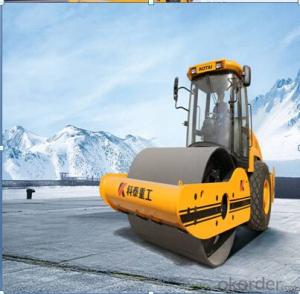

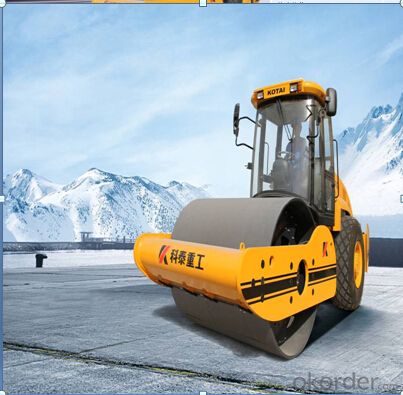

KS182S fully hydraulic single drum vibratory roller

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Main Features

SAUER driving and vibration system brings the stability and reliability.

Imported vibration bearing, “three prevention” electric plugs are of good quality

Fully hydraulic Transmission and Fully electrical-hydraulic control facilitates the operation and enhances the automation.

The walking is driven by hydraulic motor, and the monolever-controlling and CVT facilitates the operation.

Double frequency and double amplitude vibration makes sure the excellent effectiveness of compaction.

Fully-hydraulic articulated steering

Maintenance-free battery cell facilitates the maintenance.

Automatic power shutting off for braking can make sure the safety and reliability.

The stream line configuration and upturning engine housing are complined with people's aesthetic standard.

项目 Item | 单位Unit | 参数Specifications |

工作质量 Operating weight | kg | 18000 |

静线载荷 Static linear load | N/cm | 418 |

振幅 Amplitude | mm | 1.9/0.9 |

振动频率 Vibration frequency | Hz | 28/34 |

激振力 Centrifugal force | kN | 350/245 |

速度范围 Speed range | km/h | 0-9 |

爬坡能力 Gradeability | % | 40 |

转弯半径 Turning radius | mm | 6000 |

振动轮宽度 Drum width | mm | 2110 |

振动轮直径 Drum diameter | mm | 1550 |

最小离地间隙 Min. ground clearance | mm | 486 |

发动机型号 Engine model | - | DEUTZ |

功率 Rated power | kW | 125 |

燃油箱容量 Fuel tank capacity | L | 280 |

转向角 Steering angle | - | ±35° |

摇摆角 Swing angle | - | ±12° |

外型尺寸(长X宽X高) Overall dimensions (L×W×H) | mm | 6370x2310x3200 |

- Q: How much is the BMW roller 26 tons?

- BMW Dalian canal Yici engine, some structure is domestic production; there are great differences between Germany and the quality of BMW! Currently the best brand in the countryBMW rollerBMW is roller imported from Germany BMW;

- Q: How much is the rubber tyred roller?

- Tim can consult the installation of his majesty: Max technology new phonetic spelling

- Q: I would like to ask, 18T roller layered centimeters, compaction is the most appropriate?

- 18T roller is 300 cm layered and compacted most suitable

- Q: Roller cylinder is cylindrical, the width of the drum is 1.5 meters, the cross sectional diameter is 1.2 meters, if every minute to 10 laps, then 1 when the pressure of the road surface number of square meters?

- Solution: the bottom perimeter is 3.14 * 1.2=3.768 (meters)The lateral area of the cylinder is 3.768 * 1.5=5.652 (square meters)10 turns per minute, you can find one minute, the area of the road is 5.652 * 10=56.52 (square meters)1 hours =60 minutes56.52 x 60=3391.2 (square meter)Answer: 1 hours, 3391.2 square meters of road surface pressure

- Q: How many meters does this roller advance per minute? What is the area of the road that has been pressed per minute?

- 12 meters per minute, the road area under pressure is 19.2 square meters.

- Q: How many tons are the road rollers in the road? What's the model and how much is it?

- The vibration pressure is about 20.................. Prices vary, a manufacturer, a price, three rounds of pressure about two hundred thousand, vibration pressure of more than 20 to more than 30, XCMG road machine is the best, into the factory to buy, do not buy imitation, do not be cheated

- Q: What is a roller?

- The road belongs to the road equipment in construction machinery category, widely used in Embankment Compaction of highway, railway, airport runway, dam, stadium and other large projects, can crush sand, semi viscous soil, the stability of subgrade soil and asphalt concrete road surface

- Q: The second-hand roller Road on Taobao won't lie

- You mean the actual roller?Whether or not you cheat is not a problem. As long as you can apply for a refund, there will be no loss.

- Q: What is the cause of soil cracking when subgrade is pressed by subgrade?

- Subgrade is not realAskIs the soil too wet?Is the soil too wet?Chasing the answerHow many times do you press it?

- Q: I need a roller, but the search found different working principles of rollers

- Hydrostatic roller is the most common is 3 steel wheels, produced by walking the compaction effect, vibration in rolling oil single steel wheel and double steel wheel, can static pressure, but also can make the steel wheel vibration, there are two stalls, high vibration and low vibration, high Zhenneng reached more than double the compaction effect now, hydrostatic roller are eliminated for many years.

Send your message to us

KS182S fully hydraulic single drum vibratory roller

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords