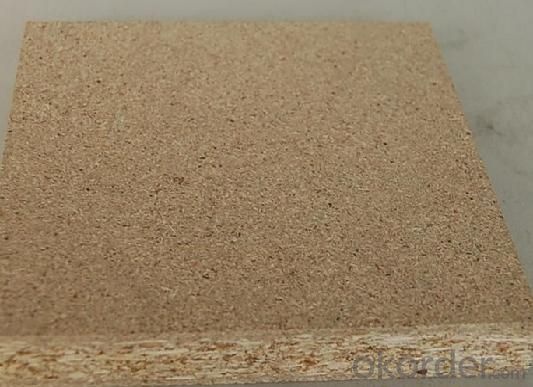

Anti-Moisture Particle Board Moisture Resistant Chipboard

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Size: 1220*2440mm/1830*3660mm and as your requirement

Core: Poplar, Hardwood, Hardwood, Combi, Birch, eucalyptus, as your requirement.

Thickness: 9mm to 25mm and as for your requirement

Application:

1) Flooring cores---Particle boards of engineering grade are suitable as the core board of variable decorative materials.

2) Counter-tops--- as core boards for counter tops

3) Particle board underlay for flooring.

4) Housing deals

5) Stair steps—PB steps have even thickness, with bull nose on side, makes installation easy and fast.

6) Shelf board

7) Door core, door frame, and shaped parts

b. water-resistant particle boards

A fixed proportion of damp-proof particle was added to the manufacture of water-resistant particle boards, thus dramatically reducing its swelling rate by contact with water. After soaked in the water for 24 hours, the swelling rate is 6%-10% only.

Major applications for water-resistant particle board:

Kitchen cabinet---- with enhanced anti-damp ability, water-resistant particle boards are perfect for making shelves, side boards, back boards, drawer, doors, etc.

Pictures:

Features

1) Environmental friendly, E1,E0,super E0 , FSC compatible

2) World-leading equipment to ensure premium quality products

3) Fine physical performance

4) Elegant color with smooth surface and pure texture, perfect for basis materials.

5) High-availability large-sheet basis.

6) Variable product for different market segments according to customer’s demands.

FAQ: A: What is your packing?

Q: Pallets(80mm) covered with plywood or carton and then steel for strength.

- Q: Some of advantages of particleboard

- particleboard in the production process, with a small amount of plastic, environmental protection coefficient is relatively high.

- Q: What are the raw materials for making the particleboard?

- The former fat color is light, the curing temperature is low, all kinds of plant raw materials such as wheat straw, rice husk and so on have good glue effect, hot pressing temperature is 195 ~ 210 ℃.

- Q: Make the raw material of the particleboard

- And then sizing the shavings after the paving slab, the thickness of the finished product is generally 10 to 20 times the thickness

- Q: What factors China's Particleboard industry development obstacles to

- product market space is still huge. In addition to ensuring the supply of raw materials and improve product quality,

- Q: Raw materials for the production of particleboard include

- The initial moisture content of the shavings is 40 ~ 60%. The water content of the core is 2 ~ 4% and the surface is 5 ~ 9%.

- Q: Current Prospects for Particleboard Industry

- and may be through the multi-species multi-functional finishes prefabricated specialization, forming an independent new industrial category

- Q: Market foreground and Industry development

- Particleboard due to poor quality and some other reasons, the market abandoned, many particleboard enterprises learn from the introduction of foreign advanced production lines and improve the level of technology,

- Q: How does the particleboard work?

- The process requirements are: ① appropriate moisture content. When the surface water content is 18 ~ 20%,

- Q: Particle shape is the decisive factor in the quality of the particleboard,

- The shavings of the remainder of the woodwork can be reworked as the core of the particleboard

- Q: What are the disadvantages of particleboard?

- in the cutting board is likely to cause the phenomenon of violence teeth, so part of the process requirements for processing equipment higher; not on-site production;

Send your message to us

Anti-Moisture Particle Board Moisture Resistant Chipboard

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m³

- Supply Capability:

- 10000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords