1/2 HPL Faced Particle Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 150 CBM m³

- Supply Capability:

- 50000 CBM per year m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Basic Date of HPL Faced Particle Board

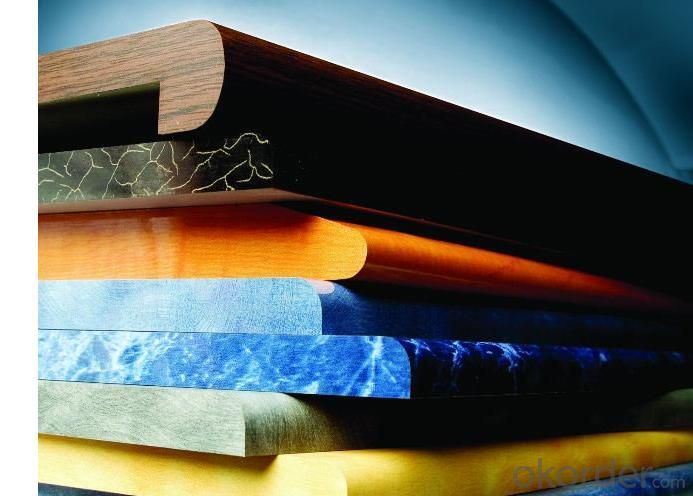

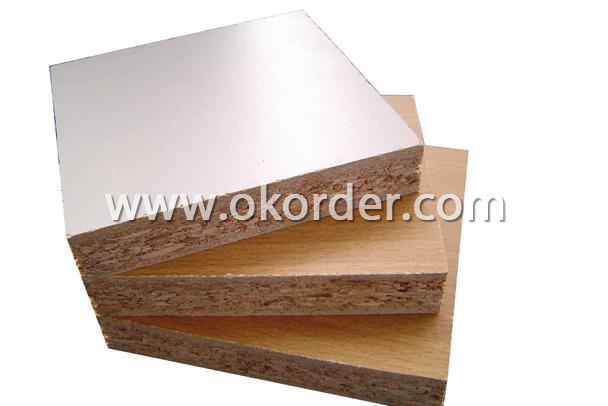

Product Name: HPL faced/laminated particle board (chipboard/flakeboard/shaving board)

Size :1220*2440

Thickness: 9-25mm

Thickness Tolerance: +/-0.2mm

Face/Back: Face is laminated with HPL (high pressure laminate board), back can be laminated with melamine paper or HPL.

2. Specification of HPL Faced Particle Board

|

Technical Parameters |

Moisture Content |

≤8% | |

|

Water Absorption |

≤10% | ||

|

Modulus of Elasticity |

≥2800Mpa | ||

|

Static Bending Strength |

≥25Mpa | ||

|

Surface Bonding Strength |

≥1.50Mpa | ||

|

Internal Bonding Strength |

≥0.80Mpa | ||

|

Screw Holding Ability |

Face |

≥1500N | |

|

Edge |

≥950N | ||

3. Usage & Performance of HPL Faced Partical Board

HPL faced partical board is widely used for table top,countertop, kitchen top, furniture,

cabinet and interio decoration. With good properties, such as, acid & alkali resistant,

heat resistant, easy fabricability, anti-static, easy cleaning, long-lasting and no seasonal effect.

- Q: Some of advantages of particleboard

- with good sound and sound insulation performance; particleboard insulation, sound absorption;

- Q: Today's demand for wood-based panel products

- which gave the development of China's particleboard industry opportunities The Therefore, China's particleboard consumption is expected to increase year by year.

- Q: According to the surface conditions:

- not the surface of the particleboard: sanding particleboard; not sanding particleboard.

- Q: A simple introduction to particleboard

- sound and sound insulation is also very good. But it also has its inherent shortcomings, because the edge of rough, easy to moisture

- Q: Particleboard industry is currently looking ahead

- so the effective utilization of forest resources and papermaking pulp waste has been paid more and more attention

- Q: What is the production process of particleboard

- it is beneficial to improve the bending strength, tensile strength and surface finish, and reduce the possibility of slag stratification in the relief.

- Q: Current Prospects for Particleboard Industry

- so great development prospects. Particleboard surface finishing processing will also appear more new materials and new technology

- Q: Particleboard by product classification

- Particleboard specifications are more, the thickness from 1.6 mm to 75 mm range, to 19 mm as the standard thickness

- Q: Market foreground and Industry development

- Particleboard due to poor quality and some other reasons, the market abandoned, many particleboard enterprises learn from the introduction of foreign advanced production lines and improve the level of technology,

- Q: The product structure of the wood-based panel industry

- and cutting and processing residues as raw materials, wood utilization rate of nearly 90% of the particleboard ratio

Send your message to us

1/2 HPL Faced Particle Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 150 CBM m³

- Supply Capability:

- 50000 CBM per year m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords