Hot Rolled Steel Angle Bar Unqual Angle Bar Made In China High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

OKorder is offering Hot Rolled Steel Angle Bar Unqual Angle Bar Made In China High Quality at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Steel Angle Bar Unqual Angle Bar Made In China High Quality are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Hot Rolled Steel Angle Bar Unqual Angle Bar Made In China High Quality are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

1.Standards: JIS

2.Length: 6m,9m,12m

3.Material: SS400 or Equivalent

4. Size:

Size (mm) | Mass (mm) | Size (mm) | Mass (mm) |

75*50*5.0 | 4.8 | 75*50*8.0 | 7.43 |

75*50*6.0 | 5.66 | 100*75*6.0 | 8.04 |

Packaging & Delivery of Unequal Angle Steel

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

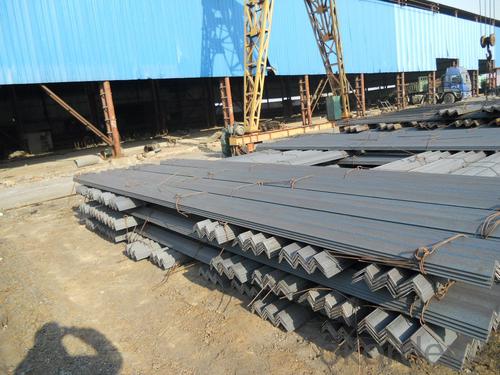

Images:

- Q: What is the maximum deflection allowed for a steel angle?

- The maximum deflection allowed for a steel angle depends on various factors such as the specific application, the load applied, and the desired safety factor. However, as a general guideline, the maximum deflection allowed for a steel angle is typically limited to 1/360th of its span length.

- Q: What are the different methods for cutting steel angles?

- There are several different methods for cutting steel angles, including using a bandsaw, a chop saw, an angle grinder, a plasma cutter, or a laser cutter. The choice of method depends on factors such as the thickness of the steel, accuracy requirements, and the desired finish.

- Q: How do you determine the appropriate size of steel angle for a specific application?

- To determine the appropriate size of steel angle for a specific application, factors such as the load it needs to bear, the length of the span, the type of material being supported, and any applicable building codes or regulations should be considered. Structural engineers or professionals with expertise in steel construction can perform calculations and analysis to determine the required size of steel angle based on these factors.

- Q: Can steel angles be used in pedestrian bridges?

- Pedestrian bridges can indeed make use of steel angles in their construction. The high strength-to-weight ratio and versatility of steel angles make them a common choice in bridge construction. These angles are frequently employed as structural elements, providing the necessary support, stability, and rigidity to the bridge structure. With their ability to withstand heavy loads and forces, steel angles are well-suited for pedestrian bridges, which must bear the weight of individuals walking across. Moreover, steel angles can be easily fabricated and welded, enabling flexibility in the design and construction of pedestrian bridges. All in all, steel angles are widely favored for constructing pedestrian bridges due to their durability, strength, and user-friendly nature.

- Q: What are the different types of steel angles used in agricultural applications?

- In agricultural applications, various types of steel angles are commonly utilized. These angles serve different purposes and possess distinct features. Here are some examples: 1. Equal Angle: This steel angle boasts equal sides and is frequently employed in agricultural structures like barns and sheds for structural reinforcement. Its stability and strength make it suitable for supporting heavy loads. 2. Unequal Angle: As the name implies, this steel angle has sides of unequal lengths. It finds widespread use in agricultural machinery, such as tractor attachments and implements. The uneven sides allow for precise positioning and attachment of various components. 3. Lipped Angle: Similar to equal angles, lipped angles have an added lip or flange on one side. This lip enhances support and rigidity, making it ideal for agricultural purposes that demand extra strength, such as fencing and gate posts. 4. Slotted Angle: Slotted angles are highly adaptable and can be adjusted to different angles as required. They are commonly employed in agricultural shelving systems, enabling farmers to create customized storage solutions for tools, equipment, and supplies. The slots present in these angles provide flexibility for modifying shelf heights. 5. Rolled Steel Angle: Rolled steel angles are created by rolling steel into angle-shaped sections. They are extensively used in agricultural construction for bracing, supporting beams, and framing. Rolled steel angles offer exceptional strength and durability, rendering them suitable for demanding agricultural environments. Each type of steel angle possesses unique characteristics and advantages. The selection of the appropriate angle depends on the specific agricultural application and the desired level of strength and support. Factors such as load-bearing capacity, durability, and resistance to corrosion should be carefully considered when choosing the suitable steel angle for agricultural use.

- Q: Can steel angles be used for window frames?

- Yes, steel angles can be used for window frames. Steel angles are commonly used in construction due to their strength and durability. They provide excellent structural support and can withstand heavy loads, making them suitable for window frames. Additionally, steel angles can be easily fabricated and customized to fit specific window sizes and shapes. They also offer resistance to corrosion, ensuring longevity and minimal maintenance requirements. Therefore, steel angles are a popular choice for window frames in various applications, including commercial buildings, residential homes, and industrial facilities.

- Q: Are steel angles suitable for supporting heavy machinery?

- Indeed, steel angles possess the necessary attributes to effectively support heavy machinery. Boasting strength, durability, and an elevated load-bearing capacity, these angles emerge as a prime selection for bolstering heavy machinery. Their prevalence in both industrial settings and construction ventures is a testament to their ability to furnish structural support. By either employing bolts or welding techniques, one can seamlessly amalgamate these angles, yielding a robust framework capable of withstanding the weight and vibrations engendered by heavy machinery. Moreover, the versatility of steel angles permits customization, facilitating the development of resilient and dependable support structures tailored to meet specific requirements posed by heavy machinery.

- Q: How do steel angles resist bending or deflection?

- Steel angles resist bending or deflection due to their shape and material properties. The design of steel angles, with their L-shaped cross-section, provides structural stability and strength, making them highly resistant to bending or deflection under load. The L-shape of steel angles creates two perpendicular legs, which distribute the applied load more efficiently compared to other shapes. This distribution of load allows the angles to resist bending forces, preventing them from deforming or deflecting significantly. The longer leg of the angle provides greater leverage and stiffness, enhancing its resistance to bending. Moreover, steel itself is a strong and rigid material, known for its high tensile and compressive strength. Steel angles are typically made from hot-rolled steel, which undergoes a process that further improves its structural properties. The combination of the L-shape design and the inherent strength of steel enables steel angles to withstand bending forces without significant deflection. Additionally, steel angles can be reinforced through various methods such as welding or bolting to increase their resistance to bending or deflection. Reinforcements add additional strength and stiffness to the angles, making them even more robust and capable of withstanding higher loads. In summary, steel angles resist bending or deflection due to their L-shape design, the inherent strength of steel, and possible reinforcements. These factors work together to provide structural stability and prevent excessive deformation, making steel angles a reliable choice for various construction and engineering applications.

- Q: Can steel angles be used as handrails?

- Yes, steel angles can be used as handrails. Steel angles provide strength and stability, making them suitable for use as handrails in various settings such as stairs, ramps, balconies, and walkways. They can be welded or bolted securely to provide a reliable grip and support for individuals while navigating these areas.

- Q: Can steel angles be used for manufacturing door frames?

- Yes, steel angles can be used for manufacturing door frames. Steel angles provide stability, strength, and durability, making them suitable for supporting and reinforcing door frames.

Send your message to us

Hot Rolled Steel Angle Bar Unqual Angle Bar Made In China High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords