Insulating Fire Brick - Light Dense Mullite Insulation Brick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Thermal Insulation Fire Clay Brick

Refractory brick is a refractory material used in lining furnaces, kilns, fireboxes, and fireplaces.

We provide high quality Refractory Fire Bricks that are used on wide range in the various industries like Cement, Glass and Steel. Refractory Fire Bricks are provided as per the quantity and specifications required by the customers. We provide an extensive range of Refractory Fire Bricks at reasonable prices that depend upon the quantity ordered.

Application

Insulating Fire Brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment and good service

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

(4)Flexible payment: T/T L/C D/P D/A

(5)Professional marketing team and after-sale service

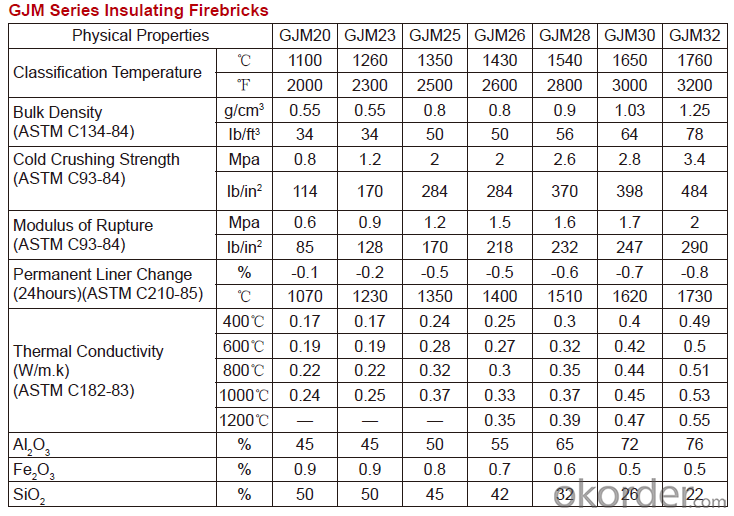

Insulating Fire Brick main feature:

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

2 units of Compact grain Abrasive pilot production lines

1 unit of high-end coated abrasives (abrasive cloth) production line

3 large flexible crushing and sieving lines for grit production lines

6 units of 5000KVA-10000KVA dumping type electric arc furnaces for Brown Fused Alumina fusion

FAQs

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Can insulating fire bricks be used in the construction of glassware production furnaces?

- Yes, insulating fire bricks can be used in the construction of glassware production furnaces. These bricks have excellent thermal insulation properties and can withstand high temperatures, making them ideal for creating a well-insulated and efficient furnace for glass production.

- Q: Can insulating fire bricks be used in metal smelting furnaces?

- Yes, insulating fire bricks can be used in metal smelting furnaces. Insulating fire bricks are designed to have low thermal conductivity, which means they can effectively retain heat and prevent heat loss from the furnace. This makes them ideal for use in metal smelting furnaces, where high temperatures need to be maintained for extended periods of time. Additionally, insulating fire bricks are resistant to thermal shock and can withstand the harsh conditions and rapid temperature changes that occur during metal smelting processes. They are also lightweight, making them easier to handle and install in the furnace. Overall, insulating fire bricks are a suitable choice for use in metal smelting furnaces to improve energy efficiency and increase the lifespan of the furnace.

- Q: Can insulating fire bricks be used in the construction of pottery ovens?

- Insulating fire bricks are suitable for the construction of pottery ovens. They possess exceptional thermal properties, including low thermal conductivity and high heat resistance. These characteristics make them perfect for insulation and heat retention in pottery ovens, facilitating efficient and controlled firing of clay and ceramic materials. Furthermore, their lightweight nature simplifies handling and installation during construction. Ultimately, incorporating insulating fire bricks in pottery ovens ensures consistent and uniform heat distribution, leading to enhanced firing results and energy efficiency.

- Q: What is the typical flexural strength of an insulating fire brick?

- The flexural strength of insulating fire bricks can vary based on the specific composition and manufacturing process. On average, these bricks have a flexural strength ranging from 2 to 10 MPa. It should be noted that individual bricks may have slightly different flexural strengths. Insulating fire bricks are utilized for thermal insulation in high-temperature situations such as furnaces, kilns, and fireplaces. Their low thermal conductivity allows them to effectively retain heat, which is crucial in environments where temperature control is important. Flexural strength refers to a material's ability to resist deformation or breakage when subjected to bending or flexing forces. The higher the flexural strength, the more resistant the material is to bending or flexing. Typically, insulating fire bricks are made from a combination of lightweight aggregates, high-temperature binders, and other additives. This composition gives them their low thermal conductivity and insulating properties, but it also impacts their mechanical strength, including the flexural strength. It's important to note that while insulating fire bricks have relatively low flexural strength compared to other refractory materials, they are not typically exposed to significant bending or flexing forces in their intended applications. Instead, their primary purpose is to provide thermal insulation, endure high temperatures, and resist thermal shock. To summarize, the flexural strength of insulating fire bricks typically ranges from 2 to 10 MPa, but this can vary based on the specific composition and manufacturing process. These bricks are primarily designed for thermal insulation rather than high mechanical strength, and their low thermal conductivity makes them suitable for a variety of high-temperature applications.

- Q: Can insulating fire bricks be used in the construction of heat storage units?

- Yes, insulating fire bricks can be used in the construction of heat storage units. These bricks are designed to have excellent thermal insulation properties, which allow them to retain and store heat effectively. Using insulating fire bricks in heat storage units helps to minimize heat loss and maintain a consistent temperature, making them suitable for applications where heat storage is required, such as in residential or commercial heating systems.

- Q: Are insulating fire bricks resistant to fire damage?

- Yes, insulating fire bricks are resistant to fire damage. They are designed to withstand high temperatures and provide excellent insulation properties, making them suitable for use in fireplaces, kilns, furnaces, and other applications that involve exposure to intense heat.

- Q: Are insulating fire bricks resistant to moisture absorption?

- Yes, insulating fire bricks are resistant to moisture absorption. These bricks are specifically designed to have low porosity, which helps to prevent the absorption of moisture. The manufacturing process involves the use of high-quality refractory materials that are able to withstand high temperatures and resist the effects of moisture. This makes insulating fire bricks an ideal choice for applications where moisture resistance is required, such as in kilns, furnaces, and other high-temperature environments.

- Q: Do insulating fire bricks have a high thermal shock resistance?

- Insulating fire bricks are commonly known for their remarkable thermal shock resistance. They are specifically engineered to endure sudden temperature variations without any fractures or damage. Crafted from lightweight refractory materials with low thermal conductivity, these bricks effectively reduce heat transfer and prevent thermal strain. Furthermore, the firing process they undergo further enhances their ability to withstand thermal shocks. In summary, these bricks are perfect for situations where extreme temperature fluctuations are encountered, making them a dependable option for insulation in high-temperature surroundings.

- Q: Is it possible to paint or coat insulating fire bricks?

- Yes, it is possible to paint or coat insulating fire bricks. However, it is important to use heat-resistant paints or coatings that can withstand high temperatures. Regular paints or coatings may not be suitable as they can crack or peel due to the intense heat. It is recommended to consult with a professional or refer to the manufacturer's guidelines to ensure the correct type of paint or coating is used for insulating fire bricks.

- Q: Can insulating fire bricks be used in paper mills?

- Yes, insulating fire bricks can be used in paper mills. Insulating fire bricks are commonly used in industrial applications, including paper mills, to provide thermal insulation and protect equipment from high temperatures. They help in maintaining optimal temperature levels and enhance energy efficiency in the paper production process.

Send your message to us

Insulating Fire Brick - Light Dense Mullite Insulation Brick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords