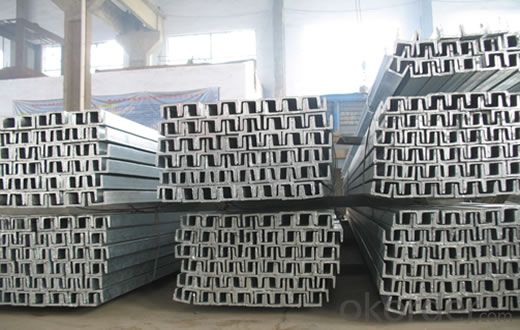

Hot rolled JIS U CHANNEL 50-300MM high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Product Description:

Specifications of MS Channel:

1.We supply high quality MS Channel at reasonable price, including Chinese standard, Japanese standard and so on.

Standard | GB/JIS |

Material Grade | Q235,SS400 |

Technique: | Hot Rolled |

Sizes as per chinese standard: | 50*37*4.5mm - 300*89*11.5mm |

Sizes as per japanese standard: | 50*25*3mm – 200*80*7.5mm |

Length: | 6meter, 9meter, 12meter |

Note: 1.we are also competent to provide our customers other MS Channel based on other sizes according to customer’s requirements.

2. The length of our ms channel could be cut into other meters as per customer’s requirements. For example, the channel in 6meters could be cut into 5.8meters in order to be fit in the 20ft container.

2. The detailed sections of MS Channel as per GB standard.are shown in the table-1:

GB U CHANNEL | Standard | Sectional | Dimension |

| Mass: |

(mm) | (mm) | (mm) | (mm) | ||

50X37 | 50 | 37 | 4.50 | 7.0 | 5.438 |

63X40 | 63 | 40 | 4.80 | 7.5 | 6.634 |

80x43 | 80 | 43 | 5.00 | 8.0 | 8.045 |

100x48 | 100 | 48 | 5.30 | 8.5 | 10.007 |

120x53 | 120 | 53 | 5.50 | 9.0 | 12.059 |

140x58 | 140 | 58 | 6.00 | 9.5 | 14.535 |

140x60 | 140 | 60 | 8.00 | 9.5 | 16.733 |

160x63 | 160 | 63 | 6.50 | 10.0 | 17.240 |

160x65 | 160 | 65 | 8.50 | 10.0 | 19.752 |

180x68 | 180 | 68 | 7.00 | 10.5 | 20.174 |

180x70 | 180 | 70 | 9.00 | 10.5 | 23.000 |

200x73 | 200 | 73 | 7.00 | 11.0 | 22.637 |

200x75 | 200 | 75 | 9.00 | 11.0 | 25.777 |

220x77 | 220 | 77 | 7.00 | 11.5 | 24.999 |

220x79 | 220 | 79 | 9.00 | 11.5 | 28.453 |

250x78 | 250 | 78 | 7.00 | 12.0 | 27.410 |

250x80 | 250 | 80 | 9.00 | 12.0 | 31.335 |

250x82 | 250 | 82 | 11.00 | 12.0 | 35.260 |

280x82 | 280 | 82 | 7.50 | 12.5 | 31.427 |

280x84 | 280 | 84 | 9.50 | 12.5 | 35.823 |

280x86 | 280 | 86 | 11.50 | 12.5 | 40.219 |

300x85 | 300 | 85 | 7.50 | 13.5 | 34.463 |

300x87 | 300 | 87 | 9.50 | 13.5 | 39.173 |

300x89 | 300 | 89 | 11.50 | 13.5 | 43.883 |

Table-1

3. The chemical composition of HR Channel Steel according to Q235B is shown in Table-2.

Alloy No | Grade | Element(%) | ||||

C | Mn | S | P | Si | ||

Q235 | B | 0.12-0.20 | 0.3-0.7 | ≦0.045 | ≦0.045 | ≦0.3 |

Table-2

Note: we are able to present our customers relevant SGS test report for chemical composition of HR Channel Steel.

4. The mechanical property of HR Channel Steel according to Q235B is shown in Table-3-1 and Table-3-2

Alloy No | Grade | Yielding Strength Point(Mpa) | |||

Thickness(mm) | |||||

≦16 | >16-40 | >40-60 | >60-100 | ||

≧ | |||||

Q235 | B | 235 | 225 | 215 | 205 |

Table-3-1

Alloy No | Grade | Tensile Strength(Mpa) | Elongation After Fracture(%) | |||

Thickness(mm) | ||||||

≦16 | >16-40 | >40-60 | >60-100 | |||

≧ | ||||||

G235 | B | 375-500 | 26 | 25 | 24 | 23 |

Table-3-2

Note: we are able to present our customers relevant SGS test report for mechanical property of MS Channel as customer’s request.

Applications of MS Channel:

The MS Channel can be applied to construction of warehouses, workshops, sport stadiums and car parks etc.The hot rolled channel steel belongs to carbon structural steel which is applied to in the field of construction and machinery.In details, the hot rolled channel steel is usually used for arch-itechtural structure, and they could be welded in order to support or hang a vari-ety of facilities. They are also usually used in combination with I beam. Generally,the hot rolled channel steel we supply must possess perfect welding property, riveting property and mechanical property and so on.

Package & Delivery of MS Channel:

1.The hot rolled channel steel will be packed in bundle with steel wire at each end of every bundle and color marking in order to help the customer to recognize his goods more easily at sight.

2. And the hot rolled channel steel could be loaded into 20ft or 40ft container, or by bulk cargo.If the weight of each bundle reaches more than 3.5 mt, the loading by break bulk cargo should be choosed.When the weight of each bundle reaches less than 3mt, the loading by container should be choosed.

3.As for the transportaion from mill to loading port, the truck will be usually used. And the maximum quantity for each truck is 40mt.

4.All in all, we could do in accordance with customer's request

- Q: Is outside building protection single row bent with cantilever steel instead of channel steel?

- Construction of single door rack erection of cantilever I-beam steel can not be used instead of steel, because the provisions of article 6.10.2 JGJ130-2011 "construction of steel tubular scaffold safety technical specifications" cantilever beam application of biaxial symmetry,...... steel beams shall not be less than 160mm. Therefore, the channel shall not be used, the cross section is asymmetrical, and the cantilever bent, the cross section is more likely to be unstable.

- Q: Can steel channels be used for HVAC ductwork?

- Steel channels are indeed suitable for HVAC ductwork. In construction, they are widely favored for their robustness and longevity. Once correctly installed and sealed, steel channels prove to be highly efficient in distributing air within a building, serving the purpose of heating, ventilation, and air conditioning. Furthermore, they can be tailored to accommodate specific ductwork designs and are applicable to both residential and commercial settings. Notably, steel channels offer a fire-resistant alternative for HVAC ductwork, rendering them highly sought-after in numerous structures.

- Q: What are the different methods for anchoring steel channels to a foundation?

- There are several different methods for anchoring steel channels to a foundation, depending on the specific requirements and load capacity of the structure. Some of the commonly used methods include: 1. Anchor Bolts: This is one of the most common methods used for anchoring steel channels to a foundation. It involves drilling holes into the foundation and inserting anchor bolts, which are then tightened using nuts and washers. These bolts provide a strong connection between the channel and the foundation. 2. Chemical Anchoring: In cases where drilling into the foundation is not feasible or desirable, chemical anchoring can be used. This method involves using epoxy resin or adhesive to bond the steel channel to the foundation. The adhesive is applied to the base of the channel, which is then pressed onto the foundation surface. Once cured, the adhesive provides a strong bond between the channel and the foundation. 3. Welding: Welding is another method used for anchoring steel channels to a foundation. This method involves welding the base of the channel directly to the foundation surface. It provides a permanent and strong connection, but requires skilled welders and may not be suitable for all applications. 4. Expansion Anchors: Expansion anchors are used when a temporary or removable connection is required. These anchors consist of a bolt or screw that is inserted into a pre-drilled hole in the foundation. As the bolt is tightened, it expands and wedges itself against the sides of the hole, providing a secure connection. 5. Concrete Embedment: In some cases, steel channels can be embedded directly into the concrete foundation. This method involves pouring the concrete around the channel, allowing it to fully surround and encase the steel. The concrete then hardens, providing a solid and permanent connection. It is important to consider factors such as load capacity, environmental conditions, and the specific requirements of the project when choosing the appropriate method for anchoring steel channels to a foundation. Consulting with a structural engineer or construction professional is recommended to ensure the proper selection and installation of the anchoring method.

- Q: What are the advantages of using steel channels over other materials?

- One advantage of using steel channels over other materials is their strength and durability. Steel channels have a high tensile strength, allowing them to withstand heavy loads and resist bending or warping. Additionally, steel is highly resistant to corrosion, making it suitable for outdoor applications or in environments with high moisture levels. Another advantage is the versatility of steel channels, as they can be easily fabricated and shaped to meet specific design requirements. Furthermore, steel is a sustainable material that can be recycled, reducing the environmental impact.

- Q: Are steel channels suitable for use in the construction of scaffolding systems?

- Yes, steel channels are suitable for use in the construction of scaffolding systems. Steel channels are known for their strength and durability, making them ideal for supporting heavy loads in scaffolding structures. They are often used as horizontal or vertical beams to provide stability and support to the scaffolding system. Steel channels also have high resistance to corrosion, which is essential for outdoor construction sites where the scaffolding may be exposed to various weather conditions. Additionally, steel channels can be easily fabricated and assembled, allowing for flexibility and customization in designing scaffolding systems to meet specific construction requirements. Overall, steel channels offer the necessary strength, durability, and versatility required for scaffolding systems, making them a suitable choice for construction projects.

- Q: 12# how much is a channel steel? The length is 6 meters. GB steel channel should be used

- The finished channel steel is delivered by hot forming, normalizing or hot rolling. The specifications are expressed in millimeters of height (H) * leg width (b) * waist thickness (d), such as 100*48*5.3, which means waist height is 100 mm, leg width is 48 mm, waist thickness is 5.3 mm channel, or 10# channel steel.

- Q: Channel 20A? What's the matter?

- Not 20A. It should be 20A. The letters in the back of the numbers are different in meaning. The letters behind the channel must be lowercase (waist thickness is different).20 represents section height 200mm of channel steel, 200*73*7.0 theoretical weight 22.637

- Q: What are the different finishing techniques for steel channels?

- Some different finishing techniques for steel channels include hot-dip galvanizing, powder coating, painting, and electroplating.

- Q: Can steel channels be used for supporting HVAC systems?

- Indeed, the utilization of steel channels for the support of HVAC systems is feasible. These steel channels are typically constructed from robust and resilient steel materials, rendering them suitable for furnishing structural support to HVAC equipment. They are frequently employed in conjunction with other supporting materials, such as brackets and hangers, in order to firmly hold and suspend HVAC units, ductwork, and piping. Steel channels offer numerous advantages when it comes to supporting HVAC systems. Primarily, they possess a substantial load-bearing capacity, guaranteeing adequate support for the weight of HVAC equipment and components. Additionally, steel channels are resistant to corrosion and can endure harsh environmental conditions, making them suitable for both indoor and outdoor applications. Moreover, steel channels provide flexibility in terms of installation. They can be effortlessly adjusted and tailored to accommodate various configurations of HVAC systems. Furthermore, steel channels can be installed using a variety of methods, including welding, bolting, or clamping, thereby offering versatility during the installation process. It is of utmost importance to ensure that the steel channels used for supporting HVAC systems are designed and installed in accordance with industry standards and local building codes. Proper engineering and design considerations, such as load calculations, seismic requirements, and thermal expansion, must be taken into account to ensure the safety and stability of the HVAC system. In summary, steel channels are a dependable and commonly employed means of supporting HVAC systems, providing strength, durability, and flexibility in installation.

- Q: What are the different cross-sectional shapes of steel channels?

- Some of the different cross-sectional shapes of steel channels include C-shapes, U-shapes, and Z-shapes.

Send your message to us

Hot rolled JIS U CHANNEL 50-300MM high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords