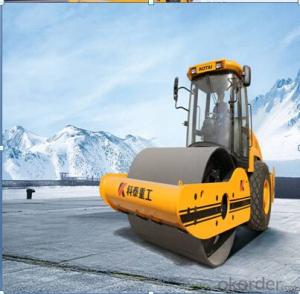

Hydraulic Double Drum Vibratory Rollers HDD630D/640

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 35 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hydraulic double drum vibratory rollers are manufactured according to international advanced technology and by use of imported main components abroad, suitable for compaction of various stabilized soils and bituminous concrete on road surface construction, which are ideal compaction equipments for industrial sites such as highway, municipal road mending, sports ground, garden lawn, etc.

MAIN FEATURES

Reliable and powerful engine of KUBOTA with large power storage, reliable performance, to reach Europe stageⅡemission standard.

Hydrostatic travel and vibration drive in both drums with greater gradeability. Higher vibration frequency with great excited force for better road surface quality.

Hydrostatic center articulated steering, infinitely variable speeds for convenient operation. The emergency stop push button assures safety and dependability of the machine.

The original imported hydraulic components as SAUER-SUNDSTRAND travel pump、POCLAIN travel motor、CENTA shaft coupling guarantees the good performance of the whole machine.

Compact design of small size and beautiful appearance, it is suited for compaction of narrow areas. Completely open engine cover offers the optimal the space of maintaining.

MAIN PERFORMANCE PARAMETERS

HDD630B | HDD640 | ||

Operating mass Static linear load Vibration amplitude Vibration frequency Centrifugal force Travel speed Gradeability Turning radius Drum width Drum diameter Wheelbase Ground clearance Diesel engine model Diesel engine power Overall dimensions | kg N/cm mm Hz kN km/h % mm mm mm mm mm

kW mm | 3000 119/112 0.45 57 30×2 9 30 5000 1300 700 1948 220 D1703 26 2650×1380×2530 | 4000 154/154 前0.7/ 后0.3 前53/ 后55 前40/后30 10 30 3400 1300 700 2093 220 D1703 26 2790×1380×2540 |

Welcome you to visit our factory in China. Anything we can do, please feel free to let us know. We are sure your inquiries will get our prompt attention.

- Q: The basic parameters of key Guiqiu YZ22G vibratory roller wheel vibration is quality, width, diameter, vibration, amplitude and frequency in YZ22GH and YZ22G have what different vibration wheel diameter and width parameters of the same? Related books have not been found on the Internet and can not find any help. Thank you

- C stands for codeIn other words, the car has undergone three improvements in A, B, and C.Some enterprises use C to represent the phonetic abbreviations of the series of serial CompactorsBut in order to have very few 20 ton double steel vibratory rollers, the possibility of C in YZ20C represents several generations of products

- Q: In the process of asphalt pavement construction, can the wheel roller use diesel oil to clean the surface of the wheel?

- If it is a metal wheel on the line, the general plastic wheel does not work, will be corroded, used up, remember to clean

- Q: Is the steel roller roller a vibratory roller?

- Tyre driven vibratory rollerWheel drive (gloriole) vibratory wheel drive lug wheel vibratory Tandem Vibratory RollerTandem type single wheel vibratory roller, tandem type double wheel vibratory roller, oscillating vibratory rollerTyre driven oscillating roller, series oscillating vibrating roller, combined vibratory rollerTire pressure vibration - nimbus combined vibration road roller oscillating combination of vibratory walking type vibration roller(single wheel) walking type vibration roller wheel walking type vibration roller towed vibratory roller (gloriole) towed vibratory towed lug wheel vibratory roller impact rollerThree side impact rollerThree side wheel impact roller, four wheel impact roller, four wheel impact roller, five side wheel impact roller, five side impact compactor, tamping machineVibratory compactorVibrating plate compactorOne-way mobile vibrating plateram two-way mobile vibratory plate compactor vibration shock ramming machine motor vibration shock ramming engine vibration shock ramming explosive ramming machine explosion ramming machine breaststroke ramming machine

- Q: The impact roller has high production efficiency

- 1. hourly compaction can be as high as 20000 square meters.2. average working speed is 10~15 kilometers per hour.

- Q: XCMG alarm lamp for vibratory roller

- Intek Advisory Network News: content tip: export ratio, roller industry before the five companies have a high degree of internationalization, but exports is relatively simple, basic to the single drumroller, accounted for 73% of export products; the mechanical single drumroller export accounted for further fell 4 percentage points. Research department statistics show that in 2013, China's Roller Road market overall situation better than last year. 2013 January, roller sales year-on-year growth momentum.

- Q: Which is more, domestic or imported rollers?,

- But the proposal was selected as the Shantui brand, quality trustworthy.

- Q: At the construction site, should the scraper, dump truck and roller be equipped with sprinkler?

- In fact, there is no absolute, but equipped with watering truck will be much easier!

- Q: Roller clutch does not move, hang not into gear, what is the problem?

- Should be the electronic control gear bar, the pressure is not enough, or power cylinder problems, clutch failure in place, the control sensor will not give the gear signal, of course, can not hang professional roller

- Q: How about roller Qingdao kotai heavy industry.

- Good, the price advantage, and other brands also have a function, but as long as it is mechanical or any other products, there are some deficiencies, it can not be perfect. If you want to use it or choose Qingdao Ketai, there are certain advantages at least economic cost

- Q: I have never touched, very strange, roller okay? By the way, under the drive must pay attention to, to the older generation back to 150Friends to learn to drive roller, I have never touched, very strange, roller okay? By the way, we must pay attention to the following road roller

- Roller but to maintain a high spirit, too high, should pay attention to whether the road ahead of soft, there may collapse, but also pay attention to pedestrians

Send your message to us

Hydraulic Double Drum Vibratory Rollers HDD630D/640

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 35 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords