Insulating Fire Brick - Lightweight Insulating Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 2000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

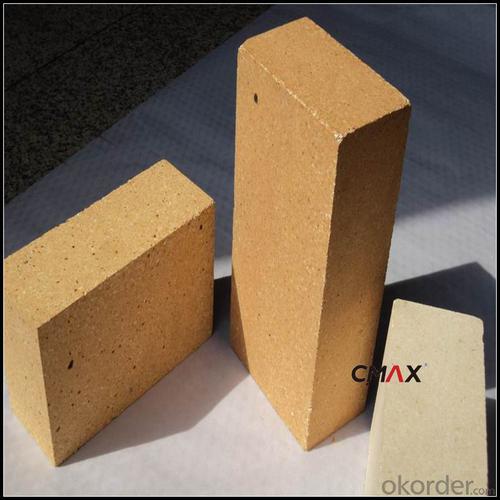

Light Weight Insulating Brick

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

Light Weight Insulating Brick Features

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

Light Weight Insulating Brick Application

Hot air duct ling

Shuttle kiln with high gas velocity

Laboratory furnace

Kiln car insulation

Light Weight Insulating Brick Data Sheet

Classification Temperature (℉/℃) | 3000/1650 |

Bulk Density (g/cm3 ) | ≤1.0 |

Thermal Conductivity | |

800℃, W/m.K | ≤0.39 |

1000℃, W/m.K | ≤0.43 |

1200℃, W/m.K | ≤0.48 |

Reheating Linear Change (%) | 1550℃×12h |

≤0.9 | |

Chemical Composition (%) | |

Al2O3 | ≥75 |

Fe2O3 | ≤0.5 |

Packaging & Shipping

Packaging Details:Be packed in fumigated wooden pallets

Delivery Detail: 30 days after order

Our Services

Optimum solution and product supply of refractories for high temperature industries, such as iron steel, non-ferrous, petrochemical and building materials.

Engineering design, contract and consult for refractories, and civil architecture design.

Research, development, manufacture and sale of superhard materials.

R&D, manufacture and sale of special packing materials for export.

Inspection, supervision and arbitration of refractories.

Consultation and services in refractories information.

Training and cultivation of high-level talents in refractories profession

Sales Network

Company Information

CNBM (China National Building Material) Group is the largest comprehensive building materials group in China that in integrate scientific research, manufacturing and logistics into one entity. The largest building materials and equipment specialists in China. Upon State Council approval, today CNBM owned more than 300 subordinate manufacturing factories and servicing companies. There are 6 fully owned public listed companies and 11 partially owned with substantial shares public listed companies. In many of these fields, CNBM is playing the leading role in the building industry in the country.

FAQ

1. Which products do you have?

We have all kinds of refractory brick, castable, mortar, cement, ceramic fiber products, etc.

Or you could browse our products to choose what you need.

2. Can you give me a brief introduction of the application of your products?

We are mainly specializing in the refractory materials in iron and steel, cement, glass, ceramics, petrochemical, electric power Industry, etc.

3. If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc. If any question, please contact us freely.

- Q: Are insulating fire bricks suitable for use in the construction of lime kilns?

- Insulating fire bricks are indeed suitable for constructing lime kilns. These bricks are designed specifically to possess low thermal conductivity, enabling them to retain heat and avoid heat loss. This feature is crucial in lime kilns as they necessitate high temperatures for effectively converting limestone into lime. The utilization of insulating fire bricks facilitates the better maintenance of the kiln's generated heat, leading to enhanced energy efficiency and reduced fuel consumption. Moreover, these bricks are lightweight and convenient to handle, making them the perfect choice for lime kiln construction. All in all, insulating fire bricks are a dependable and efficient option for building lime kilns.

- Q: Can insulating fire bricks be used in chimneys?

- Insulating fire bricks are indeed suitable for chimneys. Their purpose lies in enduring high temperatures, rendering them an excellent option for lining chimneys. Not only do they possess superb thermal insulation properties, thus minimizing heat loss and enhancing chimney efficiency, but they are also lightweight and simple to install. Nonetheless, it is crucial to acknowledge that insulating fire bricks may not be suitable for every chimney type. To ascertain the appropriate materials for your individual chimney requirements, consulting a professional or chimney specialist is highly recommended.

- Q: Can insulating fire bricks be used in copper smelting furnaces?

- Yes, insulating fire bricks can be used in copper smelting furnaces. Insulating fire bricks are designed to withstand high temperatures and provide excellent insulation, making them ideal for use in furnaces. They are made from materials that can handle the extreme heat generated during the smelting process and can effectively retain and reflect heat back into the furnace. This helps to maintain the desired temperature and improve energy efficiency. Additionally, insulating fire bricks can help to reduce heat loss, resulting in faster and more efficient copper smelting. Therefore, using insulating fire bricks in copper smelting furnaces is a common practice in the industry.

- Q: Can insulating fire bricks be used for insulation in chemical reactors?

- Yes, insulating fire bricks can be used for insulation in chemical reactors. Insulating fire bricks are made from lightweight materials such as vermiculite or perlite, which have excellent thermal insulation properties. These bricks are designed to withstand high temperatures and can provide insulation in a variety of applications, including chemical reactors. Chemical reactors often operate at elevated temperatures, and maintaining a stable temperature is crucial for efficient and safe operation. By using insulating fire bricks as insulation in chemical reactors, heat loss can be minimized, leading to better energy efficiency and cost savings. Additionally, insulating fire bricks can help to reduce the temperature gradient within the reactor, ensuring uniform heat distribution and enhancing the overall performance of the reactor. Furthermore, insulating fire bricks are resistant to chemical attack and can withstand the corrosive effects of various chemicals used in chemical reactions. This makes them suitable for use in chemical reactors where exposure to corrosive substances is common. In summary, insulating fire bricks are an excellent choice for insulation in chemical reactors. They provide superior thermal insulation, can withstand high temperatures, and are resistant to chemical attack. Using insulating fire bricks in chemical reactors can contribute to improved energy efficiency, temperature stability, and overall performance of the reactor.

- Q: Can insulating fire bricks be used in high-temperature kilns and furnaces?

- High-temperature kilns and furnaces can indeed utilize insulating fire bricks. These bricks are specifically designed to endure extreme heat and offer remarkable insulation properties. They consist of lightweight refractory materials, including clay and silica, which possess high melting points and low thermal conductivity. By effectively retaining heat, these bricks decrease energy loss and enhance the efficiency of the kiln or furnace. Moreover, insulating fire bricks exhibit excellent resistance to thermal shock, enabling them to withstand rapid temperature fluctuations without cracking or breaking. Consequently, they are well-suited for high-temperature applications that involve frequent heating and cooling cycles in kilns or furnaces. All in all, insulating fire bricks represent an ideal choice for insulating and safeguarding high-temperature kilns and furnaces.

- Q: Can insulating fire bricks be used in ladles and tundishes?

- Yes, insulating fire bricks can be used in ladles and tundishes. Insulating fire bricks are designed to provide high-temperature insulation and thermal stability, making them suitable for applications where heat retention is important. Ladles and tundishes are used in the steel and foundry industries to transport and pour molten metal, and the use of insulating fire bricks in these vessels can help to minimize heat loss and maintain the desired temperature of the metal. Additionally, insulating fire bricks can resist thermal shock and chemical corrosion, which are common challenges in these high-temperature environments. Therefore, using insulating fire bricks in ladles and tundishes can improve energy efficiency, reduce heat loss, and enhance the overall performance and longevity of these crucial equipment in the metal processing industry.

- Q: Can insulating fire bricks be used in refractory fibers?

- Insulating fire bricks are not suitable for use in refractory fibers. These bricks are solid and made from refractory materials, serving to insulate and retain heat in high-temperature scenarios. Conversely, refractory fibers are lightweight and flexible materials composed of ceramic or mineral fibers. They are employed for insulation and lining in a range of industrial applications, such as furnaces, kilns, and boilers. Due to their distinct properties and structures, these two materials are incompatible. Consequently, it is advisable to refrain from using insulating fire bricks in conjunction with refractory fibers.

- Q: What is the maximum temperature range of high temperature resistant insulation materials?

- Materials defined as physical and chemical properties that allow them to be used in a high temperature environment are called refractory materials. Refractory materials are widely used in metallurgy, chemical, petroleum, machinery manufacturing, silicate, power and other industrial fields, the largest amount of metallurgical industry, accounting for 50% ~ 60% of the total output.

- Q: Can insulating fire bricks be used as a structural component in a building?

- No, insulating fire bricks are not designed to be used as a structural component in a building. They are primarily used for their high insulation properties and are not strong enough to bear significant loads or provide structural support.

- Q: What is the thermal insulation performance of aerated bricks?

- Dongfeng steam free insulation performance of aerated brick brick production equipment; because the thermal conductivity of foamed concrete block is only 0.21W/M.K, which is 4 times the heat preservation effect of clay brick, cement brick 3 times, so it can improve the living comfort, hot summer and cold winter, can be greatly reduced the running time of the air conditioner,

Send your message to us

Insulating Fire Brick - Lightweight Insulating Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 2000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords