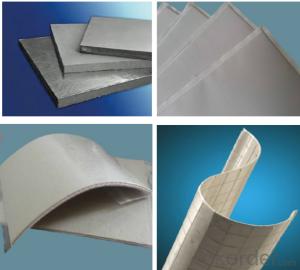

Moisture Resistant Particle Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 150 CBM m³

- Supply Capability:

- 50000 CBM per year m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Basic Sizes of Moisture Resistant Particle Board

1)Size: 1220x2440x(9~25)mm

2)Material: poplar

3)Density: 700kg/m3

4)Glue: E0, E1 or E2

2. Specification of Moisture Resistant Particle Board

|

Product Name |

Moisture resistant plain particle board/raw particle board(chipboard/flakeboard/shaving board) | ||

|

Size |

1220x2440mm or as clients requirement | ||

|

Thickness |

9~25mm | ||

|

Thickness Tolerance |

+/-0.2mm | ||

|

Surface Treatment |

Sanded or pressed | ||

|

Material |

Wood chips (poplar or combi) | ||

|

Glue |

E0, E1 or E2 | ||

|

Grade |

A grade or as clients requirement | ||

|

Density |

700~720kg/m3 | ||

|

Technical Parameters |

Moisture Content |

≤8% | |

|

Water Absorption |

≤10% | ||

|

Modulus of Elasticity |

≥2800Mpa | ||

|

Static Bending Strength |

≥25Mpa | ||

|

Surface Bonding Strength |

≥1.50Mpa | ||

|

Internal Bonding Strength |

≥0.80Mpa | ||

|

Screw Holding Ability |

Face |

≥1500N | |

|

Edge |

≥950N | ||

|

Usage & Performance |

Plain particle board is widely used for furniture and interior decoration. With good properties, such as, easy fabricability, high bending strength, strong screw holding ability, heat resistant, anti-static, long-lasting and no seasonal effect. | ||

|

Packing |

Loose packing | ||

|

Standard export pallet packing | |||

|

MOQ |

1x20’ FCL | ||

|

Supply Ability |

5000cbm/month | ||

|

Payment Terms |

T/T or L/C at sight | ||

|

Delivery Time |

Within 15 days after receiving deposit or original L/C at sight | ||

|

Certification |

ISO9001:2000, CE, CARB | ||

- Q: According to the surface conditions:

- decorative particleboard: impregnated paper finishes particleboard; decorative laminate veneer particle board; veneer veneer particleboard; surface coated particleboard; PVC veneer board and so on.

- Q: What is the modeling technology department?

- mainly urea-formaldehyde resin, the product surface with a single board or resin impregnated paper paste, a molding.

- Q: What are the raw materials for making the particleboard?

- The former fat color is light, the curing temperature is low, all kinds of plant raw materials such as wheat straw, rice husk and so on have good glue effect, hot pressing temperature is 195 ~ 210 ℃.

- Q: The environmental performance of particleboard

- The formaldehyde emission of particleboard is determined by the following method.

- Q: Make the raw material of the particleboard

- The dried shavings are then mixed with liquid gums and additives. Usually in the shavings of the surface area per square meter, sizing 8 to 12 grams

- Q: Particleboard in the production process of environmental performance

- . First of all, the unused particle board piled in a small house, close the doors and windows

- Q: What is the production process of particleboard

- The core moisture content should be appropriately lower than the surface layer to maintain proper flat tensile strength.

- Q: How does the particleboard work?

- Particleboard production method according to its slab forming and hot pressing process equipment,

- Q: Particle shape is the decisive factor in the quality of the particleboard,

- The shavings of the remainder of the woodwork can be reworked as the core of the particleboard

- Q: What are the disadvantages of particleboard?

- in the cutting board is likely to cause the phenomenon of violence teeth, so part of the process requirements for processing equipment higher; not on-site production;

Send your message to us

Moisture Resistant Particle Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 150 CBM m³

- Supply Capability:

- 50000 CBM per year m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords