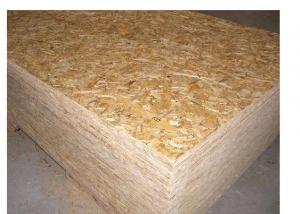

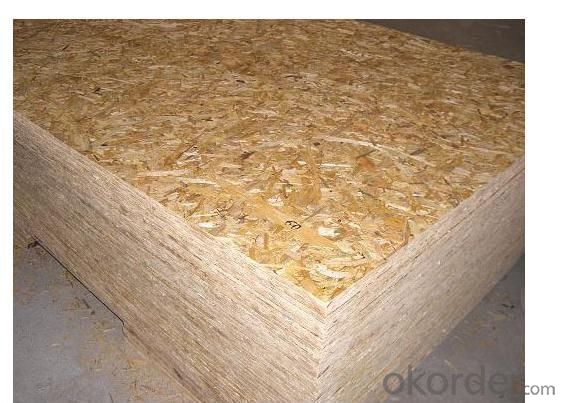

OSB2 Particle Board Sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 150 CBM m³

- Supply Capability:

- 50000 CBM per year m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Available Sizes of OSB

General Thickness: 9mm; 12mm; 15mm;25mm.Standard

Sizes: 1220*2440mm

2.Types of OSB:OSB/type-1; OSB/type-2; OSB/type-3; OSB/type-4

OSB/type-1 suits for un-loadable & general application in dry place(IndoorFurniture;Cladding).

OSB/type-2 suits for loadable application in dry places (Indoor decoration materials).

OSB/type-3 suits for loadable application in humidity places

(Wall sheathing, Roof sheathing; subflooring, structural

panel; shelving, prefabricated frame etc).

OSB/type-4 suits for heavy-loadable application in humidity places (Joist; wall and so on).

3. Specification of OSB

|

OSB/2 : Test Items |

Unit |

Performances of each thickness range | |||||

|

MM |

6-10 |

11-17 |

15-25 |

26-31 |

32-40 | ||

|

Internal bond |

Mpa |

≥0.34 |

≥0.32 |

≥0.3 |

≥0.28 |

≥0.26 | |

|

Modules of rupture |

Horizontal |

Mpa |

≥22 |

≥20 |

≥18 |

≥16 |

≥14 |

|

Vertical |

≥11 |

≥10 |

≥9 |

≥8 |

≥7 | ||

|

Modules of elasticity |

Horizontal |

Mpa |

≥3500 | ||||

|

Vertical |

|

≥1400 | |||||

|

Thickness swelling(24h) |

% |

≤20 | |||||

|

Moisture |

% |

5-12 | |||||

|

Average Density |

Kg/m3 |

650 | |||||

|

Inner Density deviation |

% |

±10 | |||||

|

Glue |

-- |

UF | |||||

|

Formaldehyde |

E1 |

Mg/100g |

≤8.0 | ||||

- Q: Some of advantages of particleboard

- particleboard in the production process, with a small amount of plastic, environmental protection coefficient is relatively high.

- Q: According to the surface conditions:

- According to the water resistance of indoor water-resistant and outdoor water-resistant class

- Q: The Particleboard quality identification editor

- including coastal areas to control between 8-10%, otherwise the plate is easy to moisture deformation.

- Q: A simple introduction to particleboard

- the style of furniture better raw materials. Finished particleboard does not need to be dried again, can be used directly,

- Q: Particleboard production process requires proper hot pressing pressure

- and then sawing sanding, inspection packaging. But after the pressure can not heat stacked, otherwise it will increase the sheet brittle.

- Q: Market foreground and Industry development

- the quality of China's particleboard has been significantly improved, and re-accepted by the market,

- Q: Particleboard production requires proper moisture content

- According to the different density requirements of products, hot pressing pressure is generally 1.2 to 1.4 MPa.

- Q: How does the particleboard work?

- Particleboard production method according to its slab forming and hot pressing process equipment,

- Q: Production of raw materials for particleboard

- Production of particleboard raw materials, including wood or wood fiber materials, adhesives and additives, the former accounted for more than 90% of the dry weight of the plate.

- Q: According to the use of points: Class A particleboard; Class B particleboard

- According to the particleboard structure points: single-layer structure particleboard; three-layer structure particleboard;

Send your message to us

OSB2 Particle Board Sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 150 CBM m³

- Supply Capability:

- 50000 CBM per year m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords