100% SMS Nonwoven Fabric, Spunbond PP Non Woven Fabric, TNT Non Woven Fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

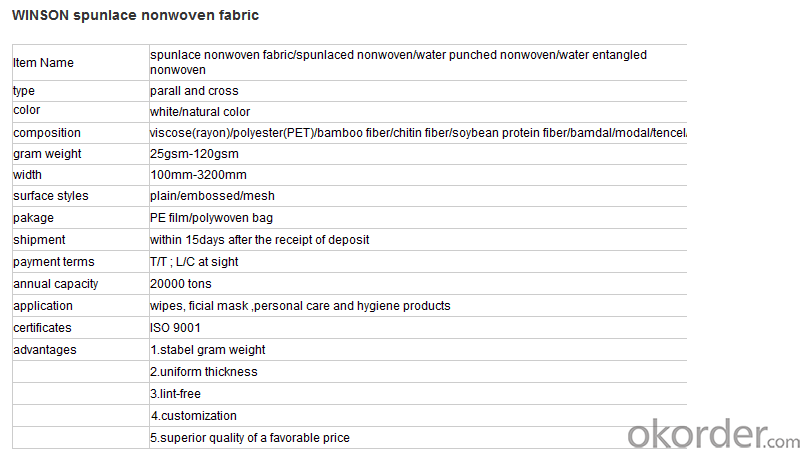

We are recognized as a reliable Manufacturer, Exporter and Supplier of Non Woven Fabric. We can provide Non Woven Fabric in any gram/m2 and any colour required by customer. Non Woven Fabrics are broadly defined as sheet or web structures bonded together by entangling fiber or filaments (and by perforating films) mechanically, thermally or chemically. PP Spun bonded Non woven Fabrics are produced using a precise extrusion-based technology. The polymer is stretched into a continuous filament and loosely spread onto a conveyor belt to form the web. Air is used to form and lay the fabric filaments. On the other hand, some non woven fabrics can be recycled after use, given the proper treatment and facilities.

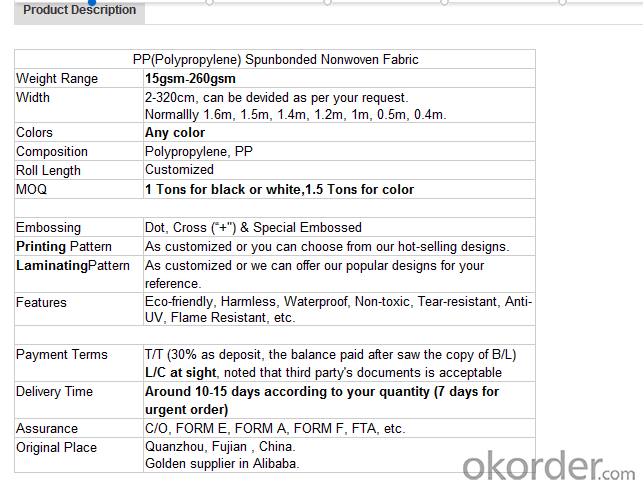

Product Specifications

Weight: 10 - 150 gsm

Width: Max 1600 mm (can be slit)

Fabric Roll Length: As per buyer’s need ( 200 - 1200 Mtr)

Color: various colors available.

Procedure of production: Spun bonded Non Woven, Diamond design

Material: polypropylene

Minimum Order: 1000 Kg

Sample: sample free, freight collect

Product Application

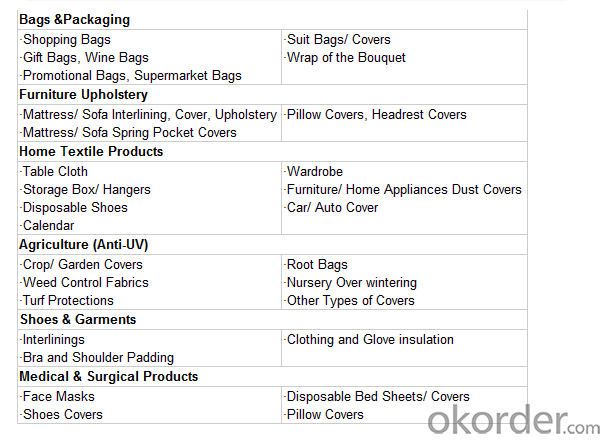

Non woven fabric manufacturers usually manufacture the fabric in a roll form. It is then sent to various other industries where it has end applications, where is it cut and given different form depending upon the use. They can also be used in combination with different materials and offer a wide range of products.

Colored Non woven fabrics are use in many sectors and variety of applications, such as Health, Hygiene, Medical, Packaging, Agriculture, Furniture Upholstery, Geo Textiles, Leather Industry, Shoes and Garments. Customers come from the textile and automotive industries as well as many other sectors.

- Q: What is the anti-perspiration finishing of textiles?

- At present, the domestic can do single-parent single-finishing manufacturers have a lot, but do not much anti-perspiration finishing manufacturers, because of its high technical requirements, many manufacturers put anti-perspiration requirements made of single-parent single fabric, from In a sense is to complete the customer's request,

- Q: Textile machine, I should use single-phase power or three-phase electricity

- Single-phase electrical civilian electricity, if away from the transformer far, easy fluctuations in the electricity network, will cause voltage instability. Therefore, you should be based on your machine installed around the power situation to determine

- Q: Are hats a class of textile and apparel products?

- All year round seems to generally only winter hat, hat should belong to the textile and apparel products bar. Jewelery is available all year round.

- Q: What is the number of raw materials for textile enterprises?

- Cost calculation According to the comprehensive cost of the slurry, and then by the sizing rate to plan the need to consume the total amount of slurry to determine the cost of another sizing energy consumption is also a great cost.

- Q: What is eco textile?

- Consumption ecology - from the perspective of human ecology, the study of the residual toxic substances in textiles on human health; 3. dealing with ecology - from the perspective of ecological treatment, control of textile recyclable, natural degradation, waste treatment Its release of toxic substances harmless to the environment.

- Q: How does the chemical composition of the textile be analyzed?

- Cotton, hemp, wool (sheep, rabbit), silk, polyester, viscose, spandex, nylon, cashmere and so on

- Q: "Textile color standard system"

- The dye molecules and heavy metal ions are likely to be absorbed by the skin and endanger the health of human skin, on the other hand will affect the other clothing worn on the body was stained, or with other clothes when washing dirty other clothing The

- Q: What is the difference between the mesh pattern on the textile structure?

- Disadvantages and polyester, like moisture and poor ventilation. Acrylic, features: polish than wool, silk fiber is good. But poor wear resistance. There are also vinylon, polypropylene, spandex and so on

- Q: What is the imo standard in the textile industry?

- But this certification for those who need more flexibility to achieve the standard brand, the market is too strict. The Global Organic Textiles Standards Working Group says that they know that not every certification can be realized immediately and that the different stages of the conversion will be defined over the next two years.

- Q: What is the use of polyurethane TPU hot melt adhesives in textiles?

- To tie on behalf of sewing can greatly reduce the labor intensity of clothing, and the production of fine clothing, fit, strong and solid. Hot melt adhesives used for fabric paste mainly polyamide, polyurethanes and polyurethane and the like.

Send your message to us

100% SMS Nonwoven Fabric, Spunbond PP Non Woven Fabric, TNT Non Woven Fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords