Particle Board 3/4 Veneer Faced Particle Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 150 CBM m³

- Supply Capability:

- 50000 CBM per year m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

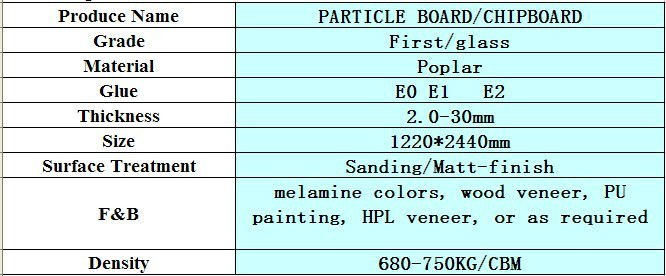

1. Description of Veneer Faced Particle Board

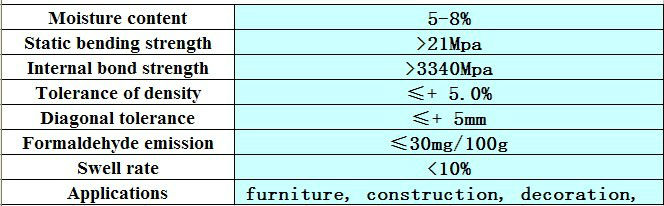

2. Technical Date of Veneer Faced Particle Board

3. Feafures of Veneer Faced Particle Board

(1)Environmental protection. Not fumigation,anti-borer , all reach environmental standards of European E1 is the

preferred health -core doors .

(2) Heat preservation. 40mm thick door by evacuation door core made of wooden doors amount to a brick wall with 300mm .

(3) Sound insulation. 40mm thick door by evacuation door-core made of wooden doors which insulation effect as high as 28db .

(4) Light in weight. Compared to the general solid wood , use tubular structures to reduce the 60% weight of the board .

4. Look forward to your inquiry

We persevere in the management of credit and innovation,and we are willing to cooperate with all the friends for mutual development.

Looking forward to your inquiry and trail order.

- Q: Particleboard industry is currently looking ahead

- and more attractive is the new technology without glue, it appears Will fundamentally change the particleboard industry.

- Q: Particleboard in the production process of environmental performance

- . First of all, the unused particle board piled in a small house, close the doors and windows

- Q: What is the production process of particleboard

- appropriate hot pressing pressure. The pressure can affect the contact area between the shavings,

- Q: Raw materials for the production of particleboard include

- In order to obtain high-quality shavings, to go through the first broken, grinding, then broken and screening process.

- Q: So for the particleboard formaldehyde release of the situation how to deal with it?

- in fact, after the decoration of the room, such as Chlorophytum, Citrus grandis,

- Q: From the appearance point of view

- look at the central part of the cross-section of the size and shape of wood particles

- Q: Particleboard production requires proper moisture content

- According to the different density requirements of products, hot pressing pressure is generally 1.2 to 1.4 MPa.

- Q: Particleboard of the unfavorable factors

- Innovation is the source of enterprise development, business is the main body of innovation activities

- Q: Particle shape is the decisive factor in the quality of the particleboard,

- Surface shavings are mainly made by cutting or processing of high-level residues (wood truncated, board edge, etc.) specially processed.

- Q: According to the use of points: Class A particleboard; Class B particleboard

- According to the particleboard structure points: single-layer structure particleboard; three-layer structure particleboard;

Send your message to us

Particle Board 3/4 Veneer Faced Particle Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 150 CBM m³

- Supply Capability:

- 50000 CBM per year m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords