Deformed Steel Rebar 14Mm Hrb400

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 190 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Deformed Steel Rebar 14Mm Hrb400

Description of Deformed Steel Rebar 14Mm Hrb400

1, Diameter: 5.5mm-10mm Deformed Steel Rebar 14Mm Hrb400

10m- 40mm Deformed Steel Rebar 14Mm Hrb400

2, Length: 6m, 9m, 12m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

Chemical Composition of Deformed Steel Rebar 14Mm Hrb400

Grade | Technical data of the original chemical composition(%) | |||||

Reinforcing steel bar HRB335 | C | Mn | Si | S | P | B |

≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | >0.0008 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 335 | ≥490 | ≥16 | ||||

Reinforcing steel bar HRB400 | C | Mn | Si | S | P | B |

≤0.25 | ≤0.16 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 400 | ≥ 570 | ≥ 14 | ||||

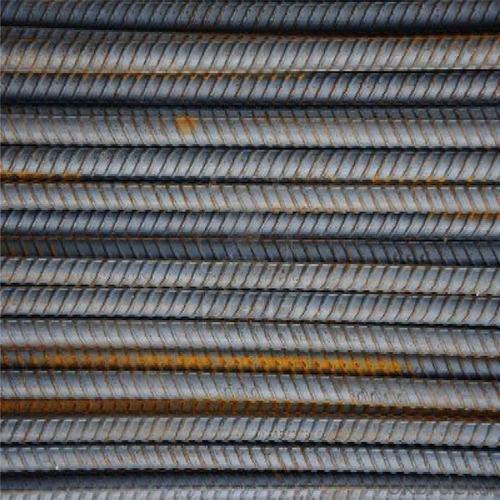

Products Show of Deformed Steel Rebar 14Mm Hrb400

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: What are the challenges in machining special steel alloys?

- Machining special steel alloys presents several challenges. These alloys are typically harder and more brittle than regular steel, making them more difficult to cut and shape. They also tend to generate higher heat during the machining process, increasing the risk of tool wear and thermal damage. Special steel alloys may also have complex microstructures and chemical compositions, which can result in uneven material removal and unpredictable machining behavior. Additionally, these alloys often have lower machinability ratings, requiring specialized cutting tools and techniques to achieve desired results. Overall, the challenges in machining special steel alloys lie in their hardness, heat generation, complex microstructures, and lower machinability, necessitating expertise and careful consideration during the machining process.

- Q: What are the main factors affecting the hardness of special steel?

- The main factors affecting the hardness of special steel include the composition of the steel, the heat treatment process, the grain size of the steel, and the presence of impurities or inclusions.

- Q: How is ultra-high-strength alloy steel used in the aerospace industry?

- Ultra-high-strength alloy steel is extensively used in the aerospace industry due to its exceptional strength-to-weight ratio. It is commonly employed in the manufacturing of aircraft components such as landing gear, engine mounts, and structural parts. This steel's remarkable strength helps enhance the overall structural integrity of aircraft, ensuring they can withstand extreme conditions and stresses encountered during flight. Additionally, its lightweight nature contributes to reducing the weight of the aircraft, which in turn improves fuel efficiency and increases payload capacity.

- Q: What are the different methods of testing the quality of special steel?

- To assess the quality of special steel, a range of testing methods are employed. These methods serve to verify that the steel meets the necessary standards and is suitable for its intended applications. One such method is chemical analysis, which involves scrutinizing the steel's composition to ensure it adheres to the required chemical specifications. This analysis helps determine the presence and quantity of crucial elements like carbon, manganese, chromium, nickel, and others, which play a significant role in achieving specific mechanical properties. Another testing approach is mechanical testing, which aims to evaluate the steel's strength, hardness, ductility, and other mechanical properties. Common tests include tensile testing, which measures the steel's ability to withstand tension, and hardness testing, which gauges its resistance to indentation or scratching. Non-destructive testing (NDT) methods are also utilized to assess steel quality without causing any damage. Techniques such as ultrasonic testing, magnetic particle testing, and liquid penetrant testing are employed to identify surface and internal defects, cracks, or discontinuities that could compromise the steel's integrity. Microscopic examination is employed to study the microstructure of special steel, allowing for the evaluation of grain size, inclusions, and other structural features. This analysis provides insights into the steel's properties and potential defects. Corrosion testing is carried out to ensure that special steel can withstand corrosive environments. Various tests, such as salt spray testing, electrochemical methods, and exposure to corrosive substances, are performed to assess the steel's resistance to corrosion and suitability for specific applications. To evaluate the steel's toughness and resistance to sudden loading, impact testing is conducted. This involves subjecting the steel to high-energy impacts to determine if it can withstand sudden shocks without fracturing. Heat treatment analysis is also essential for special steel, as it often undergoes heat treatment processes to enhance its properties. This analysis involves examining the microstructure and hardness of the steel after treatment to ensure it has achieved the desired properties. In conclusion, the combination of these testing methods guarantees that special steel meets the necessary quality standards, making it suitable for various applications in construction, automotive, aerospace, and industrial equipment.

- Q: What are the different coating techniques used for special steel?

- There are several different coating techniques used for special steel, including hot-dip galvanizing, electroplating, powder coating, and thermal spraying. Each technique has its own advantages and applications, providing enhanced protection against corrosion, improved aesthetics, or increased durability depending on the specific requirements of the steel.

- Q: How is special steel used in the production of automotive springs?

- Special steel is used in the production of automotive springs due to its high strength and durability properties, which are essential for supporting the weight of the vehicle and providing a smooth ride. The special steel's unique composition and manufacturing processes ensure that the springs can withstand repeated stress and maintain their shape over time, enhancing the overall performance and safety of the vehicle.

- Q: Can special steel be used for aerospace engine components?

- Yes, special steel can be used for aerospace engine components. Special steel alloys, such as nickel-based superalloys, are often used in the manufacturing of aerospace engine components due to their excellent high-temperature strength, corrosion resistance, and ability to withstand extreme conditions. These steel alloys are specifically designed to meet the stringent requirements and demands of aerospace applications, ensuring optimal performance and reliability of the engine components.

- Q: Can special steel be used in the production of fasteners for high-stress applications?

- Yes, special steel can be used in the production of fasteners for high-stress applications. Special steels like alloy steel or stainless steel possess enhanced strength, durability, and resistance to corrosion, making them suitable for withstanding high-stress environments. These fasteners provide reliable and secure connections even under extreme conditions, ensuring the safety and performance of the application.

- Q: How is alloy steel used in the manufacturing of gears and shafts?

- Alloy steel is commonly used in the manufacturing of gears and shafts due to its superior strength, durability, and resistance to wear and tear. Its unique properties make it ideal for withstanding high torque and heavy loads, ensuring smooth and efficient operation of gears and shafts in various industrial applications.

- Q: Can special steel be used in tool manufacturing?

- Yes, special steel can be used in tool manufacturing. Special steel refers to a category of steel that has specific properties and characteristics that make it suitable for various applications, including tool manufacturing. Special steel is often alloyed with other elements such as chromium, molybdenum, or vanadium to enhance its strength, hardness, and wear resistance. In tool manufacturing, special steel is commonly used for making cutting tools, drills, dies, molds, and other tooling components. Its high strength and hardness allow it to withstand the demanding conditions of cutting, drilling, and shaping various materials. Special steel also offers excellent resistance to wear, heat, and corrosion, making it ideal for tools that need to maintain their sharpness and performance over prolonged use. Moreover, special steel can be further processed and treated through heat treatment techniques such as quenching and tempering to achieve specific hardness levels and improve its overall performance. This versatility makes special steel a preferred choice for tool manufacturers who prioritize durability, precision, and longevity in their products. Overall, special steel has proven to be a reliable and efficient material in tool manufacturing, enabling the production of high-quality tools that meet the needs of various industries, from automotive and aerospace to construction and manufacturing.

Send your message to us

Deformed Steel Rebar 14Mm Hrb400

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 190 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords