non woven fabric manufacturer wet wipes material spunlace

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are recognized as a reliable Manufacturer, Exporter and Supplier of Non Woven Fabric. We can provide Non Woven Fabric in any gram/m2 and any colour required by customer. Non Woven Fabrics are broadly defined as sheet or web structures bonded together by entangling fiber or filaments (and by perforating films) mechanically, thermally or chemically. PP Spun bonded Non woven Fabrics are produced using a precise extrusion-based technology. The polymer is stretched into a continuous filament and loosely spread onto a conveyor belt to form the web. Air is used to form and lay the fabric filaments. On the other hand, some non woven fabrics can be recycled after use, given the proper treatment and facilities.

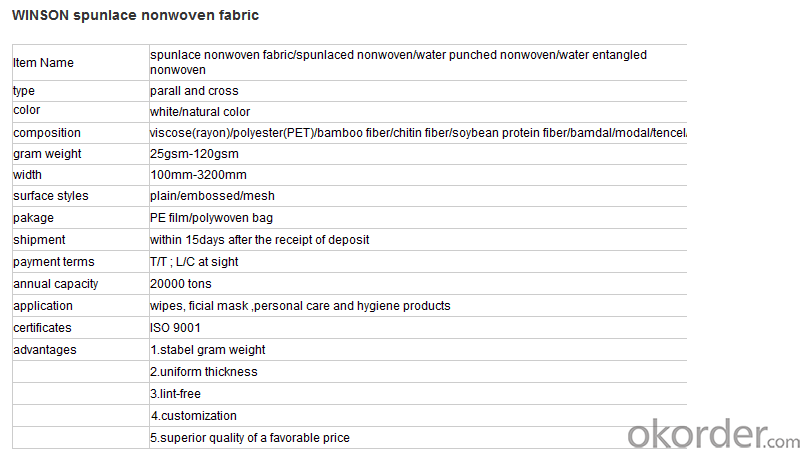

Product Specifications

Weight: 10 - 150 gsm

Width: Max 1600 mm (can be slit)

Fabric Roll Length: As per buyer’s need ( 200 - 1200 Mtr)

Color: various colors available.

Procedure of production: Spun bonded Non Woven, Diamond design

Material: polypropylene

Minimum Order: 1000 Kg

Sample: sample free, freight collect

Product Application

Non woven fabric manufacturers usually manufacture the fabric in a roll form. It is then sent to various other industries where it has end applications, where is it cut and given different form depending upon the use. They can also be used in combination with different materials and offer a wide range of products.

Colored Non woven fabrics are use in many sectors and variety of applications, such as Health, Hygiene, Medical, Packaging, Agriculture, Furniture Upholstery, Geo Textiles, Leather Industry, Shoes and Garments. Customers come from the textile and automotive industries as well as many other sectors.

- Q: What kind of fiber can be used as textile fiber

- Mainly used for textile man-made fibers are: viscose fiber, acetate fiber, copper ammonia fiber. Synthetic fiber, synthetic fiber chemical composition and natural fiber is completely different, from some of its own does not contain cellulose or protein substances such as oil, coal, natural gas, limestone or agricultural and sideline products, the first synthesis unit, and then chemical synthesis and mechanical processing The method of making fibers. Such as polyester fiber (polyester), polyamide fiber (nylon or nylon), polyvinyl alcohol fiber (vinylon), polyacrylonitrile fiber (acrylic), polypropylene fiber (polypropylene), polyvinyl chloride (polyvinyl chloride)

- Q: What is the anti-perspiration finishing of textiles?

- At present, the domestic can do single-parent single-finishing manufacturers have a lot, but do not much anti-perspiration finishing manufacturers, because of its high technical requirements, many manufacturers put anti-perspiration requirements made of single-parent single fabric, from In a sense is to complete the customer's request,

- Q: What is the meaning of TOP in the textile industry?

- TOP DYE generally refers to the Ma lin yarn, looked here like not. Look at your yarn count is filament.

- Q: What are the problems with the transformation and upgrading of the processing trade of textile enterprises?

- Especially in the second half of the international financial crisis is a great impact on the textile and garment export market. Textile enterprises are faced with unprecedented difficulties and challenges. February the State Council adopted the "textile industry restructuring and revitalization plan", the purpose is to actively respond to the current international financial crisis

- Q: Textile finishing TPU, TPEF film. What's the difference?

- Hardness range: by changing the TPU reaction components of the ratio, you can get different hardness of the product, and with the increase in hardness, the product still maintain good flexibility and wear resistance.

- Q: Is the textile processing and sales tax rate the same?

- For the general taxpayer, because the deductible input tax, the tax rate is not 17% or 13%, but far below the ratio.

- Q: How to grow in the textile industry and have their own customers

- First, the processing cycle of the process, which relates to your order delivery. Second, the process design, which relates to the use of your raw materials.

- Q: tera textile processing where to learn

- Textile-related materials are available through collection. You can in the big city of the relevant office where the NPC get the drawings and then that textile

- Q: From the yarn to the finished textile fabric production process is how

- Including aliphatic PA, fat-aromatic PA and aromatic PA. Among them, the aliphatic PA varieties, large output, widely used, the name of the monomer by the specific number of carbon atoms

- Q: Classification of cotton textiles

- According to the use can be divided into clothing with textiles, decorative textiles, industrial supplies three categories;

Send your message to us

non woven fabric manufacturer wet wipes material spunlace

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords