HRB400 PC Steel Bar for Prestressed Concrete

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

HRB400 PC Steel Bar for Prestressed Concrete

Description of HRB400 PC Steel Bar

1, Diameter: 5.5mm-10mm HRB400 PC Steel Bar

10m- 40mm HRB400 PC Steel Bar

2, Length: 6m, 9m, 12m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

Chemical Composition of HRB400 PC Steel Bar

Grade | Technical data of the original chemical composition(%) | |||||

Reinforcing steel bar HRB335 | C | Mn | Si | S | P | B |

≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | >0.0008 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 335 | ≥490 | ≥16 | ||||

Reinforcing steel bar HRB400 | C | Mn | Si | S | P | B |

≤0.25 | ≤0.16 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 400 | ≥ 570 | ≥ 14 | ||||

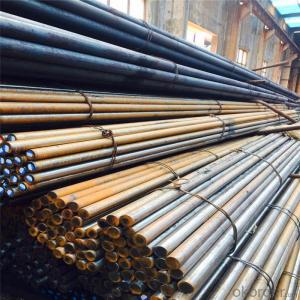

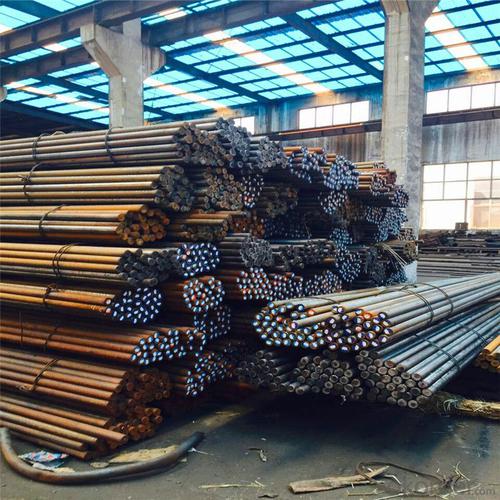

Products Show of HRB400 PC Steel Bar

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: Can special steel be used in the sporting goods manufacturing industry?

- Yes, special steel can be used in the sporting goods manufacturing industry. Special steel, with its unique properties such as high strength, durability, and corrosion resistance, can be utilized for producing various sporting goods like golf clubs, tennis rackets, bike frames, and baseball bats. These steels can enhance performance, improve longevity, and provide better control and accuracy in sports equipment.

- Q: How does special steel enhance the performance of cutting tools?

- Special steel brings about various enhancements to the performance of cutting tools. To begin with, special steel is specifically designed to possess greater hardness and wear resistance in comparison to standard steel. This heightened hardness ensures that cutting tools retain their sharpness for extended periods, resulting in improved cutting efficiency and accuracy. Furthermore, the exceptional wear resistance of special steel guarantees that the cutting edges of the tools do not wear down quickly, allowing them to endure the substantial forces and pressures involved in cutting operations. Moreover, special steel often exhibits superior toughness and strength when compared to regular steel. This augmented toughness enables cutting tools to endure impacts and vibrations without succumbing to breakage or chipping, thus ensuring their durability and longevity. Additionally, the increased strength of special steel empowers cutting tools to handle higher cutting speeds and feed rates, ultimately enhancing productivity and reducing machining time. Special steel also boasts excellent heat resistance properties, which are crucial for cutting tools subjected to elevated temperatures during machining processes. This heat resistance prevents the cutting edges from softening or deforming, circumstances that could lead to subpar cutting performance and reduced tool lifespan. Additionally, special steels can possess improved corrosion resistance, effectively shielding the tools from rust or corrosion caused by exposure to moisture or aggressive cutting fluids. In conclusion, the distinctive properties of special steel, including heightened hardness, wear resistance, toughness, strength, heat resistance, and corrosion resistance, all work together to enhance the performance of cutting tools. These characteristics enable cutting tools to maintain their sharpness, withstand high forces and temperatures, resist wear and corrosion, and ultimately improve cutting efficiency, accuracy, and tool lifespan.

- Q: What are the different methods for improving the electrical conductivity of special steel?

- There are several methods for improving the electrical conductivity of special steel, including alloying, heat treatment, and surface modifications. Alloying involves adding elements like copper, nickel, or silver to the steel to enhance its conductivity. Heat treatment processes such as annealing or quenching can also improve conductivity by altering the microstructure of the steel. Additionally, surface modifications like electroplating or coating can be employed to enhance electrical conductivity.

- Q: Can special steel be used in the production of bearings?

- Yes, special steel can be used in the production of bearings. Special steel alloys, such as chromium steel or stainless steel, are often utilized in bearing manufacturing due to their high strength, corrosion resistance, and ability to withstand heavy loads and extreme temperatures. These properties make special steel an ideal choice for ensuring the durability and performance of bearings in various industrial applications.

- Q: How does electrical steel contribute to the production of transformers and motors?

- Electrical steel, also known as silicon steel or lamination steel, plays a crucial role in the production of transformers and motors. Its unique magnetic properties make it an ideal material for the cores of these devices. The high silicon content in electrical steel reduces the energy losses that occur due to magnetic hysteresis and eddy currents, making the transformers and motors more efficient. Additionally, the laminated structure of electrical steel helps to minimize the eddy current losses further. Overall, the use of electrical steel in transformers and motors improves their performance, increases energy efficiency, and allows for compact and lightweight designs.

- Q: What is the fatigue strength of special steel?

- The fatigue strength of special steel refers to its ability to withstand repeated loading or cyclic stress without failure.

- Q: What are the different corrosion-resistant coatings for special steel?

- There are several different corrosion-resistant coatings available for special steel, each with their own unique properties and advantages. Some of the most common ones include: 1. Zinc Coating: Zinc coatings, such as galvanizing, are widely used to protect special steel from corrosion. The zinc layer acts as a sacrificial barrier, preventing the steel from coming into contact with corrosive elements. 2. Epoxy Coating: Epoxy coatings are a popular choice for corrosion protection due to their excellent adhesion, chemical resistance, and durability. They form a strong barrier that shields the special steel from moisture, chemicals, and other corrosive agents. 3. Polyurethane Coating: Polyurethane coatings provide exceptional resistance to abrasion, chemicals, and weathering. They are often used in harsh environments where the special steel is exposed to extreme conditions, such as offshore or marine applications. 4. Ceramic Coating: Ceramic coatings offer high-temperature resistance and excellent corrosion protection. They are commonly used in industries like aerospace and automotive, where the special steel needs to withstand extreme temperatures and corrosive environments. 5. Metal Coating: Metal coatings, such as nickel or chromium, are often applied to special steel to enhance its corrosion resistance. These coatings create a protective layer that prevents the steel from corroding by acting as a physical barrier. 6. Powder Coating: Powder coatings are applied electrostatically and then cured under heat, forming a hard and durable protective layer. They offer excellent corrosion resistance and can be customized in terms of color and texture. It is important to select the appropriate corrosion-resistant coating based on the specific requirements of the special steel and the environment in which it will be used. Factors such as temperature, exposure to chemicals or moisture, and the desired lifespan of the coating should all be considered when choosing the right coating.

- Q: What are the requirements for special steel used in wind turbines?

- The requirements for special steel used in wind turbines typically include high strength and durability, resistance to corrosion and fatigue, excellent weldability, and good magnetic properties. Additionally, the steel should possess good formability and machinability to aid in the manufacturing process of turbine components.

- Q: What are the key differences between special steel and tool steel?

- Special steel and tool steel are both types of steel that have specific properties and applications. However, there are some key differences between the two. 1. Composition: Special steel is a broad term that encompasses a variety of steel alloys with specific properties for different applications. It can include stainless steel, high-strength alloy steel, and heat-resistant steel, among others. On the other hand, tool steel is a specific type of special steel that is designed to be used in the production of tools, dies, and molds. Tool steel typically contains higher levels of carbon and other alloying elements like chromium, vanadium, or tungsten, which enhance its hardness, wear resistance, and toughness. 2. Hardness and wear resistance: Tool steel is known for its exceptional hardness and wear resistance, which makes it ideal for cutting, shaping, and forming materials. It can withstand high temperatures and resist deformation, ensuring the longevity of tools and dies. Special steel, on the other hand, may not have the same level of hardness and wear resistance as tool steel, as its properties vary depending on the specific alloy and application. Special steel alloys may prioritize other properties like corrosion resistance or strength. 3. Manufacturing processes: Tool steel is often produced through specialized manufacturing processes like hot working, cold working, or heat treatment to achieve the desired properties. The production of tool steel involves precise control of temperature and cooling rates to achieve the required hardness and toughness. Special steel, on the other hand, may undergo various manufacturing processes depending on the desired properties. These can include forging, casting, or heat treatment, among others. 4. Applications: Tool steel is primarily used in the production of tools, dies, and molds for manufacturing processes such as cutting, shaping, and forming materials. It is commonly used in industries like automotive, aerospace, and machinery. Special steel, on the other hand, has a wide range of applications depending on the specific alloy and properties. It can be used in industries such as construction, energy, and manufacturing, where specific properties like corrosion resistance, heat resistance, or strength are required. In summary, the key differences between special steel and tool steel lie in their composition, hardness, wear resistance, manufacturing processes, and applications. While special steel is a broad term for various steel alloys with specific properties, tool steel is a specific type of special steel designed for tooling applications. Tool steel is characterized by its exceptional hardness and wear resistance, making it ideal for cutting and shaping materials, while special steel can have a broader range of properties depending on the specific alloy and application.

- Q: What is special steel? What is special steel?

- There is no uniform definition and concept for special steel at present.It is generally believed that special steel is a kind of steel with special alloy composition, special process smelting and production, special organization and performance, and special requirement.Compared with ordinary steel, special steel has higher strength and toughness, physical properties, chemical properties, biocompatibility and process performance.

Send your message to us

HRB400 PC Steel Bar for Prestressed Concrete

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords