Hot Rolled Prime Low Carbon Steel Round Bar High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

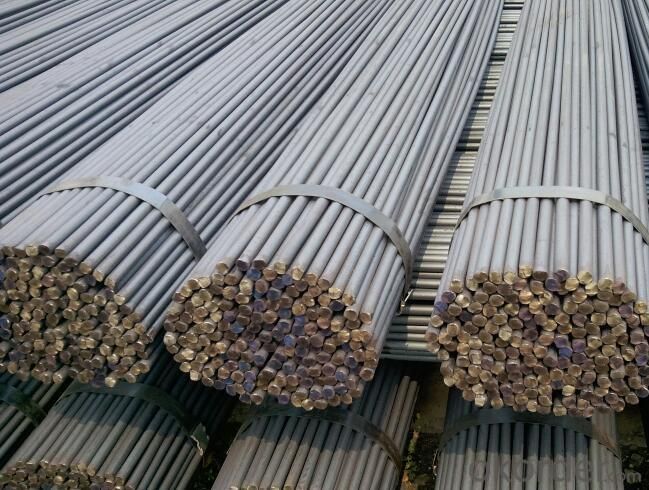

Hot Rolled Prime Low Carbon Steel Round Bar

Product Description:

OKorder is offering Hot Rolled Prime Low Carbon Steel Round Bar at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Prime Low Carbon Steel Round Bar are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Hot Rolled Prime Low Carbon Steel Round Bar are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

ROUND BAR | |

SIZE | theoretical |

5.5 | 0.186 |

6 | 0.222 |

7 | 0.302 |

8 | 0.395 |

9 | 0.499 |

10 | 0.617 |

11 | 0.746 |

12 | 0.888 |

13 | 1.04 |

14 | 1.21 |

15 | 1.39 |

16 | 1.58 |

17 | 1.78 |

18 | 2 |

19 | 2.23 |

20 | 2.47 |

21 | 2.72 |

22 | 2.98 |

24 | 3.55 |

25 | 3.85 |

26 | 4.17 |

28 | 4.83 |

30 | 5.55 |

32 | 6.31 |

34 | 7.13 |

36 | 7.99 |

38 | 8.9 |

40 | 9.86 |

42 | 10.9 |

45 | 12.5 |

48 | 14.2 |

50 | 15.4 |

53 | 17.3 |

56 | 19.3 |

60 | 22.2 |

63 | 24.5 |

65 | 26 |

70 | 30.2 |

75 | 34.7 |

80 | 39.5 |

85 | 44.5 |

90 | 49.9 |

95 | 55.6 |

100 | 61.7 |

- Q: What are the advantages of using titanium-alloy steel round bars?

- There are several advantages of using titanium-alloy steel round bars: 1. High strength: Titanium-alloy steel round bars have exceptional strength-to-weight ratio, making them ideal for applications where strength is crucial. Their high tensile strength allows them to withstand heavy loads and resist deformation. 2. Corrosion resistance: Titanium-alloy steel round bars exhibit excellent corrosion resistance, even in highly corrosive environments. This property makes them suitable for marine, aerospace, and chemical industries, where exposure to saltwater or chemicals is common. 3. Lightweight: Compared to other metal alloys, titanium-alloy steel round bars are relatively lightweight. This characteristic makes them advantageous in applications where weight reduction is important, such as in aerospace and automotive industries, as it allows for better fuel efficiency and increased payload capacity. 4. High temperature resistance: Titanium-alloy steel round bars can withstand high temperatures without losing their structural integrity. This property makes them suitable for applications in high-temperature environments, such as in power generation and oil and gas industries. 5. Biocompatibility: Titanium is a biocompatible material, meaning it is well-tolerated by the human body and does not cause adverse reactions. This makes titanium-alloy steel round bars suitable for medical implants, such as orthopedic implants and dental fixtures, where biocompatibility is critical. 6. Excellent fatigue resistance: Titanium-alloy steel round bars have exceptional fatigue resistance, which means they can withstand repeated loading and unloading without experiencing fatigue failure. This property makes them suitable for applications that require long-term durability and reliability, such as in structural components and machinery. Overall, the advantages of using titanium-alloy steel round bars lie in their high strength, corrosion resistance, lightweight nature, high temperature resistance, biocompatibility, and excellent fatigue resistance. These properties make them a versatile choice for various industries, ranging from aerospace and automotive to medical and petrochemical sectors.

- Q: What are the different grades of alloy steel round bars for automotive applications?

- There are several different grades of alloy steel round bars used for automotive applications, including 4140, 4340, and 8620. These grades offer varying levels of strength, toughness, and wear resistance, allowing them to be used in different automotive components such as shafts, gears, and axles. The choice of grade depends on the specific requirements of the application, taking into consideration factors like load capacity, durability, and cost.

- Q: Can steel round bars be threaded?

- Steel round bars have the capability to be threaded, which involves cutting threads onto the surface of the cylindrical object in order to create a screw-like shape. This enables the bar to be securely fastened into a corresponding threaded hole or to be joined with another threaded component. Threading can be accomplished through various methods, such as manual threading with a die or by employing machine tools like lathes or thread rolling machines. The specific technique utilized depends on the desired thread size and type. However, it is vital to recognize that not all steel round bars are compatible with threading, as the steel's material composition and hardness can impact the threading process. As a result, it is advisable to seek guidance from a professional or someone experienced to ensure the steel round bar is appropriate for threading and to determine the most suitable threading approach.

- Q: Can steel bars be replaced by large screws in the concrete floor?

- Tensile strength, extensibility, yield point! The same thread can be used instead!Of course, the number of roots must also be the same ~ only specifications vary!

- Q: What are the advantages of using nickel-tungsten alloy steel round bars?

- There are several advantages to using nickel-tungsten alloy steel round bars. Firstly, the inclusion of nickel enhances the corrosion resistance of the bars, making them suitable for use in harsh environments. Additionally, the addition of tungsten improves the strength and hardness of the bars, making them highly durable and able to withstand heavy loads and high temperatures. Furthermore, the alloy steel composition provides excellent wear resistance, making these bars ideal for applications that require prolonged use or frequent contact with abrasive materials. Overall, nickel-tungsten alloy steel round bars offer a combination of corrosion resistance, strength, and durability, making them a reliable choice for various industrial applications.

- Q: What are the different types of surface treatments for steel round bars?

- Steel round bars can be treated in several ways to enhance their properties and suit different applications. Some commonly used treatments for steel round bars include: 1. Zinc coating, also known as galvanization, provides excellent corrosion resistance. It is often used in outdoor and marine applications. 2. Black oxide coating chemically converts the surface of the steel round bars to a black iron oxide layer, offering enhanced corrosion resistance and an attractive black finish. This treatment is popular for decorative purposes. 3. Grinding is a surface treatment that involves using abrasive materials to remove the outer layer of the steel round bars. This process improves the surface finish, making them smoother and more visually appealing. 4. Shot blasting involves propelling small metallic or non-metallic particles at high velocity onto the surface of the steel round bars. It effectively removes impurities like mill scale and rust, resulting in a clean and uniform surface. 5. Chrome plating deposits a layer of chromium onto the surface of the steel round bars, providing excellent corrosion resistance and a polished, mirror-like finish. This treatment is commonly used when aesthetics and corrosion resistance are important. 6. Powder coating involves applying a dry powder electrostatically to the steel round bars, which is then cured under heat. This treatment creates a durable and visually appealing finish that is resistant to corrosion, chemicals, and UV rays. 7. Passivation is a chemical treatment that removes iron and other contaminants from the surface of the steel round bars. It leaves behind a clean and corrosion-resistant layer. Passivation is particularly important in industries such as medical and food, where cleanliness and corrosion resistance are crucial. These examples highlight the range of surface treatments available for steel round bars. The choice of treatment depends on specific requirements such as corrosion resistance, aesthetics, and durability.

- Q: How do you calculate the weight of a steel round bar based on its volume and density?

- To determine the weight of a steel round bar based on its volume and density, one can utilize the following formula: Weight = Volume x Density Initially, ascertain the volume of the round bar. The volume of a cylinder, which represents the shape of a round bar, can be computed using the subsequent equation: Volume = π x (diameter/2)^2 x length Here, π denotes a mathematical constant that is roughly equivalent to 3.14159, and the diameter and length are the measurements of the round bar. Once the volume is determined, it is necessary to know the density of the steel. The density of steel may differ depending on the type and grade of steel employed. Typically, density is measured in kilograms per cubic meter (kg/m^3) or pounds per cubic inch (lbs/in^3). The density of steel can be found in reference materials or on the internet. Ultimately, the volume should be multiplied by the density to acquire the weight of the steel round bar. Ensure that the units of volume and density are consistent. For instance, if the volume is given in cubic inches and the density is in pounds per cubic inch, the weight will be expressed in pounds. Conversely, if the volume is in cubic meters and the density is in kilograms per cubic meter, the weight will be in kilograms. It is essential to note that this calculation assumes that the round bar is entirely composed of steel and possesses a uniform density throughout its volume. Moreover, this calculation disregards any other factors that may influence the weight, such as impurities or surface finish.

- Q: What are the different machining processes used for steel round bars?

- There are several machining processes commonly used for steel round bars, depending on the desired outcome and specifications of the project. Some of the most common machining processes for steel round bars include: 1. Turning: Turning is a machining process where the round bar is rotated and a cutting tool is used to remove material, creating a desired shape or size. This process is commonly used to reduce the diameter of the round bar or to create precision cylindrical shapes. 2. Drilling: Drilling involves creating holes in the steel round bar using a rotating cutting tool called a drill bit. This process is often used to create holes for bolts, screws, or other fasteners. 3. Milling: Milling is a machining process that involves removing material from the surface of the steel round bar using a rotating cutting tool with multiple teeth. This process is used to create flat surfaces, grooves, or complex shapes on the round bar. 4. Grinding: Grinding is a process where abrasive particles are used to remove material from the steel round bar, creating a smooth surface finish or achieving specific tolerances. It is commonly used to refine the surface finish or to remove any imperfections. 5. Thread rolling: Thread rolling is a process used to create external threads on the steel round bar. A hardened steel die is pressed against the rotating round bar, causing the material to flow and form the desired threads. 6. Cold drawing: Cold drawing is a process where the steel round bar is pulled through a die to reduce its diameter and improve its surface finish. This process is used to create precise dimensions and improve the mechanical properties of the steel round bar. 7. Heat treatment: Heat treatment is not a machining process itself, but it is often used in conjunction with machining to enhance the properties of the steel round bar. Heat treatment processes such as annealing, quenching, and tempering can be used to improve hardness, strength, and toughness. These are just a few of the many machining processes that can be used for steel round bars. The specific process chosen will depend on factors such as the desired shape, size, surface finish, and mechanical properties required for the application.

- Q: How do you prevent scaling of steel round bars during heat treatment?

- To minimize scaling of steel round bars during heat treatment, various steps can be taken: 1. Employ a protective atmosphere: Heat treatment can be conducted in a controlled gas environment, such as a furnace with regulated gas composition. This shields the steel bars from oxygen exposure, the main cause of scaling. 2. Employ a protective coating: Coating the steel round bars with a substance like refractory material or a thin layer of paint can help prevent scaling. This creates a barrier between the steel and the oxygen in the atmosphere, reducing the likelihood of scaling. 3. Use a reducing atmosphere: Instead of a regular atmospheric environment, heat treatment can be carried out in a reducing atmosphere. This involves introducing gases like hydrogen or nitrogen into the furnace, reacting with oxygen to create a controlled environment that prevents scaling. 4. Control the heating rate: Rapid heating can lead to increased scaling due to sudden exposure to high temperatures. By controlling the heating rate, such as gradually increasing temperature, scaling can be minimized. 5. Limit the exposure time: Reducing the duration that steel round bars are exposed to high temperatures helps prevent scaling. This can be achieved by optimizing the heat treatment process and avoiding prolonged exposure to elevated temperatures. 6. Clean the surface before heat treatment: Before heat treatment, it is essential to remove any contaminants or residues from the surface of the steel round bars. This can be achieved through mechanical methods like wire brushing or chemical cleaning techniques, ensuring a clean surface that is less prone to scaling. Implementing these preventive measures effectively minimizes scaling of steel round bars during heat treatment, resulting in improved quality and performance of the treated bars.

- Q: What are the advantages of using low-alloy steel round bars?

- One advantage of using low-alloy steel round bars is its increased strength and durability compared to regular carbon steel. This makes it suitable for applications that require high tensile strength and resistance to wear and tear. Additionally, low-alloy steel round bars generally offer better weldability and machinability, allowing for easier fabrication and modification. Overall, low-alloy steel round bars provide a cost-effective solution for various industries, including construction, automotive, and manufacturing.

Send your message to us

Hot Rolled Prime Low Carbon Steel Round Bar High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords