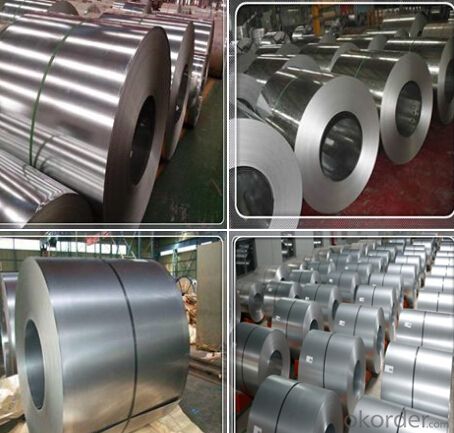

Hot Sale Grade of Stainless Steel Coil for Constructions

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic description.

Surface Treatment:2b/Ba/Polish/No.4/8k

Certification:ISO, SGS

Technique:Cold Rolled

Standard:ASTM, AISI

Application:Industrial and House

Edge:Mill

Stock:Not Stock

Steel Grade:201/202/301/304/410/430/409

Raw Material:Bao Steel/Wuhang/Tisco

Width:20-1230mm

Thickness:0.2-2.5mm

Grade:201/202/301/304

Finish:2b/Ba/Polish/8k/6k

Export Markets:Global

Product Description

1. 15 days delivery

2. deep drawing quality

3. High strength

4. Minimal maintenance

5.Technique: Cold rolled

6.Surface treatment: 2B/BA/NO.4/POLISH/8K

7.coil Thickness: 0.22-2.50mm /circle thickness:0.24-0.8mm

8.coil Width: 20-1240mm/ circle diameter:145-560mm

9.Length: To be requirement

10.Edge: Slit edge / mill edge

11.Payment: TT or L/C

12.Packaging Detail: Standard export packing

Note: We can produce for you according to your specification. We can produce other standard as the customers' requirement,

Product advantage:

1. High extensibility, easily welded, hard to rust, the best choice for making decoration pipe.

2. Continuous casting billet produced by refine furnace, no joint, annealed by Continuous bright annealing furnaces,

3. Good quality and reasonable price.

Application: Chemical, petrochemical industry, oil/gas, mechanical, plant engineering and construction

- Q: What is the role of steel coils in the oil and gas industry?

- Steel coils play a crucial role in the oil and gas industry. They are primarily used for the transportation and storage of oil and gas products. These coils are typically made of high-quality steel and are designed to withstand the harsh conditions encountered during the extraction, processing, and distribution of oil and gas. One of the main functions of steel coils in the oil and gas industry is to serve as transportation containers. Oil and gas are often transported over long distances, either through pipelines or by tankers. Steel coils are used to construct these pipelines and storage tanks, providing a robust and secure means of transporting these valuable resources. The durable nature of steel ensures that the pipelines and storage facilities can withstand the pressure and temperature fluctuations that occur during the transportation process. Steel coils are also an essential component in the production of drilling equipment. The drilling process involves extracting oil and gas from deep underground reservoirs. Steel coils are used to manufacture various components of drilling rigs, such as pipes, casings, and wellheads. These components must be able to withstand high pressures and temperatures encountered during drilling operations. Steel coils provide the necessary strength and durability to ensure the reliability and safety of drilling equipment. Furthermore, steel coils are used in the construction of offshore platforms. These platforms serve as bases for drilling operations in offshore oilfields. The harsh marine environment, including saltwater exposure and strong winds, requires materials that can withstand corrosion and provide structural integrity. Steel coils are used to fabricate the structural components of these offshore platforms, ensuring they can withstand the challenging offshore conditions. In summary, steel coils play a vital role in the oil and gas industry. They are used for transportation and storage of oil and gas products, construction of pipelines and storage tanks, manufacturing of drilling equipment, and fabrication of offshore platforms. The strength, durability, and resistance to harsh conditions make steel coils an indispensable material in the oil and gas industry.

- Q: I have one and wonder how much force this can take since it does seem like you can bend it(Sure it's impossible with hands), but I don't want to try that cause i don't want to break it. Many people say that it's really hard and can handle a hammer smash? is that true and can it even make it through more force. Cause steel is harder than iron and iron is pretty hard... So how much can i trust this locks security, i mean if i put at at a door would some thiefes be able to break it, if they had the right tools??

- Have you ever watched any of the shows where people are buying lockers at storage facilities? This style lock is used quite often. The reason for the small shackle is to prevent someone from using bolt cutters. Unfortunately, if a thief has a cordless right angle grinder with the right cutting blade they will still be able to remove it. That is what the guys at most of these auctions use to remove them in 10-15 seconds.

- Q: What is the role of steel coils in the production of industrial machinery?

- Steel coils play a crucial role in the production of industrial machinery as they serve as the raw material for various components and parts. The coils are often used to fabricate structural frames, gears, shafts, and other essential elements that provide strength, durability, and stability to the machinery. The versatility and strength of steel make it an ideal material for withstanding the rigorous demands of industrial applications, ensuring the reliability and performance of the machinery.

- Q: What are the dimensions of a typical steel coil?

- The dimensions of a typical steel coil can vary depending on the manufacturer and specific application, but common dimensions include thicknesses ranging from 0.015 inches to 0.5 inches, widths between 24 inches and 72 inches, and coil weights ranging from a few thousand pounds to over 50,000 pounds.

- Q: What is the average shelf life of a steel coil?

- The average shelf life of a steel coil can vary depending on various factors such as the type of steel, storage conditions, and handling practices. However, under ideal conditions, steel coils can typically be stored for several years without significant deterioration or loss in quality.

- Q: it seems like the hardness of Stainless steel, i saw 410c stainless stell, i saw 440c stainless steel, what does it means anyway?

- It's okorder / Stainless steel Grades [list is not exhaustive] 200 Series—austenitic chromium-nickel-manganese alloys 300 Series—austenitic chromium-nickel alloys Type 301—highly ductile, for formed products. Also hardens rapidly during mechanical working. Good weldability. Better wear resistance and fatigue strength than 304. Type 302—same corrosion resistance as 304, with slightly higher strength due to additional carbon.

- Q: How are steel coils inspected for paint adhesion?

- Various methods and techniques are utilized to inspect the adhesion of paint on steel coils. One commonly employed method is the tape test, which involves pressing adhesive tape onto the painted surface and swiftly removing it. The amount of paint that is lifted off by the tape is then examined to assess the adhesion. If the paint adheres well to the steel, only a minimal amount of paint will be removed. Another method employed is the crosshatch adhesion test. This test entails making parallel cuts on the painted surface using a sharp blade, creating a crosshatch pattern. A piece of adhesive tape is then applied over the cuts and rapidly pulled off. The evaluation of the paint that is removed from the crosshatched area determines the adhesion. Furthermore, a visual inspection is frequently conducted to evaluate the overall appearance and adhesion of the paint. Inspectors search for any indications of cracking, peeling, or bubbling, which may indicate poor adhesion. They also check for any areas where the paint may have chipped or flaked off. Moreover, various laboratory tests can be conducted to assess the paint adhesion on steel coils. These tests may include techniques like the pull-off test, where a specialized device is used to measure the force required to remove a small section of the paint from the surface. Other tests may involve subjecting the painted surface to extreme temperature or humidity conditions to assess the paint's performance under different environmental factors. In summary, a combination of visual inspections, tape tests, crosshatch adhesion tests, and laboratory tests are employed to thoroughly inspect steel coils for paint adhesion. These tests ensure that the paint adheres effectively to the steel surface, resulting in a durable and long-lasting finish.

- Q: How are steel coils used in the manufacturing of furniture?

- Steel coils are used in the manufacturing of furniture to provide structural support and stability. They are commonly used in the construction of sofa frames and mattress bases to ensure durability and longevity. The coils are typically formed into springs, which are then incorporated into the furniture to enhance comfort and provide a responsive seating or sleeping surface.

- Q: I have a steel string, Yamaha acoustic guitar that I am learning to play at home. But at school I use a rented nylon string guitar. I like the feel of the nylon strings better then the steel strings and i was wondering if i can just switch strings or if i should just get another guitar. Can anyone help?

- No, a steel string guitar is built and braced for the greater tension of steel strings, which means it's too heavily built to respond properly to nylon strings. It would sound awful. Besides, the slots in the nut are too narrow on a steel-string, the action is too low, and the bridge is made for ball end strings (most high quality nylon strings are plain end). And you would have to turn the narrow string posts on steel-string tuners forever to get anywhere with stretchy nylon strings.

- Q: i want to know what is light gauge steel and the diffrences between light gauge steel and steel for roof truss.

- guage means thickness.

Send your message to us

Hot Sale Grade of Stainless Steel Coil for Constructions

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords