Insulating Fire Brick - Refractory Mullite Insulating Refractory Brick JM 29

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 20 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

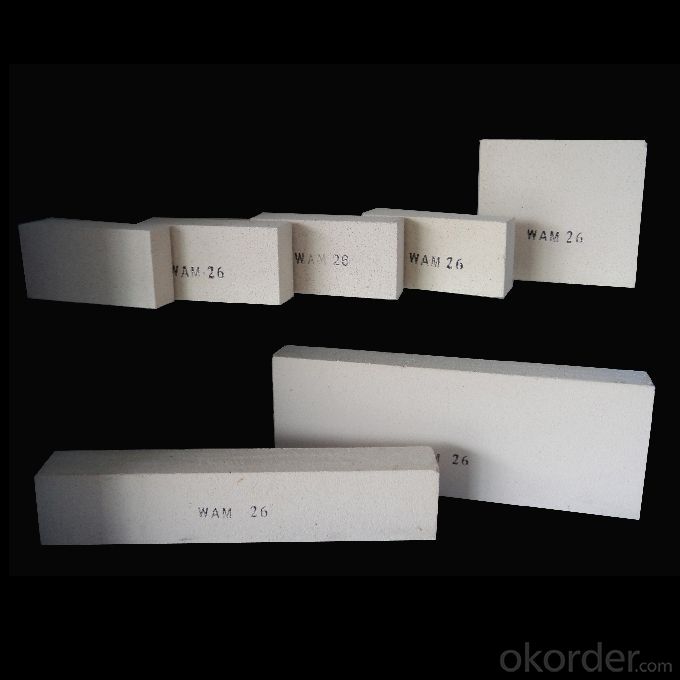

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

1. Lower content of iron, alkaline and impurities, good high temperature properties.

2. Homogeneous structure, light weight, energy saving because lower heat storage in the furnace during cooling cycles.

3. High strength, good thermal shock resistance under high temperature.

4. Precise sizes due to grinding and shaping after sintering, which meets the requirement of construction.

5. Max service temp: Up to 1730C (3160F)

Feature

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

Application of Insulating brick

Metallurgical Industry: blast furnace, hot blast furnace, heating furnace, etc..

Petrochemical Industry: ethylene cracking furnace, hydrogen furnace, the main furnace, heating furnace, etc..

Ceramic industry: roller kiln, kiln, etc..

Glass industry: glass furnace regenerator, etc.

Carbon industry: carbon furnace, etc..

Aluminum electrolysis industry: aluminum reduction cell, etc.

Other industries: tunnel kiln, shuttle kiln, etc.

Advantages of heat insulation brick

Low thermal conductivity: many air holes will bring good thermal insulation effect, energy saving.

High crushing strength: high crushing strength, volume stability.

Low heat storage: small heat storage, absorb more heat, energy-saving effect is obvious.

Technical Data

ITEM | GJM30 | GJM28 | GJM26 | GJM23 |

Classification Temperature, ℉/℃ | 3000/1650 | 2800/1540 | 2600/1430 | 2300/1260 |

Bulk Density,g/cm³ | ≤1.0 | ≤0.9 | ≤0.8 | ≥0.5 |

Reheating Linear Change, % | ≤0.9 (1550℃,12 h) | ≤0.8 (1510℃,12 h) | ≤0.7 (1410℃,12 h) | ≤0.5 (1230℃,12 h) |

Al2O3 Content, % | ≥75 | ≥65 | ≥55 | ≥45 |

Fe2O3 Content, % | ≤0.5 | ≤0.6 | ≤0.7 | ≤1.0 |

Thermal Conductivity: | ||||

800℃, w/m.k | ≤0.39 | ≤0.37 | ≤0.35 | ≤0.18 |

1000℃, w/m.k | ≤0.43 | ≤0.41 | ≤0.39 | ≤0.20 |

1200℃, w/m.k | ≤0.48 | ≤0.46 | ≤0.43 | --- |

Insulating brick

- Q: Are insulating fire bricks suitable for use in chimneys and fireplaces?

- Yes, insulating fire bricks are suitable for use in chimneys and fireplaces. They have excellent thermal insulation properties, which helps to retain heat and prevent the transfer of excessive heat to the surrounding structure. This makes them a safe and efficient choice for lining chimneys and fireplaces, as they can withstand high temperatures and reduce the risk of heat damage.

- Q: Can insulating fire bricks be used in the construction of thermal insulation floors?

- Yes, insulating fire bricks can be used in the construction of thermal insulation floors. These bricks are designed to provide excellent thermal insulation properties, making them suitable for use in floor applications where insulation is required.

- Q: Can insulating fire bricks be used in brick ovens?

- Yes, insulating fire bricks can be used in brick ovens. They are designed to withstand high temperatures and have excellent heat insulation properties, making them suitable for use in brick ovens to help retain and distribute heat evenly.

- Q: Are insulating fire bricks resistant to nitric acid?

- Insulating fire bricks usually lack resistance against nitric acid, a highly corrosive substance that can dissolve various materials, including specific types of fire bricks. Although insulating fire bricks are intended for enduring high temperatures and providing thermal insulation, they may not possess the required chemical resilience to withstand the corroding impact of nitric acid. When anticipating exposure to nitric acid, it is recommended to employ materials specifically engineered for acid resistance in such situations.

- Q: Can insulating fire bricks be used in wood-fired kilns?

- Yes, insulating fire bricks can be used in wood-fired kilns. Insulating fire bricks are specifically designed to withstand high temperatures and provide insulation, making them suitable for use in wood-fired kilns where temperatures can reach extreme levels.

- Q: Can insulating fire bricks be used in the construction of furnaces?

- Yes, insulating fire bricks can be used in the construction of furnaces. These bricks are specifically designed to withstand high temperatures and provide excellent insulation, making them ideal for lining the walls of furnaces. They help to reduce heat loss, increase energy efficiency, and improve overall performance of the furnace.

- Q: Can insulating fire bricks be used for structural purposes?

- The main purpose of insulating fire bricks is to offer insulation, rather than providing structural support. Although they can endure high temperatures and resist thermal shock, they are not usually meant to bear heavy loads or function as load-bearing elements in structural applications. Insulating fire bricks are more frequently utilized in scenarios that require thermal insulation, such as lining kilns, furnaces, and fireplaces. For structural uses, it is generally advisable to employ refractory bricks or other materials that are specifically designed to offer strength and durability under load.

- Q: Are insulating fire bricks easy to cut and shape?

- Indeed, cutting and shaping insulating fire bricks proves to be relatively simple. These bricks consist of lightweight refractory materials like ceramic fibers, enabling them to be more manageable when compared to traditional fire bricks. Common tools such as saws, knives, or chisels can be employed to cut and shape these insulating fire bricks. Due to their lightweight composition, they can be easily maneuvered and positioned, facilitating more accurate cuts and shapes. Moreover, if necessary, openings or specific designs can be effortlessly drilled or carved into these bricks. Overall, the convenience of cutting and shaping insulating fire bricks makes them an ideal choice for various applications in construction, insulation, and fireproofing.

- Q: Can insulating fire bricks be cut or shaped to fit specific applications?

- Yes, insulating fire bricks can be cut or shaped to fit specific applications. Insulating fire bricks are made from lightweight refractory materials, typically ceramic fibers or lightweight aggregates, which allows them to be easily cut or shaped without compromising their structural integrity. They can be cut with a saw, knife, or other cutting tools to fit specific dimensions or shapes required for various applications, such as lining kilns, furnaces, or fireplaces. Additionally, insulating fire bricks can be shaped by using molds or by hand molding during the manufacturing process. This flexibility in cutting and shaping makes insulating fire bricks highly versatile and suitable for a wide range of industrial and residential applications.

- Q: How do insulating fire bricks affect the overall efficiency of a heating system?

- The efficiency of a heating system is greatly improved by insulating fire bricks, which have a crucial role to play. These bricks are specifically designed to have low thermal conductivity, allowing them to effectively trap and retain heat within the system. The use of insulating fire bricks significantly reduces heat loss from the system, resulting in improved energy efficiency. One of the main advantages of insulating fire bricks is their ability to minimize heat transfer through conduction. These bricks have a high resistance to heat flow, acting as a barrier that prevents heat from escaping the system. This is particularly important in areas where high temperatures are generated, such as furnaces or kilns. By containing the heat within the system, insulating fire bricks enable the heating system to maintain a consistent temperature, reducing the need for excessive energy consumption to compensate for heat loss. In addition, insulating fire bricks also help decrease heat loss through radiation. These bricks have a high emissivity, meaning they radiate less heat than other materials. As a result, the heat produced by the system is focused on the desired area, rather than being wasted through radiation. This not only improves the efficiency of the heating system but also ensures that the heat is effectively utilized for its intended purpose. Another advantage of insulating fire bricks is their ability to withstand high temperatures without deteriorating. These bricks are composed and manufactured in a way that allows them to handle extreme heat levels, maintaining their structural integrity over time. This durability is crucial for the longevity of the heating system and ensures that the insulating properties of the bricks remain intact. To summarize, insulating fire bricks have a significant positive impact on the overall efficiency of a heating system. Their low thermal conductivity, ability to minimize heat transfer through conduction and radiation, and durability at high temperatures all contribute to reducing heat loss and improving energy efficiency. By incorporating insulating fire bricks into a heating system, users can enjoy a more efficient and cost-effective heating solution.

Send your message to us

Insulating Fire Brick - Refractory Mullite Insulating Refractory Brick JM 29

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 20 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords