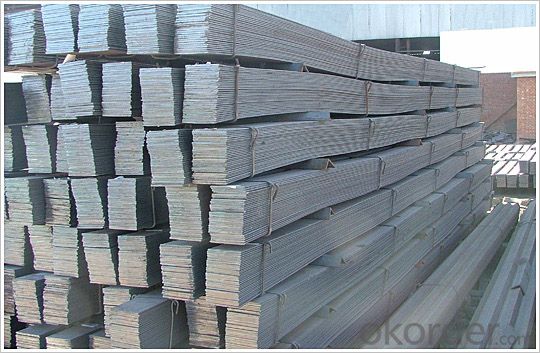

Flat Bars Hot Rolled Perforated (Hot Galvanized) Hot Dipped

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 29 m.t.

- Supply Capability:

- 24000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | within 10 days after receipt of deposit |

| Delivery Detail: | In bundles, load in containers |

Specifications

Hot dipped galvanized steel flat, galvanized steel flat bar

1.High quality

2. seafreight package

3.Lead time

4.MTC

Product Description

Hot dipped galvanized steel flat, galvanized steel flat bar

SPECIFICATIONS (MM)

HOT ROLLED FLAT BAR

1. STANDARD: GB704-1988

2. GRADE: Q195,Q215,Q235 Q345,ST-37,ST-53,S275JR.S355JR,SS400

3. THICKNESS: 8-30MM

4. WIDTH: 40-120MM

5. LENGTH: 6M/5.8M/3M/2M OR ACCORDING TO CUSTOMER'S REQUEST

STAINLESS FLAT BAR

1. GRADE: 201/202/ 201/201/301/304/304L/316/316l/317/310/

310S/309/309S /321/410/410S/420/430/439/416

2. TECHNIC: THICKNESS ABOVE 10MM IS FOR HOT ROLLED STAINLESS FLATE BA,

THICKNESS BELOW 10MM IS FOR COLD DRAWN STAINLESS FALAT BAR

4. WIDTH: 10-1000MM

5. LENGTH: 5.8M,6M ORACCORDING TO CUSTOMER'S REQUEST

ALLOY STEEL FLAT BAR PRICE PER TON

1. GRADE: 40Cr,42CrMo,40Mn,20CrMo,30CrMo,35CrMo,65Mn,60SiMnA,60CrMoA

50CCrVA

2. TECHNIC: HOT ROLLED ALLOY STEEL FLATE BA,

COLD DRAWN ALLOY STEEL FALAT BAR

4. WIDTH: 10-1000MM

5. LENGTH: 5.8M,6M ORACCORDING TO CUSTOMER'S REQUEST

SLITED FLAT BAR

1. STANDARD: GB704-1988

2. GRADE: Q195,Q215,Q235 Q345,ST-37,ST-53,S275JR.S355JR,SS400

3. THICKNESS: 1.5-30MM

4. WIDTH: 10-1000MM

5. LENGTH: 2M/3M/5.8M,6M ORACCORDING TO CUSTOMER'S REQUEST

- Q: Can steel flat bars be used in the manufacturing of material handling equipment?

- Certainly, material handling equipment can definitely incorporate steel flat bars. These bars, commonly produced from carbon steel, are renowned for their robustness, endurance, and adaptability. These attributes render them highly suitable for a multitude of applications within material handling equipment, including the construction of frames, supports, brackets, and other foundational components. Steel flat bars can be effortlessly welded, cut, and shaped into various forms and dimensions, enabling customization and versatility throughout the manufacturing process. Moreover, they possess exceptional load-bearing capabilities, making them well-suited for managing hefty loads and ensuring stability and dependability in material handling equipment. All in all, owing to their strength, durability, and ability to meet the exacting demands of such equipment, steel flat bars are a favored choice in material handling equipment manufacturing.

- Q: Are steel flat bars suitable for fabrication of industrial machinery?

- Yes, steel flat bars are suitable for the fabrication of industrial machinery. Steel flat bars are known for their high strength, durability, and versatility, making them a preferred choice in various industrial applications. They can be easily cut, welded, and formed into different shapes to meet specific requirements. Additionally, steel flat bars offer excellent load-bearing capabilities, ensuring the structural integrity and reliability of the machinery.

- Q: Can steel flat bars be used for making playground equipment?

- Yes, steel flat bars can be used for making playground equipment. Steel is a strong and durable material that can withstand heavy use and provide stability and safety for children. Steel flat bars can be used to construct various components of playground equipment such as swings, slides, climbers, and frames. The flat shape of the bars allows for easy fabrication and assembly, making them versatile for creating different designs and structures. Additionally, steel can be painted or coated to enhance its appearance and protect it from corrosion, further ensuring the longevity of the playground equipment.

- Q: Can steel flat bars be used for manufacturing scaffolding or construction supports?

- Yes, steel flat bars can be used for manufacturing scaffolding or construction supports. Steel flat bars are a popular choice due to their strength and durability. They can be easily welded together to create sturdy structures that can support heavy loads. Additionally, steel flat bars have good corrosion resistance, making them suitable for outdoor construction projects. However, it is important to ensure that the steel flat bars used for scaffolding or construction supports are of the appropriate size and quality, and meet the necessary safety standards and regulations.

- Q: How do you prevent rusting on steel flat bars?

- To prevent rusting on steel flat bars, there are several steps you can take: 1. Keep the bars dry: Moisture is a major contributor to rusting. Ensure that the flat bars are stored in a dry environment and avoid exposing them to water or excessive humidity. 2. Apply a protective coating: Applying a protective coating is an effective way to prevent rust formation. Options include paint, varnish, or a specialized rust-resistant coating. Make sure to choose a coating that is specifically designed for steel and can withstand the intended use of the flat bars. 3. Use galvanized steel: Galvanization is a process that involves coating steel with a layer of zinc. This protective layer acts as a barrier against moisture and prevents rusting. Galvanized steel flat bars are highly resistant to corrosion and can be a great choice if rust prevention is a priority. 4. Maintain proper ventilation: If the steel flat bars are used in an environment with high humidity or exposure to chemicals, adequate ventilation is crucial. Proper airflow helps to prevent the accumulation of moisture, reducing the risk of rust formation. 5. Regular cleaning and inspection: Regularly cleaning the steel flat bars and inspecting them for any signs of rust or damage is essential. If any rust spots are detected, they should be promptly addressed to prevent further corrosion. 6. Store the bars properly: When storing steel flat bars, ensure they are kept in a dry location away from any potential sources of moisture. Consider using storage racks or shelves to prevent direct contact with the ground or other surfaces that may accumulate moisture. By following these preventive measures, you can significantly reduce the chances of rusting on steel flat bars and prolong their lifespan.

- Q: Are steel flat bars available in different lengths and thicknesses?

- Indeed, various lengths and thicknesses of steel flat bars are readily obtainable. The lengths may differ based on the provider or producer, yet standard lengths encompass 6 feet, 8 feet, and 10 feet. Furthermore, steel flat bars can be procured in diverse thicknesses, such as 1/8 inch, 1/4 inch, 3/8 inch, and beyond. The assortment of available lengths and thicknesses permits adaptability in numerous construction and manufacturing applications, guaranteeing the existence of a fitting choice for distinct project necessities.

- Q: Where can I buy ground level bending machine?

- Galvanized flat steel and galvanized steel (or steel) for welding, reliable connection, should be in addition to the contact regions on both sides of the weld, should also direct the flat curved (or rectangular) and steel (or steel) and steel pipe welding, when welding on the steel pipe wrapped around the welding length 2 times less than the width of flat steel.

- Q: Are steel flat bars used in the construction of bridges?

- Yes, steel flat bars are commonly used in the construction of bridges. They provide structural support and stability, and are often used for components such as beams, braces, and reinforcement.

- Q: Can steel flat bars be used in electrical or electronic equipment?

- Yes, steel flat bars can be used in electrical or electronic equipment. Steel flat bars are often used as a mounting or support component in electrical or electronic equipment due to their strength and durability. They provide stability and structural integrity to the equipment, especially in applications where weight or load-bearing capacity is important. Additionally, steel flat bars can also be used as conductive elements in certain electrical or electronic systems, as they have good electrical conductivity properties. However, it is important to note that steel is a conductor of electricity, so proper insulation and grounding techniques should be followed to prevent any electrical hazards.

- Q: Are steel flat bars corrosion resistant?

- The resistance of steel flat bars to corrosion is not inherent. Instead, it depends on the type of steel used and the application of any treatments or coatings on the bars' surface. For instance, stainless steel flat bars possess high resistance to corrosion due to the presence of chromium, which creates a protective oxide layer. Conversely, carbon steel flat bars are more susceptible to corrosion, particularly in environments with high moisture or exposure to corrosive substances. To enhance the corrosion resistance of carbon steel flat bars, they can be galvanized or coated with protective substances such as paint or epoxy. When evaluating the corrosion resistance of steel flat bars, it is crucial to consider the specific type of steel employed and any supplementary treatments.

Send your message to us

Flat Bars Hot Rolled Perforated (Hot Galvanized) Hot Dipped

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 29 m.t.

- Supply Capability:

- 24000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords