Hot Rolled Steel Strip Coils Q195 Q235 in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 22223333 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Applications of Steel Strip Coils:

1:Chemical industry equipment, Industrial tanks

2:Medical Instruments,Tableware, Kitchen utensil,kitchen ware

3:Architectural purpose, Milk & Food processing facilities

4:Hospital Equipment, interior Exterior decoration for building

5:Architectural purposes, escalators, kitchen ware,vehicles

Festures of Steel Strip Coils:

1. Each coil is closely covered by oil paper or plastic film.

2. Outside it is firmly packed with sack cloth or compound paper.

3. Steel strap or PP strap to pack the outside to ensure safety.

4. On/about 1000kgs to be packed with one wooden pallet.

5. Strips can be loaded to 20'FCL without pallet if required by customer.

6. LCL shipment can also be arranged once required by the customer.

Specifications of Steel Strip Coils:

| Description | Hot Rolled Steel Strip |

| Brand | Tianjin Metallurgical No.Steel Group |

| Specification | 1.2-6.0mm*70mm |

| Standard | AISI,ASTM,BS,DIN,GB,JIS |

| Material | Q195,Q215,Q215B,Q235,Q235B |

| Application | Widly used in welding steel pipes, and bicycle making etc. |

| Certificates | BV,SGS,ISO etc. |

| MOQ | 20 tons or according to customers’ requirement. |

| Port of Delivery | Tianjin Port of China |

| Remarks | We can provide qualify goods,competitive price and speedy delivery |

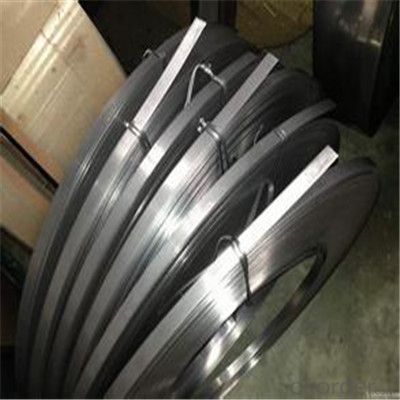

Images of Steel Strip Coils:

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days.

- Q: How are steel strips processed for surface embossing?

- Steel strips are processed for surface embossing through a series of steps to achieve the desired texture and pattern. First, the steel strips are cleaned and inspected for any imperfections or defects. This ensures that the surface is smooth and free from any contaminants that could affect the embossing process. Next, the strips are passed through a machine called a rolling mill, which applies pressure to the surface of the steel. The rolling mill is equipped with embossing rolls that have the desired pattern engraved on them. As the steel passes through the rolls, the pattern is transferred onto the surface of the strip. To enhance the embossed pattern and make it more visually appealing, the steel strips can undergo additional processes such as tempering or annealing. These heat treatments help to improve the flexibility and durability of the steel while also enhancing the embossed pattern. After the embossing process is complete, the steel strips may undergo further finishing processes such as cleaning, coating, or polishing to enhance the appearance and protect the surface from corrosion. Overall, the process of surface embossing steel strips involves cleaning, inspection, rolling through embossing rolls, optional heat treatments, and finishing processes. These steps ensure that the steel strips are transformed into visually appealing and durable products with embossed patterns.

- Q: What are the different types of slitting techniques for steel strips?

- There are several different types of slitting techniques that are commonly used for steel strips. These techniques are employed to cut steel strips into narrower widths for various applications. Some of the main types of slitting techniques include: 1. Rotary Shear Slitting: This technique involves using a rotating circular blade to cut through the steel strip. The blade moves in a continuous motion, resulting in a clean and precise cut. Rotary shear slitting is ideal for high-speed production lines and is commonly used in industries such as automotive and construction. 2. Crush Cut Slitting: In crush cut slitting, a hardened steel blade is pressed against a softer material, such as rubber or polyurethane. This type of slitting technique is often used for softer steel materials or for materials that are prone to deformation. Crush cut slitting is known for its ability to produce clean, burr-free edges. 3. Razor Slitting: Razor slitting involves the use of a sharp, razor-like blade to cut through the steel strip. This technique is commonly used for thinner gauge materials and provides precise, narrow cuts. Razor slitting is often used in industries such as packaging and electronics. 4. Scissor Slitting: Scissor slitting is a technique that utilizes two blades that move in a scissor-like motion to cut through the steel strip. This method is often used for thicker gauge materials or for materials that are difficult to cut. Scissor slitting allows for greater control over the cutting process and is commonly used in industries such as aerospace and manufacturing. 5. Laser Slitting: Laser slitting involves using a high-powered laser beam to cut through the steel strip. This technique provides precise and clean cuts and is often used for high-value or specialty materials. Laser slitting is commonly used in industries such as medical device manufacturing and precision engineering. Each of these slitting techniques offers unique advantages and is suitable for different types of steel strips. The choice of slitting technique depends on factors such as the desired width of the steel strip, the material properties, and the specific requirements of the application.

- Q: How are steel strips tested for hardness?

- Steel strips are typically tested for hardness using a method called the Rockwell hardness test. This involves applying a specific amount of force to the surface of the steel strip using a diamond or carbide ball indenter, and then measuring the depth of the indentation. The hardness value is determined based on the depth of the indentation, providing an accurate measure of the steel strip's hardness.

- Q: How are steel strips processed for stamping?

- Steel strips are processed for stamping through a series of steps including cleaning, annealing, and lubrication. The cleaning process removes any impurities or contaminants from the surface of the strip. Annealing helps to soften the steel and improve its formability. Finally, lubrication is applied to reduce friction during the stamping process, ensuring smooth and accurate shaping of the steel strips.

- Q: Are steel strips suitable for high-precision applications?

- Steel strips can be suitable for high-precision applications, depending on the specific requirements of the application. Steel strips offer excellent strength, durability, and dimensional stability, making them suitable for various precision applications. However, factors like the quality of the steel, surface finish, and manufacturing process must be considered to ensure the desired level of precision.

- Q: What are the main factors affecting the machinability of steel strips?

- The main factors affecting the machinability of steel strips include the composition of the steel, such as the presence of alloying elements, the hardness and microstructure of the steel, the cutting tool material and geometry, the cutting speed and feed rate, and the lubrication and cooling conditions during machining.

- Q: Are steel strips suitable for making HVAC components?

- Yes, steel strips are commonly used for making HVAC components due to their strength, durability, and corrosion resistance. They offer the necessary structural integrity and can withstand the demanding conditions within heating, ventilation, and air conditioning systems. Additionally, steel strips can be easily formed and fabricated into various shapes and sizes, making them highly suitable for manufacturing HVAC components.

- Q: How do steel strips perform under high temperatures?

- Steel strips generally perform well under high temperatures. Steel is known for its high melting point, which ranges from 1370°C to 1520°C (2500°F to 2750°F), depending on the specific type of steel. This means that steel strips can withstand extremely high temperatures without melting or losing their structural integrity. At elevated temperatures, steel strips also exhibit good thermal stability. They have a low thermal expansion coefficient, which means they expand and contract less compared to other materials. This property helps prevent warping or deformation of the strips when exposed to high temperatures. Steel strips also possess excellent strength and hardness even at elevated temperatures. While the strength of steel decreases slightly as temperatures rise, it still remains much stronger than many other materials. This makes steel strips suitable for applications where high temperature resistance and mechanical strength are essential, such as in furnaces, boilers, and heat exchangers. However, it is important to note that prolonged exposure to extremely high temperatures can lead to some changes in the properties of steel strips. At very high temperatures, steel can undergo oxidation or scaling, which may result in a loss of surface quality or corrosion resistance. Additionally, repeated heating and cooling cycles can lead to thermal fatigue, causing the steel to become more brittle over time. Therefore, it is necessary to consider these factors and choose the appropriate steel grade and surface treatment to ensure optimal performance under high temperature conditions.

- Q: Are steel strips suitable for making architectural staircases?

- Architectural staircases can be effectively constructed using steel strips. Steel, being a versatile and long-lasting material, provides numerous advantages for staircase construction. To begin with, steel strips possess exceptional strength and stability, enabling them to bear heavy loads and ensure user safety. This is especially crucial for architectural staircases that may encounter significant foot traffic or need to accommodate a large number of individuals. Moreover, steel strips can be fabricated and customized to create a variety of architectural designs and styles. They can be easily molded, bent, and joined together to achieve distinct and innovative staircase designs. This flexibility empowers architects and designers to fashion staircases that seamlessly integrate with the overall aesthetic of the building or space. In addition, steel strips exhibit remarkable resistance to corrosion, which is especially advantageous for staircases situated in outdoor or high-moisture environments. This durability ensures that the staircases will have an extended lifespan and necessitate minimal maintenance over time. Furthermore, steel strips offer a sleek and modern appearance that can enhance the overall visual appeal of the staircase. They can be finished with various coatings, such as powder coating or painting, to attain the desired look and feel. Lastly, steel is an environmentally friendly choice for staircase construction, as it is a sustainable material with a high recyclability rate. All in all, steel strips prove to be a suitable material for creating architectural staircases due to their strength, versatility, durability, corrosion resistance, aesthetic appeal, and sustainability.

- Q: How are steel strips processed for sealing?

- To ensure the quality and effectiveness of steel strips for sealing, a series of steps are taken. It all begins with the selection of high-quality steel, which is thoroughly cleaned to eliminate any impurities or contaminants. Once cleaned, the steel strips are shaped and thickened using specialized machinery. After shaping, the steel strips are annealed to release internal stress and enhance their flexibility. This involves heating the strips to a specific temperature and slowly cooling them, resulting in improved physical properties for sealing purposes. Following annealing, a surface treatment process is applied to the steel strips, such as electroplating, in order to increase their resistance to corrosion and durability. This process may involve the application of a thin layer of zinc or other protective coatings to prevent rusting and ensure long-lasting sealing performance. Once the surface treatment is completed, the steel strips are precisely cut to the desired length and width using cutting tools or machinery. This allows for customization and ensures accurate sizing for specific sealing applications. Finally, additional processes like edge trimming or deburring may be carried out to eliminate any sharp or rough edges that could potentially compromise the sealing performance. This step guarantees a smooth and uniform surface, which is crucial for effective sealing. In conclusion, the processing of steel strips for sealing involves a combination of cleaning, shaping, annealing, surface treatment, cutting, and finishing steps. These processes are executed meticulously to meet the required specifications for sealing applications, resulting in a dependable and long-lasting solution.

Send your message to us

Hot Rolled Steel Strip Coils Q195 Q235 in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 22223333 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords