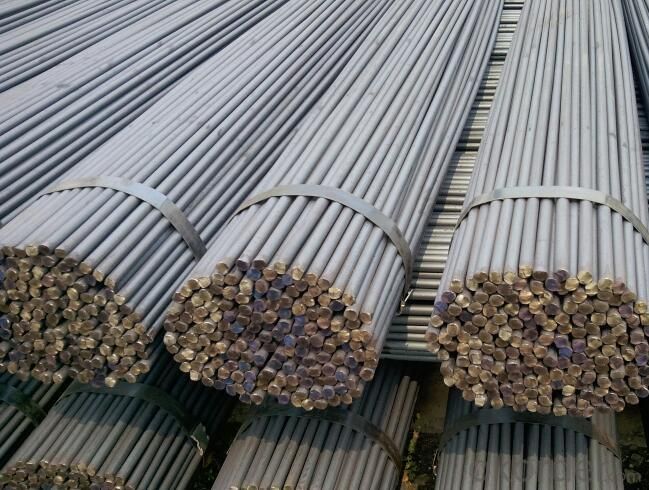

Prime Hot Rolled Low Carbon Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Prime Hot Rolled Low Carbon Steel Round Bar at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Prime Hot Rolled Low Carbon Steel Round Bar are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Prime Hot Rolled Low Carbon Steel Round Bar are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

| ROUND BAR | |

| SIZE d(mm) | theoretical kg/m |

| 5.5 | 0.186 |

| 6 | 0.222 |

| 7 | 0.302 |

| 8 | 0.395 |

| 9 | 0.499 |

| 10 | 0.617 |

| 11 | 0.746 |

| 12 | 0.888 |

| 13 | 1.04 |

| 14 | 1.21 |

| 15 | 1.39 |

| 16 | 1.58 |

| 17 | 1.78 |

| 18 | 2 |

| 19 | 2.23 |

| 20 | 2.47 |

| 21 | 2.72 |

| 22 | 2.98 |

| 24 | 3.55 |

| 25 | 3.85 |

| 26 | 4.17 |

| 28 | 4.83 |

| 30 | 5.55 |

| 32 | 6.31 |

| 34 | 7.13 |

| 36 | 7.99 |

| 38 | 8.9 |

| 40 | 9.86 |

| 42 | 10.9 |

| 45 | 12.5 |

| 48 | 14.2 |

| 50 | 15.4 |

| 53 | 17.3 |

| 56 | 19.3 |

| 60 | 22.2 |

| 63 | 24.5 |

| 65 | 26 |

| 70 | 30.2 |

| 75 | 34.7 |

| 80 | 39.5 |

| 85 | 44.5 |

| 90 | 49.9 |

| 95 | 55.6 |

| 100 | 61.7 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: what is the difference between actual weight and theoretical weight?

A2: All the section steel has two weights: actual weight and theoretical weight. Actual weight is the weighing out when the product delivered from the mill. Theoretical weight is calculated by pieces. The invoice can be based on each of them as your request

Q3: How many tons of steel products could be loaded in containers?

A3: Usually the steel products are delivered by bulk vessel because of the large quantity and the freight. However, there are no bulk vessel enter some seaports so that we have to deliver the cargo by containers. The 6m steel product can be loaded in 20FT container, but the quantity is changed according to the size, usually from 18tons to 25tons.

Images:

- Q: Can steel round bars be used for making gears or sprockets?

- Gears or sprockets can indeed be made using steel round bars. Steel is widely employed in the manufacturing of gears and sprockets due to its exceptional strength, durability, and resistance to wear and tear. Steel round bars can be shaped through machining or forging and then further modified by cutting, drilling, or milling to create the necessary teeth or grooves for gear or sprocket functionality. The selection of the specific type of steel and its heat treatment can be based on the application requirements, such as load capacity, speed, and environmental conditions. All in all, steel round bars offer a versatile and dependable option for the production of gears and sprockets.

- Q: What is the standard length of a steel round bar?

- The standard length of a steel round bar can differ based on the specific industry and its intended usage. Nevertheless, in most cases, a steel round bar typically measures 20 feet or 6 meters. This particular length finds extensive application in construction, manufacturing, and engineering sectors. It is worth mentioning that custom lengths can also be acquired to align with the specific needs of a project or application.

- Q: Can steel round bars be used for making steering linkages?

- Yes, steel round bars can be used for making steering linkages. Steel round bars are commonly used in various applications, including automotive and mechanical engineering, due to their high strength, durability, and resistance to wear and tear. Steering linkages are critical components in a vehicle's steering system, responsible for transmitting steering input from the steering wheel to the wheels. The use of steel round bars provides the necessary strength and rigidity required to ensure efficient and reliable steering performance. However, it is important to consider other factors such as the specific design requirements, weight considerations, and the desired level of flexibility or torsional properties when selecting the appropriate type and size of steel round bar for steering linkages.

- Q: What are the typical dimensions of a steel round bar?

- The dimensions of a steel round bar can vary depending on the specific application and industry requirements. Generally, diameter sizes for steel round bars range from 1/4 inch to 24 inches. These sizes are often measured in increments of 1/8 inch or 1/4 inch. The length of a steel round bar is usually standardized at 20 feet, although shorter lengths may also be available. It is important to consider that these dimensions can significantly differ based on the grade and type of steel used, as well as the manufacturing process. Therefore, it is crucial to refer to the appropriate industry standards or consult a supplier for precise dimensions required for a particular project.

- Q: How do you measure the length of a steel round bar?

- To measure the length of a steel round bar, you can use a measuring tape or a ruler. Simply place one end of the measuring tool at the starting point of the bar, and extend it until you reach the other end. Ensure that the measuring tool is aligned correctly with the bar for an accurate measurement.

- Q: Can steel round bars be coated or painted?

- Yes, steel round bars can be coated or painted. Coating or painting steel round bars can provide protection against corrosion, enhance aesthetics, and improve durability.

- Q: What are the different types of steel round bar alloys for improved toughness and wear resistance?

- Improved toughness and wear resistance are key characteristics in several steel round bar alloys. These alloys are essential in applications where strength and durability are necessary. Some of the commonly utilized alloys are: 1. Alloy Steel: By incorporating elements like chromium, nickel, molybdenum, or vanadium, alloy steel round bars are fabricated to enhance their mechanical properties. These alloys provide increased strength, toughness, and wear resistance. 2. Stainless Steel: With a minimum chromium content of 10.5%, stainless steel round bars are corrosion-resistant alloys. They exhibit excellent toughness, high strength, and superior wear resistance. Industries such as aerospace, automotive, and construction widely rely on stainless steel round bars. 3. Tool Steel: Tool steel round bars are tailor-made for applications that demand high wear resistance and toughness. These alloys are commonly employed in the manufacturing of cutting tools, dies, and molds. By incorporating elements like tungsten, vanadium, or molybdenum, tool steel alloys improve hardness and wear resistance. 4. Carbon Steel: Renowned for their high strength and toughness, carbon steel round bars find extensive use. These alloys contain varying amounts of carbon and are recognized for their excellent wear resistance. Industries including manufacturing, construction, and automotive utilize carbon steel round bars. 5. Bearing Steel: Bearing steel round bars are specifically engineered to withstand high stress and offer excellent wear resistance. These alloys are commonly employed in the production of ball bearings, roller bearings, and other high-performance bearing components. Bearing steel alloys typically include elements like chromium, silicon, and manganese to enhance mechanical properties. To conclude, a range of steel round bar alloys is available, each offering improved toughness and wear resistance. The selection of the most suitable alloy depends on specific application requirements and desired mechanical properties.

- Q: What are the advantages of using tin-alloy steel round bars?

- Tin-alloy steel round bars offer several benefits in various industries: 1. Corrosion Resistance: Due to the presence of tin, these bars have exceptional resistance to corrosion. They are suitable for industries exposed to moisture, chemicals, or harsh environments like marine, automotive, and construction. 2. Enhanced Machinability: Tin-alloy steel round bars are known for their superior machinability. The addition of tin makes them easier to cut, drill, and shape, reducing tool wear and increasing productivity during machining. 3. Strength and Durability: By alloying tin with steel, these bars become stronger and more durable. They have higher tensile strength and hardness compared to regular steel bars, making them resistant to wear, deformation, and fatigue. This ensures longevity and suitability for heavy-duty applications. 4. Efficient Heat Transfer: Tin-alloy steel round bars exhibit excellent thermal conductivity. They are ideal for applications that require efficient heat transfer, such as heat exchangers, radiators, and engine components. 5. Reduced Friction: Compared to regular steel bars, tin-alloy steel round bars have a lower friction coefficient. This makes them suitable for applications where minimizing friction is crucial, like bearings, shafts, and gears. It results in reduced energy consumption and increased operational efficiency. 6. Cost-Effective Alternative: Tin-alloy steel round bars offer a cost-effective alternative to pricier materials like stainless steel or brass. They provide similar performance characteristics at a lower price point, making them a viable choice for various applications without compromising on quality. In conclusion, the advantages of using tin-alloy steel round bars include corrosion resistance, improved machinability, strength and durability, efficient heat transfer, reduced friction, and cost-effectiveness. These properties make them versatile and reliable for diverse applications across different industries.

- Q: Can steel round bars be used in the fabrication of machinery?

- Yes, steel round bars can be used in the fabrication of machinery. Steel round bars are often chosen for their high strength and durability, making them suitable for various applications in machinery fabrication. Additionally, their uniform shape and ease of machining make them versatile for use in different components and structures of machinery.

- Q: What are the different types of steel round bar coatings used in the automotive industry?

- There are several different types of steel round bar coatings used in the automotive industry, including galvanized coatings, epoxy coatings, and powder coatings. These coatings are applied to the steel bars to provide protection against corrosion, enhance durability, and improve the overall appearance of the automotive components.

Send your message to us

Prime Hot Rolled Low Carbon Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords