Hot Selling Deformed Reinforcing Steel Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

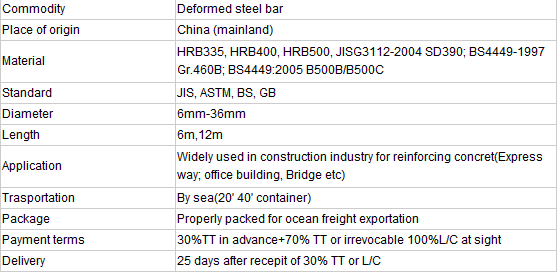

Specifications

Grade HRB335-2007 HRB400-2007 HRB500-2007

Quenched or microalloyed

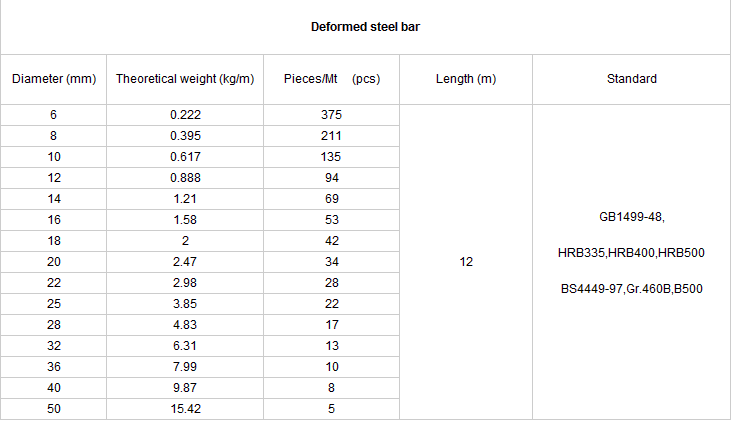

DIA 12.0mm~40.0mm deformed bar

STEEL REBARS

GB1499 Grade HRB335-2007 ( quenched or microalloyed)

GB1499 Grade HRB400-2007 (quenched or microalloyed)

GB1499 Grade HRB500-2007 ( microalloyed 20MnSiNb and 20MnSiTi)

Cutting to length: 9 or 12 1500-5000(KG) (Max.500kg/m)

Cutting to length: 6 or 7 or 8 1500-4000(KG) (Max.500kg/m)

- Q: How are steel rebars handled and transported on construction sites?

- Steel rebars are typically handled and transported on construction sites using cranes or forklifts. They are often bundled together and lifted by the crane or picked up by the forklift to be moved to the desired location. In some cases, rebars may also be transported using flatbed trucks or trailers. It is important to ensure proper lifting and secure transportation to prevent any accidents or damage during the process.

- Q: What are the common sizes of steel rebars?

- The common sizes of steel rebars vary depending on the application, but some of the most commonly used sizes include #3 (3/8 inch), #4 (1/2 inch), #5 (5/8 inch), #6 (3/4 inch), and #8 (1 inch).

- Q: What are the guidelines for spacing and positioning steel rebars in concrete structures?

- The guidelines for spacing and positioning steel rebars in concrete structures are critical to ensure the structural integrity and durability of the construction. Here are some key guidelines to follow: 1. Rebar Spacing: The spacing between steel rebars in concrete structures is determined by the structural engineer or designer. It is typically expressed in terms of center-to-center spacing or clear distance between rebars. The spacing depends on the load requirements, concrete strength, and other factors specific to the project. The most common spacing ranges from 4 to 12 inches. 2. Cover Depth: The concrete cover depth refers to the distance between the outer surface of the concrete and the nearest surface of the rebar. It is essential to provide adequate cover to protect the rebars from environmental factors, such as corrosion and fire. The cover depth is typically specified in the project's design and can vary depending on the concrete's exposure conditions. 3. Rebar Positioning: The proper positioning of rebars is crucial to ensure they are placed in the designated locations within the concrete structure. The rebars should be securely supported and maintained in the correct alignment during the concrete pouring process. The positioning requirements may include specific lap lengths, overlaps, or hooking of rebars at junctions to ensure proper load transfer and structural continuity. 4. Chair Supports: Rebar chair supports are widely used to maintain the correct spacing and elevation of the rebars within the concrete structure. These supports are placed under the rebars at regular intervals to prevent sagging or displacement during concrete placement. The appropriate chair support type and height should be selected based on the project's requirements and the diameter of the rebars. 5. Tying and Binding: Proper tying and binding of rebars are essential to ensure they remain in position and maintain the required spacing during the concrete pouring process. Rebars should be tied securely using wire or rebar ties at appropriate intervals, typically every 12-18 inches. The ties should be tight enough to prevent movement but not overly tight to avoid damaging the rebars or causing concrete segregation. 6. Concrete Consolidation: During concrete placement, it is crucial to properly consolidate the concrete around the rebars to eliminate air voids and ensure adequate bonding between the concrete and the rebars. Vibrators or other consolidation techniques should be used to achieve proper compaction and ensure the rebars are thoroughly embedded in the concrete. Compliance with the guidelines for spacing and positioning steel rebars in concrete structures is essential to guarantee the structural strength, durability, and safety of the construction. It is crucial to consult and follow the project's design specifications and engage qualified professionals to ensure proper execution and adherence to these guidelines.

- Q: What is the difference between steel rebars and FRP rebars?

- Steel rebars are traditional reinforcement bars made of steel, while FRP rebars are reinforced polymer bars. The main difference lies in their composition and properties. Steel rebars are strong and durable, but they are prone to corrosion, requiring regular maintenance. On the other hand, FRP rebars are corrosion-resistant, lightweight, and possess high tensile strength. They also offer better thermal and electrical insulation. However, FRP rebars are relatively new in the construction industry and may be more expensive compared to steel rebars.

- Q: How do steel rebars impact the overall flexibility of a structure?

- Steel rebars impact the overall flexibility of a structure by providing reinforcement and increasing its strength. The addition of steel rebars enhances the structural integrity, allowing the structure to withstand external forces and stresses without deformation or failure, thus improving its overall flexibility and durability.

- Q: What are the common challenges in handling steel rebars during construction?

- There are several common challenges in handling steel rebars during construction. One of the main challenges is the weight and size of the rebars. Steel rebars can be quite heavy and bulky, making them difficult to lift and maneuver on the construction site. This can pose a risk of injuries to the workers if proper lifting techniques and equipment are not used. Another challenge is the proper storage and organization of the rebars. Since rebars come in various lengths and sizes, it is important to have a well-organized storage area to keep them separated and easily accessible. Failure to do so can result in delays and inefficiencies during construction. Additionally, steel rebars are prone to rust and corrosion if not properly handled and stored. Exposure to moisture, rain, or even excessive humidity can cause the rebars to deteriorate, leading to weakened structures. Therefore, it is crucial to protect the rebars from these elements and store them in a dry and well-ventilated area. Furthermore, the placement and alignment of rebars within concrete structures can be challenging. It requires skilled labor and precision to ensure that rebars are correctly positioned according to the construction plans. Any errors in placement can compromise the structural integrity of the building, leading to safety concerns and costly repairs. Lastly, the transportation of rebars to the construction site can be a logistical challenge. Coordinating the delivery of rebars and ensuring they arrive on time and in the required quantities can be complex, especially in large-scale construction projects. Delays in receiving the rebars can cause project delays and additional costs. Overall, handling steel rebars during construction requires careful planning, proper storage, skilled labor, and adherence to safety protocols. By addressing these common challenges, construction projects can ensure the successful and efficient use of steel rebars.

- Q: How are steel rebars different from other types of reinforcement?

- Steel rebars, also known as reinforcing bars, are different from other types of reinforcement primarily due to their composition and strength. Unlike other types of reinforcement such as fiberglass or carbon fiber, steel rebars are made of steel, which gives them exceptional strength and durability. One of the key differences between steel rebars and other types of reinforcement is their ability to withstand high tensile forces. Steel has a high tensile strength, meaning it can resist being stretched or pulled apart. This makes steel rebars ideal for reinforcing concrete structures that are subjected to significant tensile loads, such as bridges, buildings, and highways. Another distinguishing feature of steel rebars is their ability to bond well with concrete. The ridges or deformations on the surface of rebars provide better adhesion between the steel and concrete, allowing for efficient load transfer. This bond ensures that the concrete and steel work together as a composite material, enhancing the overall strength and structural integrity of the reinforced concrete structure. Steel rebars also offer versatility in terms of shape and size. They are available in various diameters, lengths, and shapes, including round, square, and deformed. This allows engineers to choose the most appropriate type of rebar based on the specific requirements of the construction project. Additionally, steel rebars are highly resistant to corrosion, especially when they are properly coated or protected. This resistance to corrosion ensures the longevity and durability of the reinforced concrete structure, even in harsh environments or exposure to moisture. In summary, steel rebars differ from other types of reinforcement due to their exceptional strength, ability to withstand high tensile forces, excellent bond with concrete, versatility in shape and size, and resistance to corrosion. These qualities make steel rebars the most commonly used and preferred choice for reinforcing concrete structures in the construction industry.

- Q: Are there any specific safety measures to be taken while working with steel rebars?

- Yes, there are several specific safety measures to be taken while working with steel rebars. These include wearing appropriate personal protective equipment such as gloves, safety glasses, and steel-toed boots to protect against cuts, eye injuries, and foot injuries. It is also important to ensure that the work area is well-lit and free from tripping hazards. Workers should be trained in proper handling techniques to avoid strains and sprains, and should never carry or drag rebars by hand. Additionally, it is crucial to use the correct tools for cutting and bending rebars and to follow safe lifting practices to prevent back injuries. Regular inspections of the rebars for damage or defects should also be conducted to maintain a safe working environment.

- Q: How are steel rebars classified based on grades?

- The strength of steel rebars is determined by their grade, which is based on their minimum yield strength. Steel rebars are classified into different grades to indicate their ability to withstand stress and loads. Grade 40, Grade 60, and Grade 75 are the most commonly used grades for steel rebars. Grade 40 rebars have a minimum yield strength of 40,000 psi and are typically used in general construction projects where high strength is not the main requirement. They are suitable for light to moderate load-bearing structures such as residential buildings, sidewalks, and driveways. Grade 60 rebars, with a minimum yield strength of 60,000 psi, are the most widely used for construction purposes. They can be applied in a wide range of applications and are commonly used in reinforced concrete structures, bridges, highways, and commercial buildings. Grade 60 rebars provide the necessary strength to withstand heavy loads and seismic forces. Grade 75 rebars, with a minimum yield strength of 75,000 psi, are designed for high-stress applications. They are mainly used in large-scale infrastructure projects, including high-rise buildings, dams, and heavy industrial structures. Grade 75 rebars offer exceptional strength and durability, making them suitable for projects that require superior load-bearing capacity and resistance to extreme conditions. It is important to note that the specific requirements and standards for steel rebars may vary among different countries and regions. Therefore, it is crucial to adhere to local codes and regulations to determine the appropriate grade of steel rebar for each construction project.

- Q: Can steel rebars be used in structures with heavy dynamic loads?

- Yes, steel rebars can be used in structures with heavy dynamic loads. Steel rebars are commonly used in construction projects to reinforce concrete and provide additional strength and durability. They are designed to withstand various types of loads, including heavy dynamic loads caused by vibrations, impacts, or moving loads. The high tensile strength and flexibility of steel rebars make them suitable for withstanding dynamic loads and ensuring the structural integrity of the building or infrastructure.

Send your message to us

Hot Selling Deformed Reinforcing Steel Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords