Top Quality Tear-Resistant Dot Style Recycled Non Woven Fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

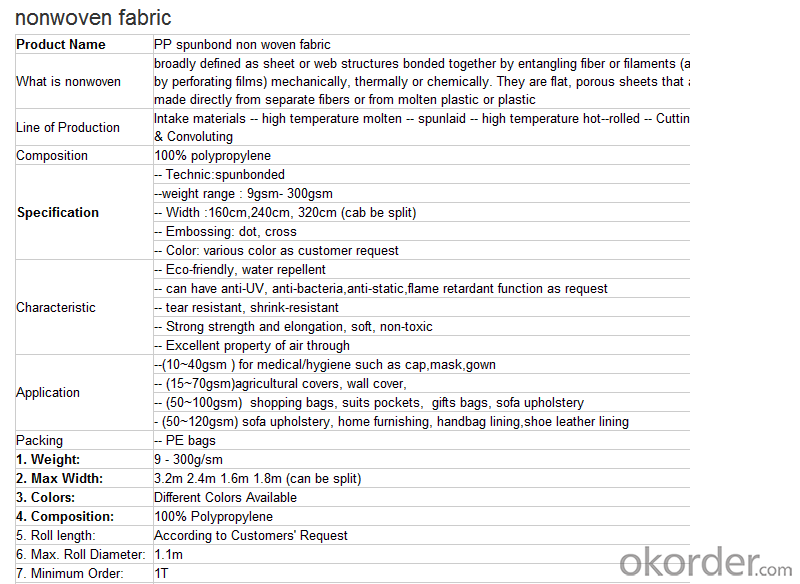

We are recognized as a reliable Manufacturer, Exporter and Supplier of Non Woven Fabric. We can provide Non Woven Fabric in any gram/m2 and any colour required by customer. Non Woven Fabrics are broadly defined as sheet or web structures bonded together by entangling fiber or filaments (and by perforating films) mechanically, thermally or chemically. PP Spun bonded Non woven Fabrics are produced using a precise extrusion-based technology. The polymer is stretched into a continuous filament and loosely spread onto a conveyor belt to form the web. Air is used to form and lay the fabric filaments. On the other hand, some non woven fabrics can be recycled after use, given the proper treatment and facilities.

Product Specifications

Weight: 10 - 150 gsm

Width: Max 1600 mm (can be slit)

Fabric Roll Length: As per buyer’s need ( 200 - 1200 Mtr)

Color: various colors available.

Procedure of production: Spun bonded Non Woven, Diamond design

Material: polypropylene

Minimum Order: 1000 Kg

Sample: sample free, freight collect

Product Application

Non woven fabric manufacturers usually manufacture the fabric in a roll form. It is then sent to various other industries where it has end applications, where is it cut and given different form depending upon the use. They can also be used in combination with different materials and offer a wide range of products.

Colored Non woven fabrics are use in many sectors and variety of applications, such as Health, Hygiene, Medical, Packaging, Agriculture, Furniture Upholstery, Geo Textiles, Leather Industry, Shoes and Garments. Customers come from the textile and automotive industries as well as many other sectors.

- Q: The weight of the textile fabric

- Fabric cost = raw material cost + weaving costs + dyeing after finishing processing fees + test volume packaging costs + tax + loss of all links

- Q: How to reduce the cost of textile yarn dyeing

- Artificial: now wage increases, the insurance state to pay, can not save

- Q: The development of wool in Australia is not developed.

- Australia is rich in natural resources, is the world's major mineral resources producer and exporter, industry to mining, manufacturing and construction-based.

- Q: What are the types of textiles that are different?

- According to the different production methods are divided into line class, with class, rope, woven fabrics, textile fabrics and other six categories:

- Q: China is now optimistic about which one of the textile industry

- Medical and industrial applications and promotion of spunbond, meltblown, spunlace and its composite non-woven "three resistance" (anti-microbial, anti-blood, anti-alcohol) surgical clothing, hole towels and other medical textiles industrial production and application ; Bionic organs and other medical textile materials and products development and application

- Q: What are the raw materials for textiles?

- You can wall wall (tapestry), not afraid of the fire and the fire (asbestos cloth, fire clothes). Like Weng woman to Tong Yan (actor dressing veil), really for the soldiers to add wings (parachute). Can protect the rocket head (aramid fiber fabric), can be used for bulletproof clothing. Enough to filter (functional fiber), where fear of electric shock (live operation taking the pressure of silk). Beauty Kam, embroidery (embroidery), odd with tapestry.

- Q: From the yarn to the finished textile fabric production process is how

- Nylon is the most important engineering plastics, production in the top five general engineering plastics in the first place. Nylon [1], is a polyamide fiber (nylon) is a saying can be made of long fiber or staple fiber. Mercerized cotton: in accordance with the two mercerizing process division, mercerized cotton can be either through the yarn mercerized process of cotton yarn processing, but also refers to the fabric after mercerized cotton fabric

- Q: "Textile color standard system"

- Because the fabric in the processing and use of the conditions encountered by the difference is very different, different requirements, so the current test methods are mostly according to the role of the environment and conditions for simulation or comprehensive test, so the color fastness test method Content is quite extensive.

- Q: What are the knowledge and abilities of the Merchants in the textile industry?

- Merchandiser, is to follow up the list of personnel, the task is: to make the list of products on time, by volume, according to quality in place. The key is "with

- Q: What is the imo standard in the textile industry?

- The Global Organic Textiles Standard (GOTS) recognizes IMO certification and produces a consistent technical standard for all major world markets for textile and garment production.

Send your message to us

Top Quality Tear-Resistant Dot Style Recycled Non Woven Fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords