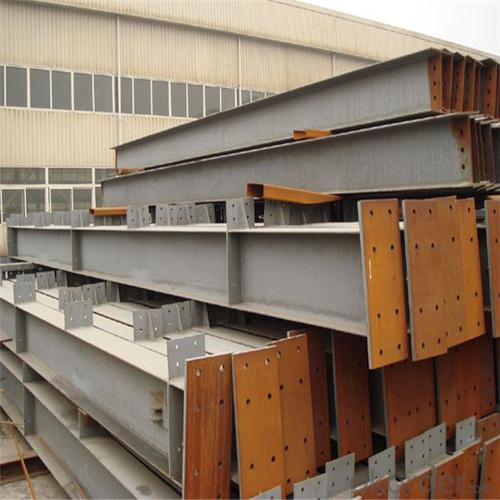

Hot Rolling Dip Galvanized H Beams Price per Kg

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Quick Details

Place of Origin: | Tianjin, China (Mainland) | Grade: | Q235,Q345,Q215,Q195,20# | Technique: | Hot Rolled |

Thickness: | 3.2-6.5mm | Application: | Structural Beam | Length: | 6-12m, generally 12m, or according to your order |

Standard: | JIS, GB/T11263-2010/JISG3192-2008/EN10163 | Flange Width: | 58,59,123mm | Flange Thickness: | 4.5-6mm |

Web Width: | 118,119, 120mm | Web Thickness: | 4.5-6mm | Brand Name: | Yuxing |

Model Number: | HT 125x60/125x125 | product name: | Structural carbon steel h beam profile H iron beam (IPE,UPE,HEA,HEB) | Steel Grade(Equal International) 1: | SM490,SS400,S185,St33,S235JR,St37-2 |

Steel Grade(Equal International) 2: | ASTM A106/A106M A,S235JO, St37-3,E295, St50-2 | Steel Grade(Equal International) 3: | St50-2,S355JRH, ASTM A106/A106M C | Technical Method of Surface Treatment: | Hot-dipped galvanized |

Not of Specification: | The specification below in the table is more accurate | application: | structural beam | shape: | H beam |

We can provide qualify goods,competitive price and speedy delivery.

Products Description

Description | High Frenquency Thin-walled H Beam | |

Product Name | H Beam | |

Specification | Height:75-500mm Width:50-250mm | |

Standard | GB700-1998,GB/T1591-1994 | |

Material | Q235B,Q345B | |

Application | a. Bridge and post structures in industry and civil use of steel construction. | |

Certificates | ISO,SGS,BV,TUV,Lloyd | |

MOQ | 20 tons or according to customers’ requirement. | |

Port of Delivery | Tianjin Port of China | |

Remarks | We can provide qualify goods,competitive price and speedy delivery |

Packaging & Delivery

Packaging Details: | Packed with waterproof paper and steel banding. |

Delivery Detail: | 15-25 |

FAQ

1. How can I get some samples?

We are honored to offer you samples. New clients are expected to pay for the courier cost. The samples are free for you.

2 Do you have any certificates?

Our products passed inspection of SGS, FDA, and CE Quality is priority! Every worker keeps the QC from the very beginning to the very end, Quality control department especially responsible for quality checking in each process.

3 Can your factory print or emboss my logo on the goods?

Yes, we can print or emboss the logo on the goods or their packing box.

4 What information should I let you know if I want to get a quotation?

1) The specification of products (length x width x thickness);

2) The temper and alloy.

3) The final product you will use to be made

4 It will be better if you can show us the pictures or design sketch. Samples will be best for clarifying. If not, we will recommend relevant products with details for reference.We usually produce goods based on customers

Samples or based on customers’ picture, logo, sizes etc.

- Q: How are steel H-beams different from other types of beams?

- Steel H-beams, also known as H-sections, are distinct from other types of beams due to their specific shape and structural properties. The main difference lies in their cross-sectional shape, which resembles the letter "H." This unique shape provides significant advantages over other beam types. Firstly, the H-beam's shape allows for a higher load-bearing capacity compared to other beams with similar weight. This is because the shape of the H-beam distributes the weight evenly along its length, maximizing its ability to withstand heavy loads. As a result, H-beams are widely used in construction projects that require strong and durable structural support, such as in the construction of high-rise buildings, bridges, and industrial facilities. Secondly, H-beams offer greater structural stability. The flanges, or top and bottom horizontal sections of the H-beam, provide resistance against bending and twisting forces. This characteristic makes H-beams more resistant to deformations and enables them to maintain their shape under heavy loads. Furthermore, the web, or vertical section of the H-beam, provides additional support and rigidity, ensuring the overall stability of the structure. Another key advantage of H-beams is their versatility. Due to their inherent strength and stability, H-beams can span longer distances without the need for intermediate supports. This allows for larger open spaces and more flexible architectural designs. Additionally, H-beams can be easily welded together to create longer beams, further expanding their application possibilities. Lastly, H-beams offer cost-effectiveness. Despite their robustness, H-beams are relatively lightweight compared to their load-bearing capacity. This reduces transportation costs and simplifies the installation process, making them a cost-effective choice for construction projects. In summary, steel H-beams differ from other types of beams due to their unique cross-sectional shape, which provides increased load-bearing capacity, structural stability, versatility, and cost-effectiveness. These characteristics make H-beams the preferred choice for various construction applications where strength, durability, and efficiency are crucial factors.

- Q: Can steel H-beams be used for railway bridges?

- Yes, steel H-beams can be used for railway bridges. Steel H-beams are commonly used in the construction of railway bridges due to their strength and durability. They are capable of supporting heavy loads and providing the necessary structural stability needed for a railway bridge. Additionally, steel H-beams can be easily fabricated and installed, making them a practical choice for railway bridge construction. However, it is important to note that the specific design and specifications of the railway bridge should be analyzed and approved by professional engineers to ensure its safety and efficiency.

- Q: Can steel H-beams be used for supporting agricultural structures?

- Certainly, agricultural structures can indeed be supported by steel H-beams. Renowned for their robustness and longevity, steel H-beams are well-suited for a wide range of purposes, including agricultural structures. Their exceptional ability to bear heavy loads and endure diverse environmental conditions is a testament to their strength. Steel H-beams offer a dependable and enduring support system for constructing barns, greenhouses, storage buildings, and other agricultural structures. Moreover, steel boasts resistance against pests, rot, and fire, rendering it an optimal choice for agricultural applications where these factors carry significant weight.

- Q: Can steel H-beams be used in marine environments?

- Yes, steel H-beams can be used in marine environments, but they require proper protection and maintenance to prevent corrosion. Marine environments are known for their high levels of moisture, saltwater exposure, and harsh weather conditions, all of which can accelerate the corrosion process of steel. To mitigate these risks, steel H-beams used in marine environments should be made from corrosion-resistant materials, such as stainless steel or galvanized steel. Stainless steel is especially suitable for marine environments due to its high resistance to corrosion and rust. It contains a significant amount of chromium, which forms a thin, passive layer on the surface of the steel, protecting it from the corrosive effects of saltwater and moisture. Stainless steel H-beams can withstand the harsh marine environment without significant degradation, making them a popular choice for applications such as piers, bridges, and offshore structures. Galvanized steel is another viable option for marine environments. It is carbon steel that has been coated with a layer of zinc, which acts as a sacrificial barrier against corrosion. The zinc coating corrodes first, protecting the underlying steel from direct exposure to saltwater and moisture. However, galvanized steel may not be as durable as stainless steel in highly corrosive marine environments, and the protective zinc coating can wear off over time, requiring periodic maintenance and reapplication of the coating. Regardless of the type of steel used, regular maintenance and inspections are crucial to ensure the integrity of H-beams in marine environments. This includes regular cleaning to remove salt deposits, repainting or re-galvanizing as needed, and addressing any signs of corrosion or damage promptly. Additionally, proper design considerations should be made to account for the specific challenges posed by marine environments, such as tidal forces, wave impact, and temperature fluctuations. In summary, steel H-beams can be used in marine environments, provided they are made from corrosion-resistant materials like stainless steel or galvanized steel and are properly maintained. With the right precautions, these beams can withstand the harsh conditions of marine environments, making them a reliable choice for various marine structures and applications.

- Q: How do steel H-beams perform in extreme weather conditions, such as high winds or heavy snow?

- Steel H-beams exhibit superior strength and durability, rendering them highly dependable in harsh weather conditions such as strong winds or heavy snowfall. Their distinctive shape and structural design effectively combat bending, twisting, and buckling forces, making them an ideal solution for confronting the challenges posed by severe weather. During periods of high winds, steel H-beams demonstrate outstanding performance due to their exceptional stiffness and ability to withstand wind loads. The H-shaped cross-section of the beam enhances stability and prevents deflection or damage even in the face of powerful gusts. This characteristic makes H-beams a favored choice for structures situated in hurricane-prone areas or regions with frequent high winds. Likewise, steel H-beams are exceptionally well-equipped to handle substantial snow loads. Their robust construction and high load-bearing capacity enable them to support the weight of accumulated snow without experiencing significant deformation or failure. This feature is especially crucial in areas that experience frequent snowstorms, as H-beams guarantee the structural integrity of buildings, bridges, or other infrastructures in such extreme conditions. Furthermore, steel H-beams not only resist wind and snow loads but also exhibit remarkable durability against corrosion and rust. This is achieved through the application of protective coatings and treatments during the manufacturing process. These coatings prevent the formation of rust and ensure the long-lasting performance of the beams, even in harsh weather environments. In conclusion, steel H-beams have a well-established reputation for exceptional performance in extreme weather conditions such as high winds or heavy snow. Their strength, stability, and resistance to external forces and corrosion make them a reliable choice for a variety of construction projects. This provides engineers, architects, and property owners with peace of mind, knowing that their structures will remain intact even in the face of severe weather.

- Q: Use H section steel to make the beam, the span of 8 meters, the floor slab, what's the minimum H steel? What's the model?

- Look, how many objects do you want to lift? If it's 5T, it should be OK. If it's 10T, you have to use 30H steel.

- Q: Can steel H-beams be used in the construction of telecommunications infrastructure?

- Certainly! Steel H-beams are indeed suitable for the construction of telecommunications infrastructure. Their high strength-to-weight ratio makes them an excellent choice for supporting heavy loads, which is why they are commonly used in construction. In addition to this, H-beams offer exceptional structural integrity and stability, making them an ideal option for various applications such as telecommunications towers, antennas, and equipment shelters. Furthermore, steel H-beams can endure extreme weather conditions and provide the necessary support for the installation and maintenance of telecommunications equipment. Moreover, they can be easily fabricated and assembled, allowing for efficient construction and flexibility in design. All in all, steel H-beams are a dependable and long-lasting choice for the construction of telecommunications infrastructure.

- Q: Are steel H-beams resistant to termites?

- No, steel H-beams are not resistant to termites. Termites are known for their ability to infest and damage wood, as they feed on cellulose present in natural materials. Since steel H-beams are made of metal, they do not contain cellulose and are not susceptible to termite infestation. Therefore, steel H-beams are an ideal choice for construction projects in termite-prone areas, as they provide a strong and durable alternative to traditional wooden beams.

- Q: What are the different types of steel H-beams available in the market?

- There are several different types of steel H-beams available in the market, each designed for specific applications and structural requirements. Some of the common types include: 1. Wide flange beams (W-beams): These are the most commonly used type of H-beams, featuring a wide flange section and parallel flanges. They provide excellent load-bearing capabilities and are suitable for various construction projects such as bridges, buildings, and supporting heavy loads. 2. I-beams: Also known as American Standard Beams (S-beams), these H-beams have narrower flanges compared to wide flange beams. They are commonly used in structural steel construction, as well as for columns and beams in residential and commercial buildings. 3. H-piles: These H-beams have a wider flange section and are primarily used as foundation piles in deep foundation systems. They are driven into the ground to provide support and stability for structures such as bridges, piers, and buildings. 4. Junior beams: These are smaller-sized H-beams, often used in light-duty applications or where space is limited. They are commonly used in residential construction, as well as in the manufacturing of machinery and equipment. 5. Specialized H-beams: There are also specialized H-beams available in the market, such as stainless steel H-beams, which are corrosion-resistant and suitable for applications in environments with high moisture or chemical exposure. Additionally, there are high-strength H-beams used in industries such as aerospace and automotive, where strength and durability are critical. Overall, the availability of different types of steel H-beams ensures that there is a suitable option for every construction or structural project, considering factors like load requirements, space limitations, and environmental conditions. It is important to consult with structural engineers or industry professionals to determine the most appropriate type of H-beam for a specific application.

- Q: Can steel H-beams be used for sports arenas?

- Yes, steel H-beams can be used for sports arenas. They are commonly used for structural support in large and complex building projects, including sports arenas, due to their strength, durability, and ability to withstand heavy loads. The use of steel H-beams provides a reliable and sturdy framework for the construction of sports arenas, ensuring the safety and stability of the structure.

Send your message to us

Hot Rolling Dip Galvanized H Beams Price per Kg

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords