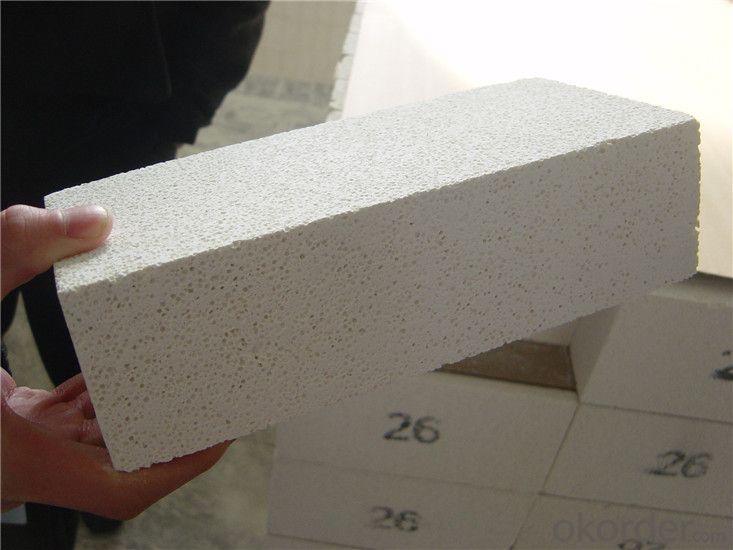

Insulating Fire Brick Lightweight Fire Clay

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CNBM conforms strictly to the requirements of ISO 9000 quality control system during the production. MSDS is also available if you want. The thermal insulation fire clay brick meet with the requirements of ASTM & JIS standards. So pls stay cool with our quality.

Insulating Fire Brick Technical index

Product No. | IFB70 | IFB60 | IFB50 | IFB40 |

Al2O3 | 68%-72% | 58%-62% | 48%-52% | 38%-40% |

Refractoriness (°C ) | ≥1790 | ≥1790 | ≥1790 | ≥1790 |

Bulk density (g/cm3) | 2.50-2.60 | 2.35-2.45 | 2.20-2.30 | 2.10-2.20 |

Apparent porosity (%) | 22 | 19-22 | 17-20 | 17-20 |

Cold Crushing strength (kg) | 480-510 | 450-480 | 430-450 | 390-430 |

Application

Insulating Fire Brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

2 units of Compact grain Abrasive pilot production lines

1 unit of high-end coated abrasives (abrasive cloth) production line

2 units of Boron Carbide production lines

3 large flexible crushing and sieving lines for grit production lines

2 units of 2000KVA furnaces for Boron Carbide fusion

6 units of 5000KVA-10000KVA dumping type electric arc furnaces for Brown Fused Alumina fusion

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

(4)Flexible payment: T/T L/C D/P D/A

(5)Professional marketing team and after-sale service

(6)Free sample

- Q: The project cost in hydropower No.3 shaft wall is solid brick or insulating brick?

- From the structure principle, hydropower shaft with solid brick, is to consider the safety performance of the structure.

- Q: Can insulating fire bricks be used in the construction of smelters or foundries?

- Yes, insulating fire bricks can be used in the construction of smelters or foundries. Insulating fire bricks have excellent thermal insulation properties and can withstand high temperatures, making them suitable for lining the walls and floors of smelters or foundries. They help to retain heat, improve energy efficiency, and protect the surrounding structures from extreme temperatures.

- Q: The insulation layer destroyed after use of cement paste and tiling

- Put on the insulating layer and paste it with cement.Some students worry about the insulation layer and the wall adhesive strength is not enough, do not worry about, now developers are building exterior insulation and then on top of the tiling. Because after finishing the insulation layer, the contractor should check the construction to do a pullout test, the purpose is to prevent the strength can not meet the requirements.

- Q: Can insulating fire bricks be used in the construction of lime kilns?

- Insulating fire bricks are perfectly suitable for the construction of lime kilns. These bricks are specifically designed to have low thermal conductivity, giving them exceptional insulation properties. As a result, they are ideal for use in lime kilns, which require high temperatures for the calcination process. Lime kilns typically operate within the temperature range of 900 to 1200 degrees Celsius. To ensure efficient and effective lime production, it is crucial to contain the intense heat generated during this process within the kiln. Insulating fire bricks play a vital role in achieving this by minimizing heat loss through the kiln walls, enabling higher energy efficiency and reducing operating costs. Moreover, insulating fire bricks offer the advantage of being lightweight and easy to handle, making them highly convenient for construction purposes. They can be easily shaped and cut to fit the specific design requirements of the lime kiln, ensuring a secure and tight fit. Furthermore, these fire bricks possess excellent resistance to thermal shock, which is of utmost importance in lime kilns where rapid temperature changes occur during the firing process. This resistance helps prevent cracking and structural damage, ensuring the longevity and durability of the kiln. To summarize, insulating fire bricks are an excellent choice for the construction of lime kilns due to their low thermal conductivity, lightweight nature, ease of shaping, and resistance to thermal shock.

- Q: Can insulating fire bricks be used for insulation in autoclaves?

- Yes, insulating fire bricks can be used for insulation in autoclaves. Insulating fire bricks are designed to have low thermal conductivity, which means they can effectively retain heat and withstand high temperatures. Autoclaves require insulation to maintain a consistent temperature and pressure, and insulating fire bricks can provide excellent insulation properties in these demanding conditions. Additionally, their high strength and durability make them suitable for withstanding the intense heat and pressure cycles that occur in autoclaves. Overall, insulating fire bricks are a reliable and effective choice for insulating autoclaves.

- Q: How do insulating fire bricks affect the overall noise insulation of a building?

- Insulating fire bricks can significantly enhance the noise insulation of a building. These bricks have excellent sound-absorbing properties due to their high density and ability to dampen sound vibrations. By reducing the transmission of airborne and impact noises, insulating fire bricks help create a quieter and more peaceful indoor environment.

- Q: Can insulating fire bricks be used in ceramic fiber boards?

- Insulating fire bricks have the potential to be utilized in ceramic fiber boards. They are commonly employed as a lining material for high-temperature purposes due to their ability to endure extremely high temperatures and offer exceptional thermal insulation. Conversely, ceramic fiber boards are lightweight and possess commendable thermal shock resistance, rendering them suitable for employment in diverse industrial and residential settings. When utilized in conjunction, insulating fire bricks can be positioned behind or around the ceramic fiber boards to augment their insulating properties and elevate overall thermal efficiency. The bricks have the capability to provide additional structural support and assist in retaining heat within the system, thereby enhancing energy efficiency and minimizing heat loss. Nevertheless, it is crucial to acknowledge that the compatibility of insulating fire bricks and ceramic fiber boards might fluctuate based on the specific application and requirements. It is advisable to seek guidance from manufacturers or industry professionals to ensure appropriate selection and installation of these materials according to your individual needs.

- Q: Do insulating fire bricks emit any harmful substances when heated?

- No, insulating fire bricks do not emit any harmful substances when heated.

- Q: Can insulating fire bricks be recycled?

- Certainly, it is possible to recycle insulating fire bricks. These bricks are commonly composed of clay, alumina, and silica, among other materials, that can be disassembled and repurposed. The recycling process entails crushing the bricks into smaller fragments, subsequently utilizing them as aggregate in diverse construction projects. By adopting this method, waste is diminished, and resources are conserved, rendering it an eco-friendly alternative to disposing of these bricks. Furthermore, certain companies provide dedicated recycling programs for insulating fire bricks, enabling both individuals and businesses to conveniently recycle them instead of resorting to landfills.

- Q: Are insulating fire bricks resistant to freeze-thaw cycles?

- Generally, insulating fire bricks are resistant to freeze-thaw cycles. They are designed with low thermal conductivity and high resistance to thermal shock, making them durable and able to withstand extreme temperature variations, including freeze-thaw cycles. This resistance to freeze-thaw cycles is crucial in applications where the bricks are exposed to fluctuating temperatures, like in furnaces, kilns, and other high-temperature environments. Moreover, the insulating properties of these bricks minimize heat loss and prevent moisture penetration, further improving their resistance to freeze-thaw cycles. However, it is important to note that the composition and manufacturing process of the insulating fire bricks may vary, so it is recommended to consult the manufacturer's specifications and guidelines to ensure their suitability for the intended application.

Send your message to us

Insulating Fire Brick Lightweight Fire Clay

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords