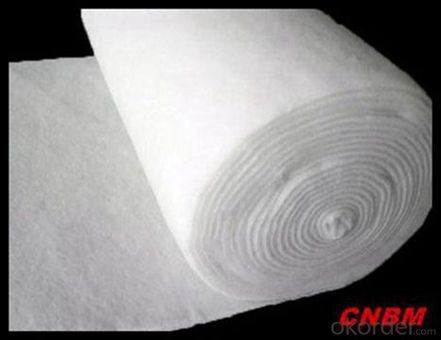

Geotextile Gsm Ilament Non-Woven Geotextile Continuous Fiber from CNBM China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Features

|

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

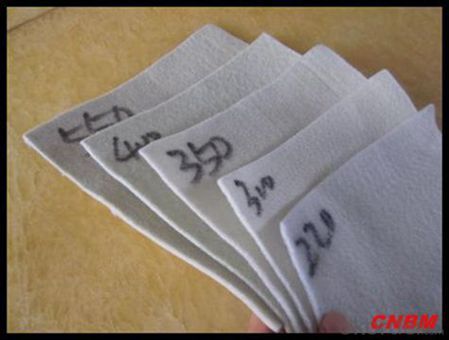

A: Yes, please check the pictures:

- Q: Production of 1 square meter 100g geotextile consumption of polyester fiber how many kilograms

- Of course, or 100 grams of Kazakhstan, the loss can be ignored manufacturers do not produce geotextile geomembrane

- Q: Can geotextiles be used in mining tailings management?

- Yes, geotextiles can be used in mining tailings management. Geotextiles are widely used in mining operations to improve the stability and containment of tailings, reduce erosion, and enhance filtration and drainage. They can be employed in various applications such as lining tailings storage facilities, constructing embankments, and creating barriers to prevent seepage. By providing reinforcement and filtration, geotextiles help in managing and mitigating the environmental impact associated with mining tailings.

- Q: Above a geotextile one, that there is any acceptance of norms?

- Geotextile with the relevant national standard, I am specializing in the production of geotechnical materials

- Q: Geotextile Model PP200-4-750 What does it mean?

- Is the geotextile 200g / ㎡? Geotextile is generally based on the weight per unit area to divide the specifications. Geotextile manufacturers Zhang Ming Chao for you to answer, I hope to help you.

- Q: Do you have a geotextile

- Summer to sunscreen, winter to antifreeze. The So summer not only to be able to block the sun, but also breathable. The Winter to warm good. The To achieve such a request, no matter what you can make the material. The

- Q: What are the advantages of using geotextiles in shoreline stabilization projects?

- Geotextiles offer several advantages in shoreline stabilization projects. Firstly, they provide effective erosion control by stabilizing soil and preventing it from being washed away by waves or currents. This helps maintain the integrity of the shoreline and prevents further erosion. Secondly, geotextiles act as a filter barrier, allowing water to pass through while trapping fine particles and preventing sedimentation. This helps maintain water quality and prevent the buildup of silt or pollutants. Additionally, geotextiles are highly durable and resistant to degradation, making them a cost-effective and long-lasting solution for shoreline stabilization.

- Q: Subgrade geotextile lap law need to suture it

- General geotextiles require stitching. Geotextile stitching must be carried out continuously. Before the overlap, the geotextile must overlap at least 150mm. The minimum seam distance from the geotextile edge is not less than 25mm.

- Q: Water stability grassroots health permeable geotextile or plastic film is good?

- 1, geotextile cloth, high unit price. 2, plastic film poor maintenance, generally do not. 3, moisturizing cotton, grass mountain child with more.

- Q: What are the specifications for geotextiles in green roof applications?

- The specifications for geotextiles in green roof applications typically include requirements for strength, permeability, UV resistance, and root resistance. These geotextiles need to be strong enough to withstand the weight of the green roof system and any potential loads, while also allowing water to drain through and preventing soil erosion. UV resistance is important to ensure the geotextile can withstand prolonged exposure to sunlight without degradation. Additionally, geotextiles used in green roofs should have root resistance properties to prevent plant roots from penetrating and damaging the underlying structure.

- Q: What are the factors to consider when specifying geotextiles?

- When specifying geotextiles, it is important to consider factors such as the type and purpose of the project, the desired functions of the geotextiles (filtration, separation, reinforcement, etc.), the site conditions, the expected loads and stresses, the required durability and longevity, the installation and maintenance requirements, and the cost-effectiveness of different geotextile options.

Send your message to us

Geotextile Gsm Ilament Non-Woven Geotextile Continuous Fiber from CNBM China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords