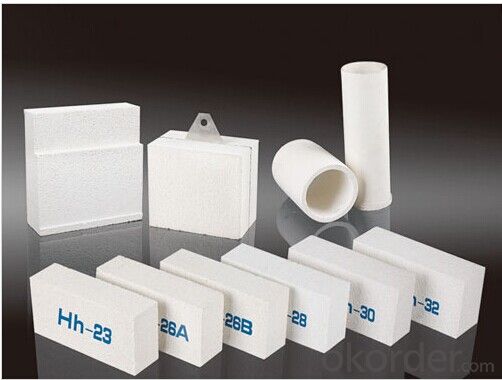

Mullite Insulating Fire Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The raw material is crude highquality highalumin low ferrous content material. The unique polylight spheres producing technique is adopted. The main structure of this high-quality heat insulation refractory brick is mullite crystal phase. The characteristics of this product are:

High compression strength

Good high-temperature performance

Excellent thermal shock stability

Low thermal conductivity

Outstanding penetration resistance ability

Erosion resistance

Application:

It may be widely used as the lining and the heat insulation layer of industrial kilns in the fields of metallurgy, petrochemistry, machinery, power, ceramics, etc... It is an ideal product of long service life, energy-saving and effects-enhancing product.

| Brand

Item |

JM-23 |

JM-26 |

JM-28 |

JM-30 |

Al2O3(%)min | 37 | 50 | 60 | 68 |

Fe2O3(%)max | 1.0 | 1.0 | 0.7 | 0.5 |

SiO2(%)max | 45 | 43 | 36 | 29 |

Safty Application Temp.(°C)max | 1260 | 1430 | 1540 | 1650 |

Bulk Density(g/cm3) | 0.5 | 0.8 | 0.95 | 1.05 |

Bending strength(Mpa)min | 0.7 | 1.1 | 1.6 | 2.0 |

Crush strength(Mpa)min | 1.0 | 2.0 | 2.3 | 2.7 |

RLC(%)max | 1230°C×24h 0.3 | 1400°C×24h 0.4 | 1510°C×24h 0.5 | 1600°C×24h 0.6 |

Reversible thermal expansion at1090°C(%) max |

0.5 |

0.6 |

0.8 |

0.8 |

Thermal conductivity (w/m.k)max 400°C 600°C 800°C 1000°C |

0.15 0.17 0.19 0.24 |

0.28 0.31 0.33 0.35 |

0.33 0.36 0.39 0.42 |

0.41 0.43 0.45 0.48 |

- Q: Can insulating fire bricks be used in power plants?

- Indeed, power plants have the capability to utilize insulating fire bricks. These bricks, also referred to as refractory bricks, are specifically designed to endure extreme temperatures and offer exceptional thermal insulation. They find extensive usage in a wide range of industrial settings, including power plants. The combustion of fossil fuels or the process of nuclear fission within power plants generates a substantial amount of heat. In order to ensure efficient operations and prevent heat loss, power plants employ insulating fire bricks to line the walls, floors, and ceilings of furnaces, boilers, and other areas that experience high temperatures. Insulating fire bricks possess a low thermal conductivity, thereby effectively reducing heat transfer. This serves to conserve energy and enhance the overall efficiency of power plants. Furthermore, these bricks exhibit high resistance to thermal shock, enabling them to withstand abrupt temperature changes without sustaining any cracks or fractures. In addition, insulating fire bricks are lightweight and simple to install, making them an ideal choice for power plant applications. They also possess resistance to chemical corrosion, which is crucial in power plants where various gases and chemicals are present. To summarize, insulating fire bricks are an appropriate option for power plants due to their ability to endure high temperatures, offer exceptional thermal insulation, and resist thermal shock and chemical corrosion. Incorporating these bricks into power plant applications serves to enhance energy efficiency and maintain optimal operating conditions.

- Q: Can insulating fire bricks be used in the construction of ceramic fiber-lined kilns?

- Indeed, the utilization of insulating fire bricks is possible for the construction of ceramic fiber-lined kilns. These specialized bricks are purposely designed to deliver exceptional insulation, rendering them ideal for situations that prioritize heat retention. By combining them with ceramic fiber lining, insulating fire bricks contribute to enhanced energy efficiency and diminished heat dissipation within kilns. Moreover, their lightweight nature and ease of handling facilitate simpler installation and construction of the kiln. Ultimately, the incorporation of insulating fire bricks in the construction of ceramic fiber-lined kilns positively impacts the kiln's overall performance and efficiency.

- Q: Is sintering insulation brick good or concrete porous brick good?

- Thermal insulation brick is functional material, it is better than porous brick in thermal insulation. At the same time, the internal heat preservation material, so the overall cost is more, the hole brick should be higher.

- Q: Can insulating fire bricks be used in reheating furnaces?

- Yes, insulating fire bricks can be used in reheating furnaces. Insulating fire bricks are designed to have excellent thermal insulation properties, which makes them ideal for use in high-temperature applications such as reheating furnaces. These bricks have low thermal conductivity, meaning they can effectively retain and reflect heat, resulting in energy savings and improved heating efficiency. Additionally, insulating fire bricks are lightweight and have good resistance to thermal shock, making them durable and suitable for the rapid temperature changes experienced in reheating furnaces. Overall, insulating fire bricks are a suitable choice for insulating and lining the walls of reheating furnaces, providing efficient heat retention and helping to maintain uniform temperatures throughout the furnace.

- Q: Can insulating fire bricks be used in the construction of heat storage systems?

- Insulating fire bricks have the potential to be utilized in the construction of heat storage systems. These bricks are specifically designed to possess low thermal conductivity, enabling them to effectively trap and retain heat. They are typically composed of materials such as fire clay, which possess exceptional insulation properties. By incorporating insulating fire bricks, it becomes feasible to minimize heat loss, thereby facilitating efficient heat storage and retention within the system. These bricks can be employed to construct the walls and lining of the heat storage system, ensuring that the stored heat does not dissipate into the surroundings. Furthermore, insulating fire bricks are lightweight and easily manageable, rendering them a convenient option for the construction of heat storage systems. Ultimately, the utilization of insulating fire bricks significantly enhances the thermal efficiency of heat storage systems, consequently contributing to more effective heat management.

- Q: Can insulating fire bricks be used for insulation in cement kilns?

- Insulation in cement kilns can be achieved by using insulating fire bricks. These bricks are made from lightweight materials like ceramic fibers or expanded clay, which possess high insulation properties. Their low thermal conductivity allows them to effectively reduce heat transfer and retain heat within the kiln. Cement kilns operate at extremely high temperatures, often surpassing 1,400 degrees Celsius (2,500 degrees Fahrenheit). Incorporating insulating fire bricks in the kiln helps prevent heat loss, enhances energy efficiency, and reduces fuel consumption. By creating a barrier between the hot gases inside the kiln and the surrounding environment, these bricks minimize heat escape. Additionally, insulating fire bricks exhibit remarkable resistance to thermal shocks, enabling them to withstand the severe temperature fluctuations that occur in cement kilns. This durability ensures long-lasting insulation, minimizing the need for frequent maintenance and replacement. Nevertheless, it is crucial to note that the specific type and composition of insulating fire bricks required for cement kiln insulation may vary depending on factors such as the kiln's design and operating conditions. Consulting with experts or manufacturers specializing in refractory materials is advisable to ensure the correct selection and installation of insulating fire bricks for cement kiln insulation.

- Q: Do insulating fire bricks require special handling?

- Yes, insulating fire bricks do require special handling. They are fragile and can easily break, so they should be handled with care to prevent any damage. It is also important to protect them from moisture as it can affect their insulating properties. Additionally, proper safety measures should be taken when working with insulating fire bricks, such as wearing protective gloves and eyewear to avoid any potential injuries.

- Q: Can insulating fire bricks be used in the construction of ceramic tile kilns?

- Yes, insulating fire bricks can be used in the construction of ceramic tile kilns. These bricks are designed to have low thermal conductivity, which helps to retain heat within the kiln. This insulation property is crucial for maintaining high temperatures and consistent firing conditions in ceramic tile kilns. Additionally, insulating fire bricks are lightweight and durable, making them suitable for kiln construction.

- Q: Can insulating fire bricks be used for insulation in heat exchangers?

- Yes, insulating fire bricks can be used for insulation in heat exchangers. Insulating fire bricks are made from a lightweight refractory material that has excellent thermal insulation properties. They have low thermal conductivity, which means they can effectively reduce heat transfer from one side of the heat exchanger to the other. This helps to maintain the desired temperature within the heat exchanger and prevents heat loss to the surroundings. Additionally, insulating fire bricks are resistant to high temperatures and can withstand thermal shocks, making them suitable for the harsh conditions often found in heat exchangers. Overall, using insulating fire bricks for insulation in heat exchangers can improve energy efficiency, reduce heat loss, and enhance the overall performance of the system.

- Q: Can insulating fire bricks be used in heat exchangers?

- Yes, insulating fire bricks can be used in heat exchangers. These bricks are designed to have excellent thermal insulation properties, making them suitable for applications where heat needs to be contained or transferred efficiently. Heat exchangers rely on the efficient transfer of thermal energy, and insulating fire bricks can help in reducing heat loss or gain in these systems, improving their overall efficiency.

Send your message to us

Mullite Insulating Fire Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords