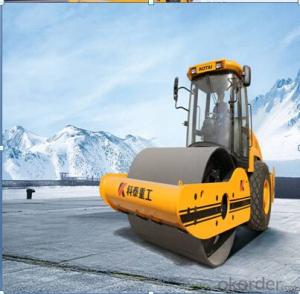

Earthmoving Machinery-Single Drum Vibratory Roller TMRC214

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 200 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Description

1. DFH water cooled trubocharged diesel engine with the cooling air-path structure and large capacity of fuel tank.

2. Heavy-duty gearbox and driving axle assure reliability and smoothness of travel transmissions.

3. Proper frequency and dual amplitude setting of vibration for various soils and variable course depth.

4. Service brake of caliper disc and parking brake of inner-extending brake greatly enhances machine safety.

5. Hinged engine hood with safety lock is wholly opened, main components as vibrating pump and braking booster are behind the engine for access to convenience of maintenance.

6. Shock and noise isolated driver cabin with the vehicle audio device ensure the operational environments more confortable.

Training Solutions – we develop our people through high impact training. We increase the connective intelligence potential of individuals and teams through practical, solution-focused programs in areas such as innovation, team collaboration, management development, strategic thinking and decision making.

2.Coaching Solutions - we increase leadership potential with performance coaching. We increase the connective intelligence potential of our managers and key contributors, assessing and developing both their cognitive and emotional intelligence's (capabilities) as the latest research, and practical experience, indicates that both are needed to drive sustained performance.

3.Reward Solutions – We reward our deserving people based on performance (we ensure equitable treatment of employees because appraisals are based on result of performance) by providing the necessary incentives. Its components can be a combination of bonuses, a range of appropriate benefits such as International trips, commissions and Stock option incentive plan for management & senior workers.

Mission & Vision: The following Core Values fulfillment is our objective.

1.Integrity and Professionalism.

2.Target and Action Oriented.

3.Service Quality & Customer Oriented.

4.Pro- Active to change.Model TMRC214-3 Operating Mass kg 14000 Static Liner Load N/cm 325 Vibration Amplitude mm 1.8/0.9 Vibration Frequency Hz 30 Centrifugal Force kN 290、160 Max. Travel Speed km/h 11 Gradeability % 35 Turning Radius mm 7000 Drum Width mm 2130 Drum diameter mm 1500 Wheelbase mm 3080 Ground Clearance mm 410 Diesel Model DFH LR6A3Z Diesel Power KW 91.2 Overall Dimensions mm 6000x2280x2995

- Q: How often do rubber tyred rollers maintain?

- 3 windshield wiper and washing check / wiper position / wear check;4. Visually inspect the outside of the body, the body under the protection of parts, pipes / hoses (exhaust - fuel lines - brake lines), rubber parts (dust cover, bushings, bushings, etc.) status;5, visual inspection of various control belt conditions;

- Q: Rules for the operation of rollers

- 1, when the operation, roller should start in order to shock, the internal combustion engine should be in the medium speed, and then modulation speed.2, speed change and reverse should be stopped first, speed change should reduce the speed of the internal combustion engine.3. No road rollers are allowed to vibrate on solid ground.4, rolling soft roadbed, should be in the case of non vibration rolling 1~2 times, and then vibration, rolling.5, rolling, vibration frequency should be consistent. Yes, you can adjust your vibratory roller, you should adjust the vibration frequency after the operation, not in case there is no vibration, adjust the vibration frequency.6. The adjustment of the reversing clutch, the shock clutch and the brake shall be carried out after the main clutch is disengaged.7, the upper and lower slopes can not use fast files. In turn, including articulated vibratory roller in small turning round rolling, prohibited the use of fast file.8. The roller shall not engage in vibration when driving at high speed.9, stop the vibration should be stopped, and then put the reverse gear in the middle position, the transmission in neutral, and finally pull hands, brake lever, the internal combustion engine idle operation after a few minutes flameout.

- Q: Strong earthquakes and small earthquakes can be used normally,

- Suddenly a weak is the connecting shaft bearing fault vibration wheel these problems in mechanical problems, there is a problem with this hydraulic system pressure test to determine the need to carefully check the problems in professional roller I ask

- Q: The road from top to bottom, followed by 500 thick gravel, 300 thick cement stabilized macadam, 100 thick asphalt. While the gravel bottom elevation and elevation is very close to the top of the rain water, how to prevent the roller crushing rain water pipes?

- There is no good way, the bottom of the 500 thick gravel can only be compacted with light rolling equipment, such as frog ram, impact rammer, etc., according to specifications above the pipe top 50 centimeters to use roller mill rolling.

- Q: How heavy is the biggest roller?

- We used the largest roller weight 33 tons, and then there is no reproduction, upgraded version is not clear

- Q: Do we have to use rubber wheels? Is there a mandatory rule?The fine-grained AC-13 is ready to let the builders use the rubber wheel, but the builders say the rubber wheel is rarely used. Would I like to know if this is necessary?

- 2. The rolling principle of the rubber wheel is different from that of the steel wheel. The rubber wheel can better improve the density3, from the perspective of engineering quality, the construction party should take all kinds of effective equipment and facilities to improve the quality of the project

- Q: What is the Jingyinshuangzi roller brainwashing and three tragedies to sing the song?

- Road roller brainwashing song, it is an ambitious Inspirational Songs Anyway, even if you know the lyrics, you don't know what you're doing...The three tragedy is the snow series. Evil series and the prisoner seriesThe snow series is for listening...

- Q: One hundred and fiftyI would like to ask all of you to tell me clearly whether the rollers need to buy strong insurance or not?I think the roller is to buy insurance, because in the "motor vehicle traffic accident liability compulsory insurance premium plan" subparagraph (a) paragraph in article sixth "special vehicles which are used in all kinds of loading oil, gas and liquid tankers; or for cleaning, cleaning, cleaning and lifting loading and unloading (excluding dump truck), a variety of special vehicle lifting, stirring, mining, bulldozing, roller etc., or for...."Please help me to find some other materials to prove that roller is to buy strong insurance, thank you!Those who have objections can also talk about it...

- According to the present law, roller belongs to a kind of construction machinery, so it can not buy strong insurance. Traffic control department will not give you a license, the driver's license is not issued by the traffic control department.

- Q: Will the Apocalypse Tank be pressurized back?

- and the apocalypse in the game setting is nuclear power driven, with nuclear reactors, has the world's most powerful armor attack with nuclear explosion effect...... roller? Go down as early as possible

- Q: What are the specific types of Compactors? What is the function of each? What is the difference?

- Here I will not say too much! Because Chinese electromechanical data network is quite comprehensive! Pure non handwritten copy and paste to forget to hope you can have a more in-depth understanding of!

Send your message to us

Earthmoving Machinery-Single Drum Vibratory Roller TMRC214

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 200 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords