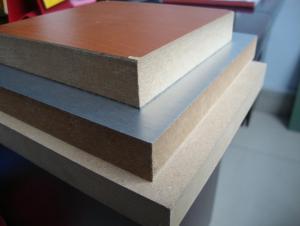

High Quality Melamine Faced Particle Board Subfloor for Furniture

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 500000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

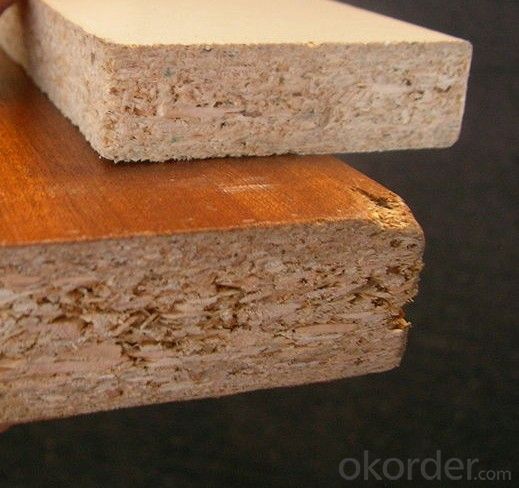

Name:particle boards

Size:1220*2440mm

Thickness:3-25mm

Glue:E0 E1 E2

Core:poplar hardwood combi

Production information

Size: | 1220*2440mm, 1250*2500mm, or as required |

Thickness | 9mm-25mm |

Gluing | E1, E2, E0 |

Material | wood chip, poplar, pine, birch, hardwood, combi |

Certifation | ISO9001,ISO1400,FSC,CE,CARB |

Moisture | 10-16% |

Diagonal tolerance | ≤+ 5mm |

Intensity | 0.35Mpa |

Formaldehyde emission | ≤30mg/100g |

Swell rate | <10%< span=""> |

Exterior structure intensity | ≥0.95Mpa |

Bending strength (kg/cm2) | 180,150 |

Density | 650-700kgs/cbm |

Payment terms | L/C at sight, T/T |

Delivery Time | within 15days after receiving deposit or original L/C |

Supply ability | 6000cbm/month |

Surface | plain or melamine, raw surface or laminated melamine paper |

Facing type | single-face, double-face |

Usage & Performance | Particle board is widely used for furniture, construction, decoration and packing |

Packing | Loose packing/ Standard export pallet packing |

Features

1) High bending strength

2) formaldehyde emission:E1 or E2

3) Strong nail holding

4) Moistureproof and easy work

5) Tight construction and high strength

FAQ

free samples are available

production time:20days after getting deposit

delivery time:30 days

payment term:T/T or L/C

- Q: According to the surface conditions:

- decorative particleboard: impregnated paper finishes particleboard; decorative laminate veneer particle board; veneer veneer particleboard; surface coated particleboard; PVC veneer board and so on.

- Q: The Particleboard quality identification editor

- the general situation is fine fine, but at some point, such as sticky fire board, too fine to bad Hanging glue.

- Q: What is the modeling technology department?

- mainly urea-formaldehyde resin, the product surface with a single board or resin impregnated paper paste, a molding.

- Q: The environmental performance of particleboard

- , when the free formaldehyde content exceeds a certain limit, it will affect human healt

- Q: Particleboard industry is currently looking ahead

- and more attractive is the new technology without glue, it appears Will fundamentally change the particleboard industry.

- Q: Raw materials for the production of particleboard include

- Therefore, the use of dryers on the initial moisture content of different shavings to dry, so that it reaches a uniform final moisture content

- Q: Current Prospects for Particleboard Industry

- As for the particleboard itself, because the directional structure in the mechanical properties significantly better than the random type structure, can be used to replace the plywood or even part of the saw plat

- Q: Market foreground and Industry development

- Particleboard due to poor quality and some other reasons, the market abandoned, many particleboard enterprises learn from the introduction of foreign advanced production lines and improve the level of technology,

- Q: Particleboard production requires proper moisture content

- appropriate pressure time. The time is too short, the middle resin can not be fully cured, the finished product in the thickness of the elastic recovery increased,

- Q: What types of particleboard can be divided into?

- the nature of the process can be machinable, can be glued, paint finish and so on

Send your message to us

High Quality Melamine Faced Particle Board Subfloor for Furniture

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 500000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords