Feutre Géotextile Castorama - Isolation Filament Polypropylène pour la Construction Routière

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

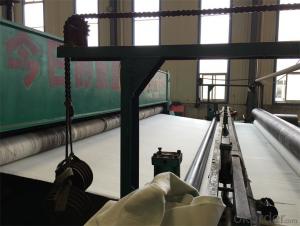

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

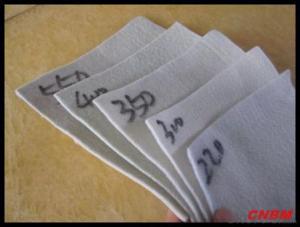

Specification

Property:

1.High strength ; low deformation.

2. Durability: steady property, not easy to resolved, airslaked and keep the original property long term.

3. Anti-erosion: anti-acid, anti-alkali, resist insects and mould.

4. Permeability: the woven geotextile can control the sieve size to retain permeability.

Application

It is widely used in river , coast ,harbour, highway ,railway, wharf, tunnel, bridge and other geotechnical engineering. The woven geotextile is a invaluable product and can be separation, reinforcement , protection and other.

Product size

Width <=6.0m, length: 50(at request)

♦ Shipping:By sea or as your customize

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

- Q: Are geotextiles suitable for use in erosion control blankets?

- Yes, geotextiles are suitable for use in erosion control blankets. They are designed to provide soil stabilization and erosion control by allowing water to pass through while retaining soil particles. Geotextiles help prevent soil erosion, promote vegetation growth, and enhance the overall effectiveness of erosion control blankets.

- Q: Can geotextiles be used for reinforcement of embankments?

- Yes, geotextiles can be used for the reinforcement of embankments. They are commonly used in civil engineering projects to improve the stability, strength, and longevity of embankments. Geotextiles provide separation, filtration, and reinforcement functions, helping to prevent erosion, soil movement, and structural failure.

- Q: Can geotextiles be used in coastal protection?

- Yes, geotextiles can be used in coastal protection. Geotextiles are often employed as a part of coastal erosion control measures to stabilize sandy or loose soils. They can be used to create barriers that prevent erosion by filtering out sediment and allowing water to drain, while also providing reinforcement to the soil and preventing it from being washed away by waves and currents.

- Q: Geotextile cloth how many square feet

- Geotextile laying - including the labor costs (according to geotextile specifications and laying conditions and requirements are different), material costs (specific quality requirements and thickness, are not the same ..), mechanical use costs (such as transport, sewing System, hoisting, etc.). The price is different. Sometimes the construction of our geotextile laying, the price per square meter from 9 yuan to 50 yuan range.

- Q: How do geotextiles help with load distribution in pavement systems?

- Geotextiles provide a reinforcing and stabilizing function in pavement systems by distributing applied loads more evenly across the underlying soil, reducing stress concentrations, and preventing the formation of cracks and deformations.

- Q: How do geotextiles contribute to soil stabilization?

- Geotextiles contribute to soil stabilization by providing a barrier that prevents soil erosion, while still allowing water to drain through. They distribute the weight of the load evenly, reducing the chances of soil compaction and settling. Additionally, geotextiles help in reinforcing the soil, increasing its shear strength and stability.

- Q: There is no geotextile in the sand filter with the biological retention

- You can use geotextiles

- Q: What are the materials used in geotextile production?

- Geotextiles are typically produced using a variety of materials, including synthetic fibers such as polypropylene, polyester, and polyethylene. These materials are chosen for their durability, strength, and resistance to environmental conditions. Natural fibers like jute and coir can also be used in certain geotextile applications. Additionally, some geotextiles may incorporate additives or coatings to enhance their performance and stability.

- Q: What are the physical properties of geotextiles?

- Geotextiles are engineered fabrics that possess various physical properties. They are typically lightweight and flexible, allowing for easy handling and installation. Geotextiles also exhibit high tensile strength, enabling them to withstand stress and strains that occur during construction or erosion control applications. These fabrics are permeable, allowing water and gases to pass through while retaining soil particles. Additionally, geotextiles are resistant to UV degradation, chemicals, and biological degradation, ensuring their durability and longevity in outdoor environments.

- Q: How do geotextiles help in stabilizing slopes?

- Geotextiles help in stabilizing slopes by acting as a barrier that prevents soil erosion, while still allowing water to drain through. They provide reinforcement to the soil, increasing its stability and reducing the chances of slope failure. Geotextiles also aid in vegetation growth on slopes, which further contributes to slope stability.

Send your message to us

Feutre Géotextile Castorama - Isolation Filament Polypropylène pour la Construction Routière

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords