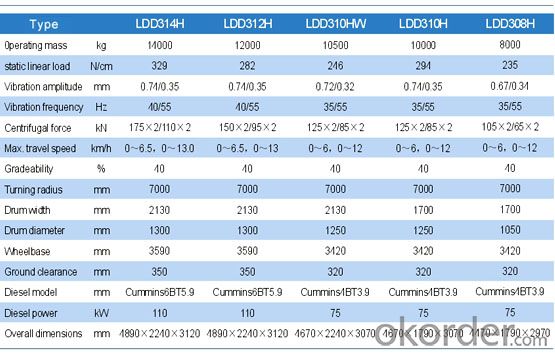

Hydraulic Double Drum Vibratory Rollers LDD314H

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 35 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hydraulic double drum vibratory rollers are manufactured according to international advanced technology and by use of imported main components abroad, suitable for compaction of various stabilized soils, bituminous concrete and rolling cement concrete (RCC) on road surface construction, also for compaction of road base course, which are universal compaction equipments for high-class highway, airport, harbors, dams, municipal road and industrial ground.

Imported COMMINS 4BTA3.9 water cooled diesel engine with rich power surplus Hydrostatic all-drum travel drive by imported hydraulic motors at two range infinitely variable speeds.

Dual frequency and amplitudes vibration system with imported piston pump and motors.

Center articulated steering with crabwalk unit for flexible maneuverability.

Integrated multi-disc wet brake with oil-cutoff braking for reliable safety.

Modernized style appearance design with inner bending side plate supports posses beautiful shape contour.

Upper surface of the drum exposed-fully, front and rear visibility may reach 1×1 meter standard for convenient observation of driver.

Driver's platform can be turned for 180 degree; All controls are ergonomically designed for light and ease operations.

Two sets of imported water pumps, large capacity water tanks and sprinkler pipes raise operational reliability.

Welcome you to visit our factory in China. Anything we can do, please feel free to let us know. We are sure your inquiries will get our prompt attention.

- Q: How many rollers are there in the roller?

- Full hydraulic pre vibration of double steel wheel.Tire type roller mill, single or full shaft.

- Q: Roller models

- According to the principle of compaction: vibration roller, static action roller, impact roller, combined rollerAt present, there are many commonly used in engineering:Single steel wheel vibratory roller (mechanical drive or full hydraulic drive): 12T/14T/16T/18T/20T/22T/26TDouble steel vibratory roller: 12T/13T/14TThree wheel static roller: 1518 / 1821 / 2124 (or 2125)Tire roller: 16T/20T/26T/30T

- Q: The difference between tracked roller and wheel roller

- Heavy duty rollers include horizontal vibratory rollers, which have their own weight plus vibration force to make the road more solid and flat, suitable for large road laying.

- Q: Where can I find someone who rents a roller? One hundredExcuse me, is there a master who rents road rollers here in Sichuan, Meishan? Or you know all you can rent a road roller. I am looking for a few roller rental information, are empty. Who can help me find a rent roller, really mad!! Thanks

- I know there is a road roller in Meishan, and he knows quite a lot of people who do road rollers, loaders and excavators. I used several rollers there, and now I have one on the construction site. The colour is good, and the labor is good.

- Q: What are the classifications of road rollers? Who can tell?,

- This is your photo paper roller, general classification mainly consists of single drum vibratory roller, rubber roller, three iron roller, double steel roller

- Q: The impact roller has high production efficiency

- 4. the thickness of each filling is 800~1200 mm.5., the project benefit is ten times of other equipments.

- Q: in order to increase the pavement permeability, the total mass of not less than 25 tons.

- As for modified asphalt mixture are generally due to discontinuous gradation, rub tire roller will make the coarse aggregate surface, causing structural depth decreases, and even bleeding. So generally use vibratory roller is better.

- Q: It is feasible to build a 2 story building. The foundation is compacted by roller

- Building foundation on the one hand is to bear the weight of the house, on the other hand, it is also necessary to ensure the uniform settlement of the house, otherwise the house will crack. No foundation, the house can not be built, there is no construction master dare to build.

- Q: What's the difference between the 1.8 ton compactor and the 3 ton flat rammer? emergency

- 1., the price is different, the last time in Hunan to build the state to buy the road lighter more expensive than flat

- Q: What are the world famous manufacturers of roller compactors?

- World rollers are well-known manufacturers mainly in Germany, Sweden, the United States and japan. The roller mechanism before several manufacturers mainly in the United States Ingersoll Rand (INGERSOLL RAND, Ingersoll Rand note: the roller's business in 2007 sold to Volvo building Volvo equipment) and Caterpillar (CATERPILLAR), Germany's BMW (BOMAG) and Wittgen (WIRTGEN), Sweden Dynapac (DYNAPAC in Japan, Sakai) (SAKAI).

Send your message to us

Hydraulic Double Drum Vibratory Rollers LDD314H

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 35 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords