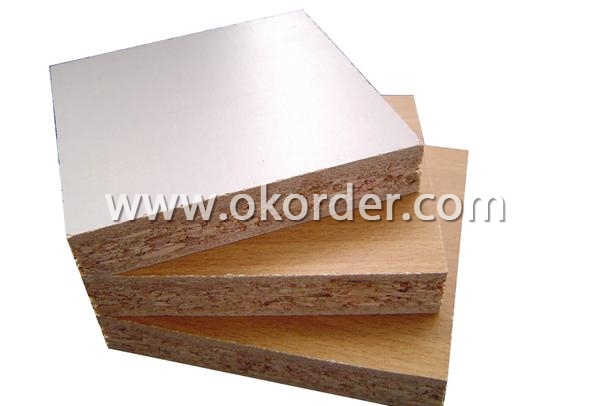

E1 Melamine Faced Particle Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 150 CBM m³

- Supply Capability:

- 50000 CBM per year m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Basic Specificaiton of Melamin Faced Partical Board

|

Plain / Poplar Particle board | |

|

Size |

1220*2440; |

|

Thickness |

2.5mm,5mm,6mm,8.0mm,9.0mm,12mm,14mm,15mm,16mm,18mm,22mm,25mm or as your request |

|

Material |

Poplar or pine |

|

Surface |

Melamine(Solid color or woodgrain),veneer,PVC |

|

Color |

Any color |

|

Glue |

E0,E1,E2,MR |

|

MOQ |

21cbm |

|

Density |

650-700kg/m3 |

|

expansion rate : |

8%-10% |

|

Features |

moisture-proof,good nailing strength,suitable for wardrobe making |

2. Products Charateristics

(1)Density:tolerance+/-2%

(2)Moisture-proff,low formaldehyde emissions,fast curing ,high tack

(3)mixed hardwood,poplar,pine or Eucalytus

(4)Good for different climatic conditions

(5)Function:making furniture,doors and windows and floor and kitchen cabinet,e.g.

(6)we have about more than 200 colors for your choice

3. Look forward to your inquiry.

We persevere in the management of credit and innovation,and we are

willing to cooperate with all the friends for mutual development. looking

forward to your inquiry and trail order.

- Q: Today's demand for wood-based panel products

- Beijing Olympic Games 280 billion yuan of investment, Shanghai World will be more than 250 billion yuan of direct investment,

- Q: According to the surface conditions:

- decorative particleboard: impregnated paper finishes particleboard; decorative laminate veneer particle board; veneer veneer particleboard; surface coated particleboard; PVC veneer board and so on.

- Q: The Particleboard quality identification editor

- including North China, northwest, northeast plate moisture content is generally controlled at 6-8% is appropriate; the southern region,

- Q: A simple introduction to particleboard

- the style of furniture better raw materials. Finished particleboard does not need to be dried again, can be used directly,

- Q: Particleboard industry is currently looking ahead

- Seeking resource-rich and inexpensive adhesives is an important factor in the development of particleboard production

- Q: Make the raw material of the particleboard

- The dried shavings are then mixed with liquid gums and additives. Usually in the shavings of the surface area per square meter, sizing 8 to 12 grams

- Q: Raw materials for the production of particleboard include

- Preparation of wood shavings processing equipment are chipper, re-crusher, grinding machine and fiber separator, cutting methods are cutting, cutting and broken.

- Q: Particleboard by product classification

- According to the arrangement of shavings in the slab, there are two kinds of directional and random type

- Q: What are the disadvantages of particleboard?

- the quality of the boardboard on the market uneven, poor quality of the poor quality of the particleboard poor formaldehyde content exceeded

- Q: The product structure of the wood-based panel industry

- China's wood-based panel industry product structure is not reasonable, difficult to adapt to market demand.

Send your message to us

E1 Melamine Faced Particle Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 150 CBM m³

- Supply Capability:

- 50000 CBM per year m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords