Particle Board for Shelves - Hollow Chipboard Raw and Plain Hollow Chipboard

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 400 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction: Hollow chipboard is usually used as core of Doors,and it is featured as light in weight , sound-proof anti-impact , temperature-keeping and stable in dimensions,The product reserves the virtues of wood and gets rid of its weak points such as skrinking after being wet ,and being heavy in weight,It is indeed an ideal green enwironment-friendly replacement to solid wood cores.

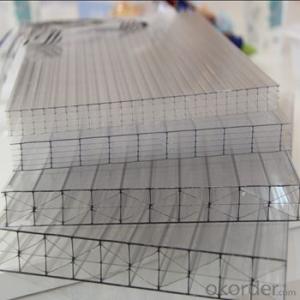

Pictures:

Product Description

1) Product Name: Plain particle board/raw particle board (chipboard/flake board/shaving board)

2) Size: 1220X2440mm or as clients requirement

3) Thickness: 9~25mm

4) Thickness Tolerance: +/-0.2mm

5) Surface Treatment: Sanded or pressed

6) Material: Wood chips (poplar or combi)

7) Glue: E0, E1 or E2

8) Grade: A Grade or as clients requirement

9) Density: 700~720kgs/cbm

10) Technical Parameters:

Moisture Content≤ 8%

Water Absorption≤ 10%

Modulus of Elasticity≥ 2800Mpa

Static Bending Strength≥ 25Mpa

Surface Bonding Strength≥ 1.50Mpa

Internal Bonding Strength≥ 0.80Mpa

Screw Holding Ability Face≥ 1500N

Edge≥ 950N

FAQ:

A: What's the main material of hollow chipboard?

B: Poplar

- Q: Some of advantages of particleboard

- particleboard surface smooth, realistic texture, uniform density, thickness error is small, resistant to pollution, anti-aging, beautiful, can be a variety of veneer;

- Q: According to the surface conditions:

- According to the slab structure of single layer, three (including multi-layer), gradient three kinds of structure.

- Q: What are the raw materials for making the particleboard?

- Widely used in the production, but the release of free formaldehyde pollution of the environment shortcomings.

- Q: Make the raw material of the particleboard

- The compound is ejected from the nozzle to form particles of 8 to 35 microns in diameter, forming an extremely thin and uniform continuous layer on the surface of the shavings

- Q: What is the production process of particleboard

- appropriate hot pressing pressure. The pressure can affect the contact area between the shavings,

- Q: Raw materials for the production of particleboard include

- Therefore, the use of dryers on the initial moisture content of different shavings to dry, so that it reaches a uniform final moisture content

- Q: So for the particleboard formaldehyde release of the situation how to deal with it?

- The most commonly used method or window ventilation, is conducive to speed up the distribution of formaldehyde,

- Q: How does the particleboard work?

- divided into intermittent production of the pressure method and the continuous production of extrusion, rolling method. The actual production to use the main pressure method.

- Q: Production of raw materials for particleboard

- Production of particleboard raw materials, including wood or wood fiber materials, adhesives and additives, the former accounted for more than 90% of the dry weight of the plate.

- Q: What types of particleboard can be divided into?

- the nature of the process can be machinable, can be glued, paint finish and so on

Send your message to us

Particle Board for Shelves - Hollow Chipboard Raw and Plain Hollow Chipboard

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 400 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords