Hot Rolled Steel Strip Coils Q195 Q235 from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 344 m.t.

- Supply Capability:

- 2222454 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Applications of Steel Strip Coils:

1:Chemical industry equipment, Industrial tanks

2:Medical Instruments,Tableware, Kitchen utensil,kitchen ware

3:Architectural purpose, Milk & Food processing facilities

4:Hospital Equipment, interior Exterior decoration for building

5:Architectural purposes, escalators, kitchen ware,vehicles

Festures of Steel Strip Coils:

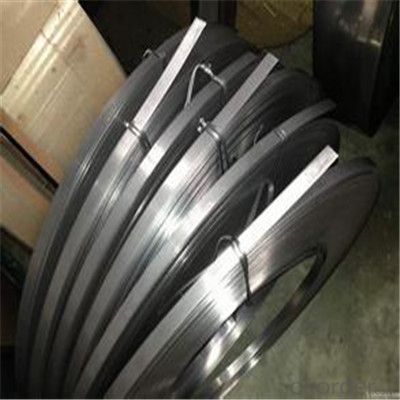

1. Each coil is closely covered by oil paper or plastic film.

2. Outside it is firmly packed with sack cloth or compound paper.

3. Steel strap or PP strap to pack the outside to ensure safety.

4. On/about 1000kgs to be packed with one wooden pallet.

5. Strips can be loaded to 20'FCL without pallet if required by customer.

6. LCL shipment can also be arranged once required by the customer.

Specifications of Steel Strip Coils:

| Description | Hot Rolled Steel Strip |

| Brand | Tianjin Metallurgical No.Steel Group |

| Specification | 1.2-6.0mm*70mm |

| Standard | AISI,ASTM,BS,DIN,GB,JIS |

| Material | Q195,Q215,Q215B,Q235,Q235B |

| Application | Widly used in welding steel pipes, and bicycle making etc. |

| Certificates | BV,SGS,ISO etc. |

| MOQ | 20 tons or according to customers’ requirement. |

| Port of Delivery | Tianjin Port of China |

| Remarks | We can provide qualify goods,competitive price and speedy delivery |

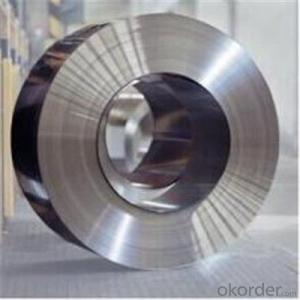

Images of Steel Strip Coils:

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days.

- Q: How are steel strips processed for leveling?

- Through a series of mechanical and thermal treatments, steel strips are processed for leveling. The initial step is to uncoil the steel strips from a coil and feed them into a leveling machine. This machine contains a set of rollers that exert pressure on the strips to eliminate any unevenness and distortions in the material. The leveling process commences with the entry set of rollers, gradually increasing tension and pressure on the strips. This pressure aids in flattening any curvatures or waves on the strip's surface. The strips are guided by a series of rollers throughout the leveling machine to ensure consistent and uniform pressure is applied across the entire width. In the leveling process, it is common to introduce heat treatments to enhance the ductility and facilitate the straightening of the steel. This is typically achieved through a heat treatment furnace, where the strips are heated to a specific temperature and then rapidly cooled. This thermal treatment softens the steel, making it more malleable and facilitating the leveling process. After the leveling and heat treatment, the steel strips undergo another set of rollers called tension levelers. These rollers apply tension to the strips, further eliminating any residual stresses or deformations. The tension levelers work in conjunction with the previous leveling machine to ensure a flat and even surface is achieved. Once the leveling process is complete, the steel strips may undergo additional processes such as slitting, coating, or further heat treatments, depending on the intended application. This guarantees that the final product meets the desired specifications in terms of thickness, surface quality, and mechanical properties. In summary, the leveling of steel strips involves a combination of mechanical and thermal treatments to eliminate distortions, curvatures, and stresses in the material. This process results in a flat and even surface, making the steel strips suitable for various industrial applications.

- Q: What is the creep resistance of a steel strip?

- The ability of a steel strip to withstand deformation or creep under prolonged stress at elevated temperatures is referred to as its creep resistance. Creep occurs when materials gradually deform over time when subjected to a consistent load or stress at high temperatures. This can be particularly critical in situations where the steel strip is exposed to high temperatures for extended durations. Several factors affect the creep resistance of a steel strip, including its composition, microstructure, temperature, and stress levels. Steel strips with higher amounts of alloying elements like chromium, molybdenum, and vanadium tend to exhibit superior creep resistance. Additionally, a fine and uniform microstructure with controlled grain size can enhance the steel strip's ability to resist creep. To assess the creep resistance of steel strips, testing methods such as creep tests are employed. These tests involve subjecting the strip to a constant stress or load at a specified temperature for an extended period and measuring the resulting deformation. The creep resistance is then determined by analyzing the material's deformation characteristics over time. Creep resistance is a crucial consideration in various industries, including power generation, aerospace, and automotive, where components are exposed to high temperatures and sustained stresses. By selecting a steel strip with high creep resistance, engineers and manufacturers can ensure the durability and dependability of their products in such demanding environments.

- Q: What is the corrosion resistance of steel strips?

- Steel strips have good corrosion resistance due to the presence of chromium, which forms a protective oxide layer on the surface of the steel, preventing further corrosion. Additionally, other alloying elements such as nickel and molybdenum can enhance the corrosion resistance of steel strips, making them suitable for various applications, including outdoor and marine environments.

- Q: How do steel strips perform in structural components?

- Steel strips perform exceptionally well in structural components. Due to their high strength, durability, and flexibility, steel strips provide excellent support and stability to various structures. They can effectively distribute loads, resist deformation, and withstand extreme conditions, making them ideal for applications such as beams, columns, trusses, and frames. Additionally, steel strips offer versatility in design, enabling engineers to create efficient and safe structures.

- Q: How are steel strips protected against rust?

- Steel strips are protected against rust through various methods such as applying a protective coating, galvanization, or using corrosion-resistant alloys.

- Q: What are the different types of joints used for steel strips?

- For steel strips, there are various types of joints available depending on the specific application and requirements. The most commonly used joints include: 1. Butt joint: This is the simplest and widely utilized joint for steel strips. It involves aligning the ends of two strips and joining them together through welding or bolting. 2. Lap joint: In this joint, one strip overlaps the other and is subsequently welded or bolted together. This type of joint offers enhanced strength and stability. 3. Scarf joint: A scarf joint is a variant of the lap joint where the overlapping ends are cut at an angle to create a seamless transition between the strips. This joint is often employed when a continuous appearance is desired. 4. T-joint: In a T-joint, one strip is perpendicular to the other, forming a T shape. This joint is commonly used to join steel strips at right angles. 5. Corner joint: Similar to a T-joint, a corner joint involves both strips being at a 45-degree angle, creating a corner. This type of joint is frequently utilized in box or frame structures. 6. Butt joint with backing strip: This joint employs a backing strip placed behind the joint to provide additional support and strength. The backing strip is typically joined to the steel strips through welding or bolting. 7. Overlap joint: In an overlap joint, one strip is positioned over the other with a small gap between them. This joint is commonly found in applications where flexibility is required, such as in conveyor belts. These examples showcase only a few of the available joint options for steel strips. The choice of joint will depend on factors such as strength requirements, the application, and the desired final appearance of the product.

- Q: How are steel strips polished for aesthetic purposes?

- To achieve an aesthetically pleasing polish on steel strips, a multi-step process utilizing various techniques is employed. The initial step involves a thorough cleaning of the strip to eliminate any dirt, grease, or contaminants, which can be accomplished using a solvent or degreaser. Subsequently, the strip is subject to sanding, employing progressively finer grits of sandpaper or abrasive pads. This aids in the elimination of surface imperfections, scratches, and rough areas, with the objective of attaining a smooth and uniform surface. Following the sanding phase, the strip undergoes a buffing procedure. Buffing entails the utilization of a rotating wheel or polishing machine equipped with a soft cloth or buffing pad. The wheel or pad is coated with a polishing compound, available in the form of paste, liquid, or powder. This compound assists in the eradication of any remaining scratches and imparts a lustrous shine to the steel strip. The level of polish desired dictates the need for multiple buffing stages, incorporating different compounds possessing varying levels of abrasiveness. It may also necessitate the use of diverse types of wheels or pads, each specifically designed for distinct polishing requirements. Once the desired level of polish is achieved, the strip is meticulously cleaned once more to eliminate any residue from the polishing compounds. This ensures a pristine and sleek finish. Lastly, the strip may be subjected to additional treatments, such as electroplating or coating, to enhance its aesthetic appeal and provide protection against corrosion. In summary, the process of polishing steel strips for aesthetic purposes encompasses a combination of cleaning, sanding, buffing, and finishing, resulting in a smooth, radiant, and visually captivating surface.

- Q: What are the factors to consider when selecting steel strips for a specific application?

- When selecting steel strips for a specific application, several factors need to be considered. These include the desired mechanical properties such as strength, hardness, and ductility, as well as the required corrosion resistance. Other factors to consider are the dimensions and thickness of the strips, the manufacturing process, and the intended environment and conditions of use. Additionally, cost, availability, and any specific industry standards or certifications may also influence the selection process.

- Q: How are steel strips used in the production of solar panels?

- Steel strips are an integral part of the production process of solar panels. These strips are primarily used for framing and providing structural support to the solar panels. They are typically made of galvanized steel, which is known for its durability and resistance to corrosion. The steel strips are cut into specific lengths and shapes to form the framework of the solar panel. This framework holds all the components of the panel together, including the glass cover, solar cells, and backsheet. The steel strips are fastened securely to ensure the stability of the panel, especially during installation and during exposure to various weather conditions. Additionally, steel strips play a crucial role in maintaining the overall integrity of the solar panel. They act as a protective barrier, shielding the delicate components of the panel from external forces such as wind, rain, and snow. By providing structural support, the steel strips help to prevent damage and ensure the longevity of the solar panel. Moreover, steel strips are essential for the installation and mounting of solar panels. They are used to secure the panels onto rooftops or other surfaces, ensuring they are firmly fixed in place. This is especially important to maximize the solar panel's exposure to sunlight and optimize its energy production. In summary, steel strips are an essential component in the production of solar panels. They provide structural support, ensure the integrity of the panel, and facilitate its installation and mounting. By incorporating steel strips into the manufacturing process, solar panels are made more robust, reliable, and efficient, contributing to the overall sustainability and effectiveness of solar energy systems.

- Q: How are steel strips used in the production of heat exchangers?

- Steel strips are commonly used in the production of heat exchangers as they provide structural support and help create the necessary heat transfer surfaces within the exchanger. These strips are often formed into fins or plates that enhance the heat transfer process by increasing the surface area for heat exchange. Additionally, steel strips offer durability and corrosion resistance, ensuring the longevity and efficiency of the heat exchanger in various applications.

Send your message to us

Hot Rolled Steel Strip Coils Q195 Q235 from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 344 m.t.

- Supply Capability:

- 2222454 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords