb (MPa): ≥1274(130)

-Yield Strength σs (MPa): ≥1176(120)

-Elongation δ10(%): ≥6

-Percentage reduction of area: ψ (%): ≥30

-Hardness:

1, Hot rolled, ≤302HB

2, Cold drawn + Heat treatment: ≤321HB

Usage/Applications of Flat Spring Steel:

-Elements Si and Mn improve elasticity strength, hardenability, and the ratio of yield point and tensile strength. but the decarburization tendency is a little large,

-55Si2Mn Spring Steel can be used as vibration damper leaf spring and spiral spring of cars and tractors.

-Heat-resisting spring below 250 degrees.

Packaging & Delivery of Flat Spring Steel:

-Packing Detail: The products can be packed in bundles by steel wires.

-Marks:

1, Tag marks: the tag marks will be tied up to each bundle of the products. The information is usually including supplier’s logo and name, product name, made in China, products’ specifications, the painted color and other information requested by customers.

2, Color marks: we will paint both ends of the bundles of these products to make sure that they are more evident. It’s will be more convenient for the customers to distinguish them at the destination port.

-Delivery Detail:

1, Delivery time: 30~45 working days after receive buyer’s T.T. or L/C.

2, Delivery status should be written in the contract. (Heat treatment or no)

Payment:

-Invoicing on theoretical weight or actual weight as customer’s request.

-FOB, CFR or CIF.

-Regular terms of payment:

1, 30% payment in advance, the remaining balance (70% payment) against the copy of B/L. 100% payment before shipment.

2, 30% payment in advance, the remaining balance (70% L/C) against the copy of B/L. 100% payment before shipment.

3, Negotiable.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Image:

- Q: How do you store and transport steel flat bars safely?

- To ensure the safe storage and transportation of steel flat bars, it is essential to follow several important steps: 1. Stack the bars correctly: Proper stacking is crucial in preventing damage. Align each layer of bars horizontally and evenly, distributing the weight evenly across the stack to maintain its structural integrity. 2. Provide adequate support: Prevent sagging or bending of the bars by using sturdy supports such as appropriately sized pallets or racks. Ensure that the supports can handle the weight and size of the bars. 3. Secure the stack: To avoid shifting during transportation, securely fasten the stack with straps or bands. Make sure they are tightly fastened, ensuring that the bars remain in place throughout transit. 4. Take protective measures: Steel flat bars are vulnerable to corrosion, especially when exposed to moisture. Protect them from environmental elements during storage and transportation by using protective covers or wrapping the bars in moisture-resistant materials to prevent rust or damage. 5. Use proper lifting and handling techniques: When moving the bars, employ suitable lifting equipment like forklifts or cranes to prevent accidents or injuries. Ensure that the equipment is capable of handling the weight of the bars and that operators are trained in safe lifting practices. 6. Considerations for long-distance transportation: If transporting the bars over long distances, it may be necessary to utilize specialized shipping containers or trucks equipped to handle heavy loads and provide adequate protection from external elements. By adhering to these guidelines, you can minimize the risk of damage, accidents, and corrosion, ensuring the safe delivery of steel flat bars to their intended destination.

- Q: What are the different types of edge finishes for steel flat bars?

- There are several types of edge finishes for steel flat bars, including mill edge, sheared edge, flame-cut edge, and machined edge. The mill edge is the standard finish, resulting from the hot rolling process. Sheared edge is achieved by cutting the bar with a shear, leaving a rough and uneven edge. Flame-cut edge is created by using a high-temperature flame to cut the bar, resulting in a rough and oxidized edge. Machined edge is achieved by using a cutting tool to remove material, resulting in a smooth and precise edge.

- Q: Are steel flat bars available in different profiles?

- Yes, steel flat bars are available in different profiles. The profiles refer to the shape or design of the flat bar. Some common profiles include square edge, round edge, and chamfered edge. Square edge flat bars have sharp corners and straight edges, making them suitable for various applications such as construction, manufacturing, and fabrication. Round edge flat bars have rounded corners and edges, which provide a smoother and safer finish, often used for architectural purposes or in industries where safety is a concern. Chamfered edge flat bars have beveled edges, allowing for a more aesthetically pleasing appearance and easy handling. These different profiles offer versatility and allow for customization based on specific project requirements.

- Q: Can steel flat bars be used for load-bearing applications?

- Yes, steel flat bars can be used for load-bearing applications. Steel is known for its high strength and durability, making it suitable for supporting heavy loads. Flat bars provide a stable and solid base for load-bearing structures, such as beams, frames, and trusses, ensuring stability and structural integrity.

- Q: How do you prevent rusting on steel flat bars?

- To prevent rusting on steel flat bars, there are several steps you can take: 1. Keep the bars dry: Moisture is a major contributor to rusting. Ensure that the flat bars are stored in a dry environment and avoid exposing them to water or excessive humidity. 2. Apply a protective coating: Applying a protective coating is an effective way to prevent rust formation. Options include paint, varnish, or a specialized rust-resistant coating. Make sure to choose a coating that is specifically designed for steel and can withstand the intended use of the flat bars. 3. Use galvanized steel: Galvanization is a process that involves coating steel with a layer of zinc. This protective layer acts as a barrier against moisture and prevents rusting. Galvanized steel flat bars are highly resistant to corrosion and can be a great choice if rust prevention is a priority. 4. Maintain proper ventilation: If the steel flat bars are used in an environment with high humidity or exposure to chemicals, adequate ventilation is crucial. Proper airflow helps to prevent the accumulation of moisture, reducing the risk of rust formation. 5. Regular cleaning and inspection: Regularly cleaning the steel flat bars and inspecting them for any signs of rust or damage is essential. If any rust spots are detected, they should be promptly addressed to prevent further corrosion. 6. Store the bars properly: When storing steel flat bars, ensure they are kept in a dry location away from any potential sources of moisture. Consider using storage racks or shelves to prevent direct contact with the ground or other surfaces that may accumulate moisture. By following these preventive measures, you can significantly reduce the chances of rusting on steel flat bars and prolong their lifespan.

- Q: What are the different methods of surface hardening for steel flat bars?

- Steel flat bars can be surface hardened using various methods, each with its own unique advantages and applications. Some commonly used techniques include: 1. Flame Hardening: By heating the steel flat bar's surface with a flame and rapidly quenching it, a hardened outer layer is formed while maintaining a tough core. Flame hardening is suitable for larger flat bars and provides good wear resistance. 2. Induction Hardening: This method involves heating the steel flat bar's surface using an alternating electromagnetic field, followed by quenching. Induction hardening allows for precise control over the hardened depth and is ideal for flat bars with complex geometries or smaller sizes. 3. Nitriding: Nitriding exposes the steel flat bar to a nitrogen-rich environment at elevated temperatures. This process creates a hard nitride layer on the surface, offering excellent wear and corrosion resistance. Nitriding is commonly used for flat bars that require superior surface hardness. 4. Carburizing: Carburizing entails heating the steel flat bar in a carbon-rich environment, enabling carbon atoms to penetrate the surface. The bar is then quenched to achieve hardness. Carburizing provides high wear resistance and is suitable for flat bars that require a hardened surface layer. 5. Carbonitriding: This method combines the benefits of carburizing and nitriding. The steel flat bar is heated in an atmosphere rich in both nitrogen and carbon, resulting in a hard surface layer with improved wear and corrosion resistance. Carbonitriding is commonly used for flat bars that necessitate a combination of hardness and toughness. 6. Laser Hardening: Laser hardening employs a high-energy laser beam to heat and rapidly cool the steel flat bar's surface, creating a hardened layer. This process allows for precise control over the hardened area and is suitable for flat bars with intricate designs or localized hardening requirements. Each surface hardening method has its own advantages and limitations, and the choice depends on the specific requirements of the steel flat bar application, such as desired hardness, wear resistance, and dimensional complexity.

- Q: Can steel flat bars be anodized or plated with other metals?

- Yes, steel flat bars can be anodized or plated with other metals. Anodizing involves creating an oxide layer on the surface of the steel, while plating involves depositing a thin layer of another metal onto the steel surface. Both processes can enhance the appearance, durability, and corrosion resistance of steel flat bars.

- Q: Can steel flat bars be used for making brackets or brackets?

- Yes, steel flat bars can definitely be used for making brackets or brackets. Steel is a strong and durable material, making it suitable for various applications, including bracket manufacturing. Steel flat bars can be easily shaped, cut, and welded to create brackets of different sizes and shapes. They provide stability and support, making them ideal for holding objects or providing structural reinforcement. Additionally, steel's corrosion resistance makes it a reliable choice for brackets that may be exposed to moisture or other harsh conditions.

- Q: Are steel flat bars commonly used in the construction of sports facilities?

- Yes, steel flat bars are commonly used in the construction of sports facilities. They are often utilized for structural support, such as in the construction of bleachers, fencing, and overhead structures. Steel flat bars provide strength and durability, making them suitable for the demanding needs of sports facilities.

- Q: Are steel flat bars corrosion resistant?

- Yes, steel flat bars can be corrosion resistant depending on the type of steel used. Some stainless steel grades, such as 304 and 316, have excellent corrosion resistance due to their high chromium and nickel content. However, carbon steel flat bars are more prone to corrosion and should be protected with coatings or regular maintenance to prevent rust.

Send your message to us

JIS G3101 SS400 Flat Spring Steel with high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords