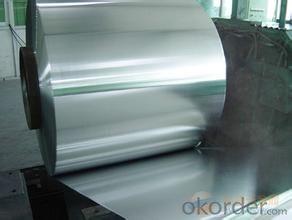

Hot Steel Coil/Sheet/Strip/Sheet Steel Coil Strip/Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Product Name | Cold Rolled Sheet Coil |

Material | SPCC/SPCD/SPCE/DC01/ST12/ ST14/SPCD/DC03/DC04 ect. |

Grade Standard | JIS G3302, EN10142, ASTM653, ASTM95 |

Thickness | 0.15-3.5mm |

Width | 600mm-1500mm |

Coil ID | 508-610mm |

Coil OD | max 1500mm |

Weight | 3-10 Tons |

Tolerance | Thickness tolerance:+/-0.02mm; Width tolerance:+/-5mm |

Surface | No-skin passed or Skin passed, Tensile leveled |

Surface Treatment | Chromate/Unchromate passivation, fingerprint resistant treatment, oiled/unoiled |

Annual Output | 350,000MT |

Application | Construction, hardware, home applicances, interior decoration |

General Application of Cold Rolled Steel Coil:

1. Refrigerators, cabinets, power distribution baords and drums.

2. Automobile floor and roof panels.

3. Automobile fenders and quarter panels

4. Automobile fenders and quarter panels

We can ensure that stable quality standards are maintained, strictly meeting both market requirements and customers’ expectations. Our products enjoy an excellent reputation and have been exported to Europe, South-America, the Middle-East, Southeast-Asia, Africa and Russia etc.. We sincerely hope to establish good and long-term business relationship with your esteemed company.

- Q: How are steel coils used in the manufacturing of automotive parts?

- Steel coils are used in the manufacturing of automotive parts by being processed and transformed into various components such as body panels, frames, suspension parts, and engine components. The coils are typically flattened, cut, and shaped according to the desired specifications before being incorporated into the assembly line to create the necessary parts for vehicles.

- Q: How are steel coils used in the production of electrical appliances?

- Steel coils are used in the production of electrical appliances as the core material for transformers and motors. The coils are wound around an iron core to create electromagnetic fields that enable efficient energy transfer and power generation within these appliances.

- Q: How are steel coils used in the production of metal staircases?

- Steel coils are an essential component in the production of metal staircases. These coils, typically made of high-quality carbon steel, are first uncoiled and then go through a series of manufacturing processes to shape them into the required stair components. The first step in the production process involves cutting the steel coils into the desired lengths using specialized machinery. This allows for customized sizing to fit the specific staircase design. Once cut, the coils are then formed into various shapes and profiles, such as stringers, treads, and risers, through processes like bending, rolling, and stamping. The use of steel coils provides several advantages in the production of metal staircases. Firstly, steel is known for its strength and durability, making it an ideal material choice for staircases that need to withstand heavy loads and frequent use. The flexibility of steel coils allows for the creation of intricate and complex staircase designs, providing architects and designers with a wide range of options. Furthermore, steel coils can be coated or finished in various ways to enhance their appearance and protect them from corrosion. This can include painting, powder coating, or applying a protective layer such as galvanization. These finishes not only add aesthetic value to the metal staircases but also increase their longevity and resistance to wear and tear. In summary, steel coils are integral to the production of metal staircases as they provide the raw material that is shaped and formed into the necessary components. Their strength, flexibility, and ability to be finished in different ways make steel coils a versatile and reliable choice for manufacturing durable and visually appealing staircases.

- Q: What are the different types of steel coil cutting machines?

- There are several different types of steel coil cutting machines available in the market, each designed to cater to specific needs and requirements. Some of the commonly used types include: 1. Slitting Machines: Slitting machines are used to cut steel coils into narrower strips. They have multiple circular blades that make precise cuts along the length of the coil, allowing for the production of narrower coils or strips. 2. Cut-to-Length Machines: Cut-to-length machines are designed to cut steel coils into specific lengths. These machines can accurately measure and cut the coil to the desired length, ensuring uniformity and precision. 3. Rotary Shears: Rotary shears are heavy-duty cutting machines that can handle thicker and larger steel coils. They use a rotating blade to cut through the coil, making it suitable for cutting thicker gauge materials. 4. Multi-Blanking Machines: Multi-blanking machines are designed to cut steel coils into multiple smaller blanks simultaneously. These machines can cut the coil into various shapes and sizes, making them ideal for producing multiple parts from a single coil. 5. Slit and Cut-to-Length Combination Machines: These machines combine the functionalities of slitting and cut-to-length machines, allowing for both narrow strip cutting and length cutting in a single process. They are versatile and efficient, saving time and increasing productivity. Each type of steel coil cutting machine has its own advantages and is suitable for specific applications. The choice of machine depends on factors such as coil thickness, desired strip width, required length accuracy, and production volume.

- Q: How are steel coils used in the manufacturing of machinery?

- Steel coils are used in the manufacturing of machinery as they serve as a primary material for various components such as gears, shafts, frames, and structural supports. These coils are typically cut, shaped, and welded to form intricate and durable parts that can withstand the demands of heavy-duty machinery. Additionally, the strength, versatility, and corrosion resistance of steel make it an ideal choice for machinery manufacturing, ensuring longevity and reliability in the final product.

- Q: What are the different types of steel coil slitting machines?

- There are several different types of steel coil slitting machines, including manual slitters, semi-automatic slitters, and fully automatic slitters. Manual slitters require manual adjustment and operation, while semi-automatic slitters have some automated features but still require some manual intervention. Fully automatic slitters are the most advanced type, with fully automated controls and high-speed operation.

- Q: Is it possible that stainless steel watches get rust. Any experience? Thanks.

- Stainless steel doesn't usually rust..... However, a lot of so-called stainless steel watch cases are actually base-metal, and does.

- Q: What are the different testing methods used for steel coils?

- There are several testing methods used for steel coils, including visual inspection, dimensional measurement, hardness testing, tensile testing, chemical analysis, and non-destructive testing techniques such as ultrasonic testing and magnetic particle inspection. These methods help ensure the quality and integrity of steel coils, allowing for accurate assessment of their mechanical properties, composition, and structural soundness.

- Q: We all know that when we drop a small steel ball (size 3mm diameter; weight 1.10 grams) and a paper (size 11.7 inches length and 8.3 inches breadth; weight 4.5 grams) from a height. The steel ball will win the race to the ground due to its aerodynamic structure.Now imagine the same steel ball with the same weight converted to the structure similar that of paper. What will be the result? Which object will fall first; steel sheet or paper?

- The 2 objects will have the same size and shape. Therefore they will have the same air resistance. So the heavier object (the sheet of paper) will reach the ground first.

- Q: Hi can someone help me pleaseis there any available data for mechanical behaviour of recycled steel, i need to compare them with new steel.

- It is not clear from the question whether the recycled steel is used in its existing state or used as raw material for further fabrication. For the existing steel, you need to track down the original documents such as the ladle analysis and mill certificates certifying the material standards for which the steel was fabricated. Another alternative is take samples and conduct chemical and mechanical tests on the steel. Also the date of when the structure was built from which the steel is recycled may help indicate whether it is (American Society for Testing and Materials) Standard ASTM A7 or ASTM A36 or another type of steel. In most cases, the steel is used as raw material to make new steel. The mill will adjust the additives to produce steel with the required chemical and physical properties to meet the ASTM standards specified.

Send your message to us

Hot Steel Coil/Sheet/Strip/Sheet Steel Coil Strip/Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords