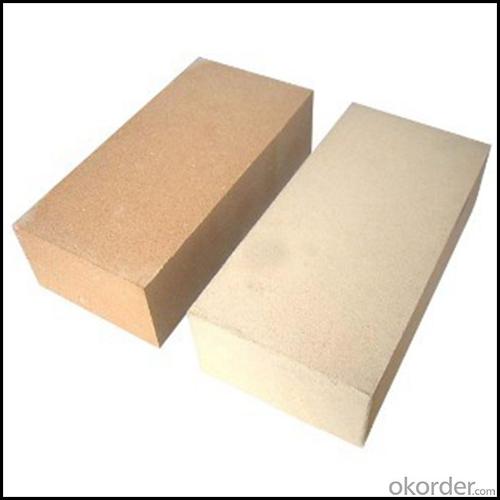

Insulating Fire Clay Refractory Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0.01

- Supply Capability:

- 2400 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Acid Resistant Brick

CMAX firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

High alumina refractory brick is dense shaped refractory material. With high refractoriness and mechanical behavior under high temperature, refractory brick is the necessary material of high-temperature services, mainly used for industrial furnaces and kilns and thermal equipment.

High alumina refractory brick has wide applications, mainly used in metallurgy, construction(cement and glass), petroleum, chemical industry, electric power and machine building.

Features

1) Good thermal shock resistance

2) High-temperature endurable

3) Good thermal insulation

4) The using temperature is 1600 c

5) Phosphate high alumina bricks,iso

6) High strength

7) Low thermal conductivity

8) Widely used in cement kiln.

9) Low creeping rate

10) High pressure

11) Excellent thermal shock resistance

12) High quality fireclay clinker

Application

Iron & Steel Making Industry

Blast Furnace,Hot Blast Furnace(stove),Pellet Shaft Furnace,Hot Metal Ladle,Steel

Ladle, Tundish,Heating Furnace,Saking Pit Furnace,Heat Treatment Furnance.Refining Furnance,Reheating Furnance,Metal Mixter Furnance,Annealing Furnace,Cupola Furnace,Electric Arc Furnace,Induction Furnace,AOD Furnace,

cupola furnace,electric arc furnace,induction furnace,AOD furnace,VOD furnace,etc thermal technology equipment .

Non-Ferrous Metal Industry

Smelting furnace,refining furnace,reverberatory furnace,converter furnace

Building Materials Industy

cement kiln,glass kiln,ceramic kiln, lime kilns, kiln car,tunnel kiln

Energy & Incineration

Such as coke oven,general boiler,power generation boiler,circulating fluidized bed boiler,electric furnace,carbon roasting furnace,waste incinerators

Data Sheet

Classification Temperature (℉/℃) | 3000/1650 |

Bulk Density (g/cm3 ) | ≤1.0 |

Thermal Conductivity | |

800℃, W/m.K | ≤0.39 |

1000℃, W/m.K | ≤0.43 |

1200℃, W/m.K | ≤0.48 |

Reheating Linear Change (%) | 1550℃×12h |

≤0.9 | |

Chemical Composition (%) | |

Al2O3 | ≥75 |

Fe2O3 | ≤0.5 |

Packaging & Shipping

Packaging Details:Be packed in fumigated wooden pallets

Delivery Detail: 30 days after order

Our Services

Optimum solution and product supply of refractories for high temperature industries, such as iron steel, non-ferrous, petrochemical and building materials.

Engineering design, contract and consult for refractories, and civil architecture design.

Research, development, manufacture and sale of superhard materials.

R&D, manufacture and sale of special packing materials for export.

Inspection, supervision and arbitration of refractories.

Consultation and services in refractories information.

Training and cultivation of high-level talents in refractories profession

Sales Network

Company Information

CNBM (China National Building Material) Group is the largest comprehensive building materials group in China that in integrate scientific research, manufacturing and logistics into one entity. The largest building materials and equipment specialists in China. Upon State Council approval, today CNBM owned more than 300 subordinate manufacturing factories and servicing companies. There are 6 fully owned public listed companies and 11 partially owned with substantial shares public listed companies. In many of these fields, CNBM is playing the leading role in the building industry in the country.

FAQ

1. Which products do you have?

We have all kinds of refractory brick, castable, mortar, cement, ceramic fiber products, etc.

Or you could browse our products to choose what you need.

2. Can you give me a brief introduction of the application of your products?

We are mainly specializing in the refractory materials in iron and steel, cement, glass, ceramics, petrochemical, electric power Industry, etc.

3. If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc. If any question, please contact us freely.

- Q: Can insulating fire bricks be painted or coated?

- Insulating fire bricks have a specific design to endure high temperatures and offer efficient thermal insulation. Although it is technically feasible to apply paint or coating on them, it is generally discouraged. This is due to the possibility that the paint or coating might not withstand the extreme temperatures that the fire bricks encounter, leading to deterioration or even a potential fire risk. Furthermore, the act of painting or coating the fire bricks can diminish their insulating properties, defeating the initial purpose of their usage. Consequently, it is recommended to utilize insulating fire bricks in their original state, without any supplementary paint or coating.

- Q: Can insulating fire bricks be used in the construction of lime recovery kilns?

- Yes, insulating fire bricks can be used in the construction of lime recovery kilns. Lime recovery kilns are high-temperature industrial furnaces used to convert limestone (calcium carbonate) into lime (calcium oxide) through a process called calcination. Insulating fire bricks are designed to withstand high temperatures and provide excellent thermal insulation. They are made from lightweight refractory materials, such as clay or silica, and have low thermal conductivity. In lime recovery kilns, where temperatures can reach up to 900-1200 degrees Celsius, insulating fire bricks can be used to line the walls, floors, and roofs of the kiln. Their high insulating properties help to reduce heat loss and improve energy efficiency by keeping the heat inside the kiln. This leads to lower fuel consumption and cost savings. Furthermore, insulating fire bricks have good resistance to thermal shock, which is crucial in the lime recovery process. The kilns undergo repeated heating and cooling cycles, and the bricks must be able to withstand these temperature changes without cracking or disintegrating. Overall, insulating fire bricks are a suitable choice for lime recovery kilns due to their ability to withstand high temperatures, provide thermal insulation, and resist thermal shock.

- Q: Can insulating fire bricks be used as a heat shield?

- Yes, insulating fire bricks can be used as a heat shield. Insulating fire bricks are designed to have excellent thermal insulation properties, which means that they can effectively block and reflect heat. They are commonly used in applications where heat needs to be contained or redirected, such as in fireplaces, kilns, furnaces, and industrial ovens. The insulating properties of these bricks allow them to reduce heat transfer, providing a barrier between the intense heat source and the surrounding environment. Additionally, they have high melting points and can withstand high temperatures, making them suitable for use as a heat shield. However, it is important to note that the effectiveness of insulating fire bricks as a heat shield may vary depending on the specific requirements and conditions of the application.

- Q: Are insulating fire bricks fire-rated?

- Yes, insulating fire bricks are fire-rated. They are specially designed to withstand high temperatures and provide excellent insulation properties, making them suitable for use in fireplaces, kilns, and other applications that involve exposure to extreme heat.

- Q: Do insulating fire bricks provide sound insulation as well?

- No, insulating fire bricks are primarily designed to provide thermal insulation and are not specifically designed for sound insulation.

- Q: Do insulating fire bricks require any special installation techniques?

- Special installation techniques are necessary for insulating fire bricks. These bricks are designed to offer excellent thermal insulation, so proper installation is essential for optimal performance. To begin, it is crucial to have a clean and debris-free installation surface. This creates a strong and stable foundation for the bricks. Afterward, it is important to use a suitable refractory mortar or adhesive to secure the bricks in place. This mortar should be specifically designed for high-temperature applications and capable of withstanding thermal expansion and contraction during heating and cooling cycles. During installation, attention should be given to filling the joints between the bricks with mortar. This prevents heat loss and maintains the insulating properties of the bricks. Furthermore, careful stacking and alignment of the insulating fire bricks is necessary to ensure a tight fit and minimize gaps. This maximizes insulation and prevents heat leakage. Lastly, it is advisable to consult the manufacturer's guidelines and follow their recommended installation techniques. Different types of insulating fire bricks may have specific requirements that must be adhered to for proper installation. In summary, insulating fire bricks demand special installation techniques to ensure their effectiveness and longevity. Following proper installation practices will enhance the thermal insulation properties of these bricks and optimize their performance.

- Q: Can insulating fire bricks be used for insulation in heat recovery systems?

- Yes, insulating fire bricks can be used for insulation in heat recovery systems. Insulating fire bricks are specifically designed to withstand high temperatures and provide effective thermal insulation. They have low thermal conductivity, which means they can minimize heat loss and maximize heat recovery in a system. These bricks are often used in various industrial applications such as kilns, furnaces, and ovens, where temperature control and energy efficiency are important. Therefore, they can be a suitable choice for insulating heat recovery systems, helping to optimize the recovery and utilization of waste heat.

- Q: Do insulating fire bricks have a high thermal shock resistance?

- Yes, insulating fire bricks typically have a high thermal shock resistance. These bricks are specifically designed to withstand rapid changes in temperature without cracking or breaking. They are made from lightweight refractory materials that have low thermal conductivity, which helps to minimize heat transfer and prevent thermal stress. Additionally, insulating fire bricks often go through a firing process that further enhances their thermal shock resistance. Overall, these bricks are well-suited for applications where they are exposed to extreme temperature fluctuations, making them a reliable choice for insulation in high-temperature environments.

- Q: Can insulating fire bricks be used for insulation in heat treatment furnaces?

- Indeed, insulation in heat treatment furnaces can be achieved through the utilization of insulating fire bricks. These bricks are specially engineered to endure extreme temperatures and offer exceptional thermal insulation properties. With their low thermal conductivity, they effectively trap heat within the furnace. Moreover, their lightweight composition facilitates effortless handling and installation. Insulating fire bricks find widespread application in diverse heat treatment procedures, including annealing, tempering, and hardening, guaranteeing utmost heat retention and energy efficiency within the furnace.

- Q: What is the thermal insulation performance of aerated bricks?

- Aerated brick light weight, heat preservation, heat insulation, sound insulation, easy processing, using a variety of hybrid material production, rich production of raw materials, especially the use of fly ash, and comprehensive utilization of industrial waste, environmental pollution, saving farmland, have a good social and economic benefits, is an alternative to the traditional solid clay brick ideal wall materials. Gongyi Machinery Factory is specialized in producing aerated brick equipment manufacturers.

Send your message to us

Insulating Fire Clay Refractory Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0.01

- Supply Capability:

- 2400 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords