Hot Rolled Spring Steel Round Bar 16mm with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

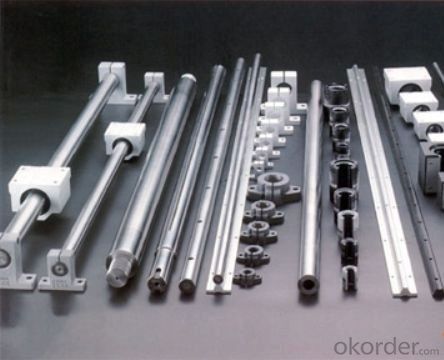

Product Description:

OKorder is offering Hot Rolled Spring Steel Round Bar 16mm with High Quality at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Spring Steel Round Bar 16mm with High Quality is widely used to make the bearing used in automobile, tractor engine, transmission and the wheel. And it also used to make the main bearing for the machine tools, electrical machinery, mining machinery, electric locomotives,mechanical ventilation and high speed of grinding wheel spindle etc

Product Advantages:

OKorder's Hot Rolled Spring Steel Round Bar 16mm with High Quality are durable, diversified and qualified.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: 20CrNiMoA 20CrNi2MoA 16Cr2Ni4MoA 12Cr2Ni3Mo5A 20Cr2Ni4A 20Cr2Ni2MoA

Cr4Mo4V Cr15Mo4 W9Cr4V2Mo W18Cr4V W6Mo5Cr4V2 5CrMnMo 60CrMnMoNi 37CrA 55SiMoVA etc

Certificates: ISO, SGS, BV, CIQ

Length:6m 8m 9m 12m

Packaging: Packed in bundles with standard export sea-worthy package or as customer require

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: How many types of bearing steel that OKorder.com can supply?

A4: Two types, carbon spring steel and alloy spring steel

Images:

- Q: Can special steel be used in the power transmission industry?

- Yes, special steel can be used in the power transmission industry. Special steel alloys offer enhanced strength, durability, and resistance to wear and corrosion, making them suitable for various components in power transmission equipment such as gears, shafts, bearings, and connectors. These alloys can withstand high loads, extreme temperatures, and harsh environmental conditions, ensuring reliable performance and longevity in power transmission applications.

- Q: What are the main applications of special steel in the power storage industry?

- Special steel is widely used in the power storage industry for various applications. One of the main applications is in the manufacturing of battery components, where special steel is used to produce high-quality casings and connectors that ensure the safety and reliability of the batteries. Special steel is also utilized in the construction of power storage infrastructure, such as steel frames and supports for battery racks. Additionally, special steel is used in the production of power storage system components, like turbine blades, rotors, and stators, which are essential for efficient energy generation and storage. Overall, special steel plays a vital role in enhancing the performance, durability, and safety of power storage systems in the industry.

- Q: What are the specific requirements for special steel used in the textile industry?

- The primary focus when considering the specific needs of special steel used in the textile industry lies in its durability, corrosion resistance, and heat resistance. To maintain its structural integrity, the steel must withstand the harsh conditions and high temperatures involved in textile processing. Firstly, it is essential for the steel used in the textile industry to possess exceptional durability. It must be capable of enduring significant mechanical stress, such as tension, compression, and bending, without experiencing any deformation or breakage. This is crucial due to the constant movement and repetitive actions of the machinery in the textile industry. Another vital requirement is corrosion resistance. The steel must be able to resist corrosion caused by chemicals, moisture, and other environmental factors. This is particularly important as textile manufacturing processes frequently involve the use of various chemicals and water. Heat resistance is also a crucial factor to consider when selecting special steel for the textile industry. Since manufacturing processes involve high temperatures, the steel must be able to withstand and maintain its strength and properties under these conditions. This ensures the longevity and efficiency of the equipment and machinery used in textile production. Additionally, the steel used in the textile industry should exhibit excellent machinability. It should be easy to cut, shape, and form into various components and parts required for textile machinery. This allows for efficient manufacturing and customization of equipment to meet specific needs. Furthermore, the steel may also be required to meet specific standards and certifications established by regulatory bodies or industry organizations. This ensures that the steel meets the necessary quality and safety requirements. For example, it may need to comply with international standards like ISO 9001 for quality management systems. To summarize, the special steel used in the textile industry must meet requirements for durability, corrosion resistance, heat resistance, machinability, and compliance with relevant standards. Meeting these criteria ensures that the steel can withstand the demanding conditions of textile manufacturing and contribute to the efficiency and reliability of the machinery involved.

- Q: How does special steel contribute to the energy aftermarket industry?

- Special steel contributes to the energy aftermarket industry by providing high-quality and durable materials that are essential for the manufacturing of various energy-related components. It is used in the production of turbines, generators, pipelines, and other critical equipment, ensuring optimal performance and longevity in energy production and distribution. The special properties of this steel, such as corrosion resistance, high temperature resistance, and strength, make it an ideal choice for demanding applications in the energy sector. Its availability and usage in the industry contribute to enhanced efficiency, reliability, and overall sustainability in the energy aftermarket.

- Q: What are the different chemical resistance grades of special steel?

- Special steels, often referred to as stainless steels, are known for their excellent resistance to corrosion and chemical attack. They are a group of alloys that contain a high proportion of chromium, which forms a protective oxide layer on the surface, preventing further corrosion. The resistance of special steel to various chemicals can vary depending on the specific grade or alloy composition. Here are some of the common chemical resistance grades of special steel: 1. Austenitic Stainless Steel: This is the most common type of stainless steel and offers excellent resistance to a wide range of chemicals, including organic acids, alkalis, and salts. The most widely used grade within this group is 304 stainless steel. 2. Ferritic Stainless Steel: Ferritic stainless steels have lower corrosion resistance compared to austenitic grades but still offer good resistance to many chemicals. They are particularly resistant to nitric acid and some organic acids. Grade 430 stainless steel is a common example of ferritic stainless steel. 3. Martensitic Stainless Steel: Martensitic stainless steels are known for their high strength and hardness. While they have lower corrosion resistance compared to austenitic and ferritic grades, they can still exhibit good resistance to certain chemicals, especially in mildly corrosive environments. 4. Duplex Stainless Steel: This type of stainless steel combines the properties of both austenitic and ferritic grades, providing enhanced strength and improved resistance to stress corrosion cracking. Duplex stainless steels offer excellent resistance to a wide range of chemicals, including organic acids, chloride-containing solutions, and saltwater. 5. Precipitation-Hardening Stainless Steel: These steels can be heat-treated to achieve high strength and corrosion resistance. They are typically resistant to a wide range of chemicals, including organic acids, alkalis, and some organic solvents. It's important to note that the chemical resistance of any steel grade can also be influenced by factors such as temperature, concentration of the chemical, and the presence of other corrosive agents. Therefore, it is advisable to consult the manufacturer's specifications or seek expert advice when selecting a special steel grade for specific chemical resistance requirements.

- Q: How is special steel used in the manufacturing of bearings?

- Due to its unique properties, special steel is utilized in the production of bearings, which are vital components employed in various industries. These bearings serve the purpose of reducing friction between moving parts, promoting smooth motion, and supporting heavy loads. The utilization of special steel guarantees exceptional performance and longevity. For the production of bearings, the preferred choice of special steel includes stainless steel and high-carbon chromium steel. This selection is based on the remarkable strength, hardness, and resistance to corrosion that these types of steel possess. These properties enable the bearings to endure heavy loads, withstand wear and tear, and operate effectively in challenging environments. The manufacturing process for bearings involves shaping and heat treatment. Initially, special steel is melted and cast into the desired form, typically a ring or a ball. Subsequently, the steel undergoes various heat treatment procedures like annealing, quenching, and tempering to enhance its hardness, toughness, and overall mechanical properties. This heat treatment ensures that the steel is adequately hardened to endure the stress and friction it will encounter during operation. Once the steel has undergone appropriate heat treatment, it is machined and ground to attain precise dimensions and smooth surfaces. This step is vital to ensure that the bearings possess the necessary tolerance and can rotate smoothly without any interference. Special steel's machinability and grindability simplify the achievement of the required accuracy and surface finish. Following the machining process, the bearings can be assembled with other components and lubricated to ensure proper lubrication and minimize friction. Special steel's corrosion resistance is particularly valuable at this stage as it shields the bearings from rust and degradation caused by moisture or aggressive environments. In conclusion, special steel is chosen for the production of bearings due to its exceptional strength, hardness, and corrosion resistance. These properties enable the bearings to withstand heavy loads, resist wear, and function effectively in challenging conditions. With the aid of its excellent machinability and grindability, special steel guarantees the attainment of the necessary precision and surface finish. Overall, special steel plays a pivotal role in the production of high-quality bearings that enable efficient and reliable motion in various industries.

- Q: How does special steel contribute to the ductility of products?

- Special steel's ability to enhance the ductility of products is attributed to its distinct composition and manufacturing techniques. Ductility refers to a material's capacity to deform under stress without fracturing or breaking. In the case of special steel, its composition incorporates specific alloying elements that bolster its ductility. One way in which special steel augments ductility is by reducing the presence of impurities. Stringent quality control measures are employed during the production of special steel to ensure that impurities like sulfur and phosphorus are kept at minimal levels. These impurities have the potential to render steel brittle, thereby diminishing its ductility. By minimizing their presence, special steel retains its ability to deform without failure. Moreover, special steel often contains particular alloying elements such as nickel, chromium, and molybdenum. These alloying elements play a critical role in enhancing ductility. For instance, nickel enhances the toughness and ductility of steel by increasing its capacity to absorb energy before fracturing. On the other hand, chromium enhances the steel's resistance to corrosion and oxidation, thereby safeguarding its ductility. The manufacturing processes employed in producing special steel also contribute to its ductility. Precise temperature control during the heat treatment of special steel can optimize its microstructure, resulting in improved ductility. Additionally, special steel can undergo various forming processes, such as hot or cold rolling, which further refine its microstructure and augment its ductility. In conclusion, special steel's unique composition, minimal impurity levels, inclusion of specific alloying elements, and meticulous manufacturing processes significantly contribute to its ductility. Consequently, it is an excellent choice for applications that require deformation without failure, such as automotive components, machinery parts, and structural applications.

- Q: What are the properties of nitriding steel?

- Nitriding steel is a process in which the surface of the steel is hardened and enhanced by introducing nitrogen into its structure. The properties of nitriding steel include increased surface hardness, improved wear resistance, enhanced fatigue strength, and greater corrosion resistance. Additionally, nitriding steel exhibits a low coefficient of friction, excellent dimensional stability, and increased resistance to heat and oxidation.

- Q: What are the environmental considerations associated with special steel production?

- The production of special steel entails various environmental factors to consider due to its resource-intensive nature and the emissions produced throughout the manufacturing process. One primary environmental factor associated with special steel production involves the extraction of raw materials. The production of special steel necessitates specific alloys and additives, typically requiring the extraction of rare or valuable metals. The mining of these materials can result in significant environmental consequences, such as habitat destruction, soil erosion, water pollution, and the release of toxic substances. Another factor to consider is the energy consumption during the production process. Special steel production includes energy-intensive stages like melting, refining, and shaping. These processes frequently rely on fossil fuels, contributing to greenhouse gas emissions and air pollution. Moreover, the high temperatures required for steel production result in substantial carbon dioxide emissions, a leading cause of climate change. Water usage also poses a concern in special steel production. The production process demands a substantial quantity of water for cooling, cleaning, and lubrication. If not managed appropriately, this can lead to water scarcity and pollution. The effluents produced during production may contain heavy metals, acids, and other pollutants, capable of harming aquatic ecosystems if not adequately treated. Waste generation is another environmental aspect to consider. Special steel production generates various types of waste, including slag, dust, and sludge. These waste materials may contain heavy metals, toxins, and other pollutants. Proper disposal or treatment of these wastes is crucial to prevent pollution of soil, water, and air. Lastly, the transportation of raw materials and finished products in special steel production can contribute to carbon emissions and air pollution. The long-distance shipping of raw materials and finished steel products adds to the overall environmental impact of the industry. In conclusion, special steel production presents numerous environmental considerations, including raw material extraction, energy consumption, water usage, waste generation, and transportation. To mitigate these impacts, companies should prioritize sustainable sourcing of raw materials, invest in energy-efficient technologies, promote water conservation and treatment practices, manage and minimize waste generation, and explore cleaner transportation options.

- Q: What are the different methods for tempering special steel?

- There are different methods available for tempering special steel, each having its own advantages and considerations. Some commonly used methods for tempering special steel are: 1. Air Tempering: Special steel is heated to a specific temperature and allowed to cool in still air. This method is suitable for low alloy steels and results in uniform hardness throughout the steel. 2. Oil Tempering: Special steel is heated to a specific temperature and then rapidly cooled by quenching it in oil. This method is commonly used for tool steels as it provides a good balance between hardness and toughness. 3. Water Tempering: Similar to oil tempering, this method involves quenching the steel in water after heating it to a specific temperature. It leads to a harder steel due to faster cooling, but it may also increase brittleness. 4. Salt Bath Tempering: The steel is immersed in a molten salt bath at a specific temperature. This method ensures controlled and uniform heat transfer, resulting in consistent hardness throughout the steel. 5. Cryogenic Tempering: Steel is cooled to extremely low temperatures, often below -100°C (-148°F), using liquid nitrogen or helium. This method further reduces residual stresses and enhances wear resistance of the steel. It is important to consider various factors such as the type of steel, desired hardness, intended application, and the required balance between hardness and toughness when choosing a specific tempering method for special steel. Following proper heat treatment guidelines and seeking advice from experts is crucial to achieve optimal results for a particular steel alloy.

Send your message to us

Hot Rolled Spring Steel Round Bar 16mm with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords