Hygiene White Plain Wet Wipe Use Spunlace Non-woven Fabrics

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

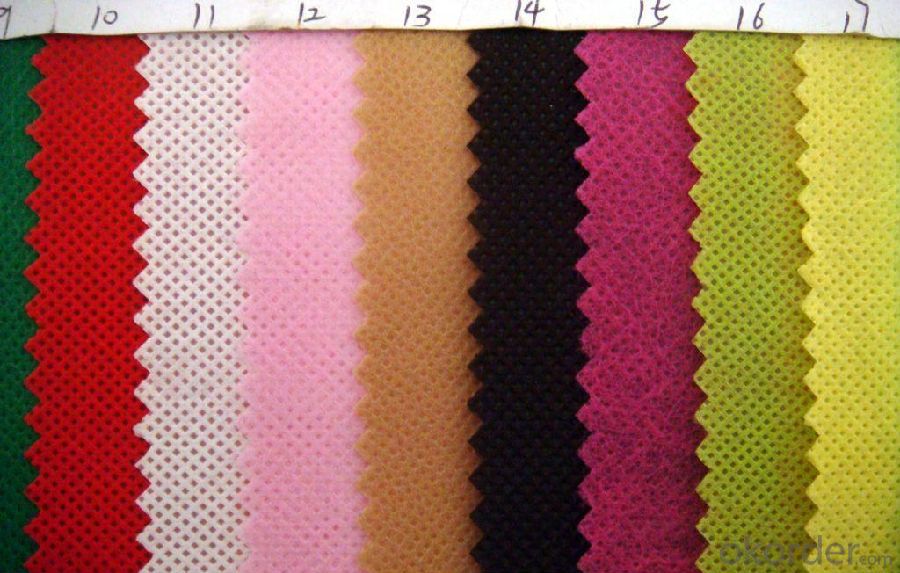

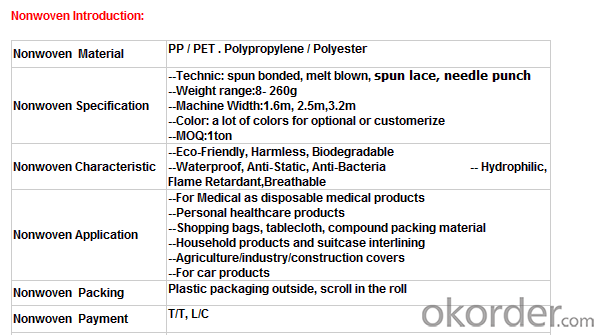

Eco-friendly Polypropylene PET Spunbond Non-woven Fabrics Made in China

Our products have been widely used in the field of medical& sanitary, industry &agriculture, and construction &daily-used products such as agriculture plant covers, roof waterproof materials, disposable items for medical and industrial applications, liners for furniture, lining in cases,apparel, warm facilities, bedding products, sofas, packing materials, packing material land mulriple cloth shopping bags, suits and garment covers, Industrial protective coveralls, garment accessory materials, bed articles, medical and sanitary articles as well.

Our Service:

Within 24 hours reply ;

Well-trained and experienced staffs in English;

OEM & ODM , Customized are warmly welcomed , or design for you ;

Protecting customer’s privacy and profits;

Make sure the quality is approved , or we pay the return or remake them at once .

Nonwoven Advantage:

1. Light: Polypropylene is the main raw material; specific gravity is 0.9, is only third five, fleecy and touches well.

2. Flexibility: made up of microfiber (2-3D), dot by dot thermo-melt formed. Flexibility of products is suitable, comfortable.

3. Water resistance and breathability: slices of Polypropylene and finished products resist water, breathable and easy to maintain and wash.

4. Non-toxic, non-irritating: made of materials which catch up FDA standard, without other chemical composition, stable, non-toxic, no smell, safe for sensitive skin.

5. Anti-bacterial, anti-chemical: Polypropylene is blunt chemical substances can protect in liquid from bacterial and insects; antibacterial, alkali corrosion, erosion and the finished product will not affect sensitive skin.

FAQ:

Q: What standards are you carrying out for your products?

A: We produce according to the ISO9001 and ISO14001 rules.

Q: How to install the machine?

A: We will arrange 1~2 engineers to your factory to guide installation and assembly.

Q: What’s your international market?

A: We Have exported to about 40 countries and regions all around the world, such as, the USA, France, Singapore, Australia, Middle East, Brazil, Peru and so on.

Q: Do you sell steel shot or steel grit which can be uses in shot blasting machine?

A: We have four production lines for steel shot and steel grit production, one work shop for steel cut wire shots, and one workshop for stainless steel shot and Aluminium shot and so on.

Q: Do you have the right to export?

A: Yes, we registered in the Customs and gained the right to export by ourselves.

- Q: Differences between textile mills and garment factories

- Hello, textile mills, including from the cotton into yarn, from the yarn woven into a fabric, while the printing and dyeing factory to fabric into fabric

- Q: What is the anti-perspiration finishing of textiles?

- Anti-perspiration finishing of textile and we often say that the perspiration fastness is completely different concept, the anti-perspiration finishing of textiles in the printing and dyeing plant on the side of the fabric side of the hydrophilic side of the waterproof processing, at the same time, the hydrophilic surface of the fabric after the hydrophilic , The corresponding waterproof surface can not see the watermark.

- Q: Classification of textile materials

- According to the definition of textile materials, the contents of textile materials, including fiber and fiber aggregates. Fibers are the basic unit of textile materials. The origin, composition, preparation, morphology, performance of the fiber is extremely rich and complex and directly affects its composition

- Q: What are the Advantages and Disadvantages of PE and PVC in Textile Fabrics

- PVC is actually a vinyl polymer, the material is a non-crystalline material. PVC materials in the actual use of often added stabilizers, lubricants, auxiliary processing agents, colorants, impact agents and other additives

- Q: The difference between double distribution and processing in textile fabrics

- Distribution - that is, you buy fabrics, only the money on the line, all of them will give you a good job.

- Q: China textile products do not how points? What kind of?

- Brand-name products, high visibility Jiangsu, Zhejiang and Shanghai textile industry on the medium and downstream products well-known, some products are Chinese famous brand, and even the world famous.

- Q: What are the policy measures developed by the Bangladeshi government for their exports?

- To help our enterprises to better understand the Bengal market, I think it is necessary for my business investment in Bangladesh textile industry for further analysis of the pros and cons, I hope this article for my textile enterprises to "go out" to provide some reference.

- Q: Clothing and processing and processing into what auxiliaries

- Textile processing used a lot of additives, spinning from the spinning machine will be used, and then to the weaving, weaving need to sizing the sizing, sizing will also use a variety of additives to increase serous duct toughness

- Q: How to grow in the textile industry and have their own customers

- First, the processing cycle of the process, which relates to your order delivery. Second, the process design, which relates to the use of your raw materials.

- Q: The international market of textile industry

- Trade protectionism is rampant and trade frictions will intensify. Leading to uncertainties in the trade environment between the trading countries. The textile faces the same mistakes as temporary tariffs and rations. China's exports will also be affected by higher production costs, financing difficulties for export enterprises and rising financing costs, export policy adjustment uncertainty, the impact of RMB appreciation pressure

Send your message to us

Hygiene White Plain Wet Wipe Use Spunlace Non-woven Fabrics

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords