Hot/Cold Rolled Steel Coil Chinese Supplier Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

1.Commodity: hot rolled steel coil, SPHC.

2.Executive Standards: GB,ASTM,JIS,EN,IS

3.Delivery condition: hot rolled or annealed

4.Delivery time: within 30days after L/C or T/T deposit

5.Specification:

thickness 1-4mm

width 800-1600mm

6.Coil weight: 2.5-3mt

7.Packing method: bundled with steel strip

8.Payment terms: 100%L/C at sight or 30%T/T deposit +70%balance against B/L copy.

9.MOQ: 50mt for single size

10.Chemical compostion

| Steel Grade | C % | Mn % | Si % | S % | P % |

| Q235 | 0.12-0.22 | 0.30-0.60 | 0.30 Max. | 0.04 Max. | 0.04 Max. |

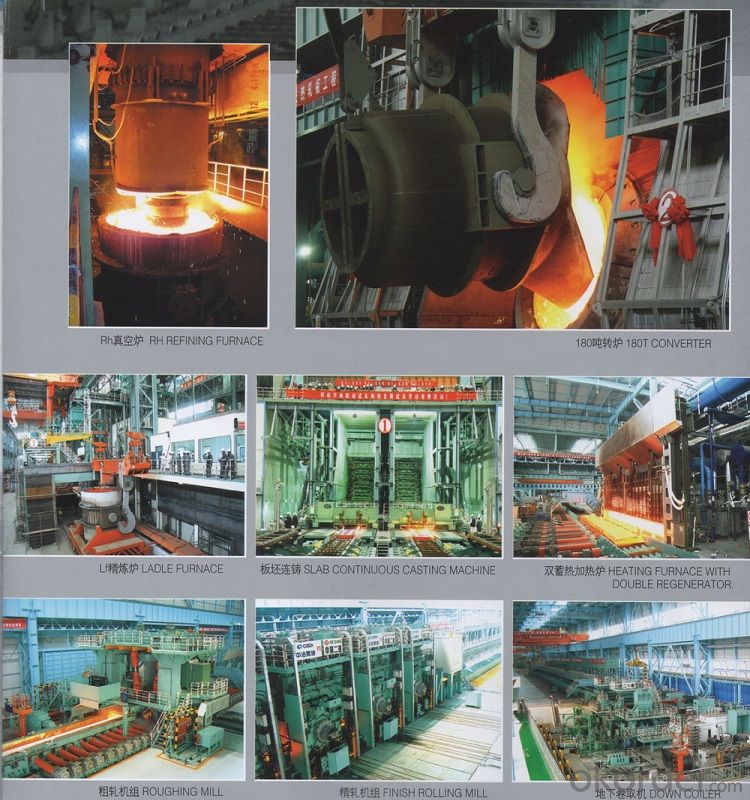

Product Image:

Production Process:

FAQ

1. Q: What's the MOQ?

A: Our MOQ is 25mt.

2. Q: What's the delivery time?

A: It will take about 30 days after TT or L/C.

3. Q: What is the payment terms?

A: T/T, L/C at sight

4. Q: How does your factory carry out quality control?

A: We attach great importance to quality control.Every part of our products has its own QC.

5. Q: What certificate do you have?

A: We have SGS, ISO9001 etc. Also we can apply any certificate if you need if the qty is OK.

- Q: How do steel coils impact the environment?

- Steel coils can have significant environmental impacts throughout their lifecycle. The production of steel coils involves extracting and processing raw materials, which can result in deforestation, habitat destruction, and air and water pollution. Additionally, the energy-intensive manufacturing process contributes to greenhouse gas emissions. Improper disposal or recycling of steel coils can further exacerbate environmental harm. Overall, the environmental impact of steel coils underscores the need for sustainable production practices and responsible end-of-life management.

- Q: What are the different methods of transporting steel coils?

- Depending on factors such as weight, size, and distance, there are various methods available for transporting steel coils. These include: 1. Flatbed trucks: Steel coils can be transported on flatbed trucks, which have a spacious open platform for easy loading and unloading. This option is commonly used for shipments of short to medium distances and provides convenient access to the coils. 2. Rail transport: Steel coils can also be transported by rail using specialized coil cars with curved interiors to securely hold the coils. Rail transport is often preferred for long-distance shipments due to its cost-effectiveness and capacity to handle large quantities. 3. Shipping containers: Steel coils can be loaded into shipping containers for transportation via sea or inland waterways. To prevent movement during transit, the coils are usually secured inside the container using bracing or blocking materials. This method is commonly employed for international shipments and facilitates easy handling and transfer between different modes of transportation. 4. Barges: In some cases, steel coils can be transported on barges along rivers, canals, or other inland waterways. Barges are particularly suitable for large and heavy shipments, offering a cost-effective and efficient means of transportation. 5. Roll-on/roll-off (RoRo) vessels: RoRo vessels are specialized ships designed to transport vehicles and large cargo that can be rolled on and off the ship. Steel coils can be loaded onto trailers or flatbeds and driven onto the vessel, providing a convenient transportation option. 6. Air freight: Although less common due to higher costs, steel coils can also be transported by air. This method is typically used for urgent and time-sensitive shipments or when the distance is too great for other modes of transportation. Air freight offers the advantage of speed and can be a viable option in certain situations. In conclusion, the choice of transportation method for steel coils depends on factors such as cost, distance, time frame, and logistical requirements. Freight forwarders and logistics providers can assist in determining the most suitable method for a specific shipment.

- Q: The strip tower height

- Defects: cold-rolled steel sheet (coil)

- Q: a picture of the atomic structure of carbon steel

- This is actually a quite complex question... The atomic arrangement in steels can be controlled over a pretty wide range of different structures. This is really the fundamental reason why steel is such a commonly used material. The different atomic structures produce different physical properties so metallurgists have developed many different processes to control the atomic structure to get the properties they want. One simple answer is that Fe is BCC, body centered cubic at room temperature at equilibrium conditions. When you heat Fe up, it transforms to FCC, face centered cubic. If you continue heating Fe, it goes back to BCC, then it melts. The addition of C makes these structures (and the transformation temperatures) different. Deviating from equilibrium conditions by, for example, cooling very quickly (quenching) creates different atomic structures (one of the most important is known as martensite). Depending on how much C is in the steel, you can also have two different atomic structures (two different phases) present in equilibirum, for example, pearlite which is a mix of alpha Fe (BCC) and iron carbide Fe3C (orthorombic crystal structure). So... you need to think a little more about exactly what you want a picture of. I hope this helps

- Q: What are the different types of steel coil storage methods?

- There are several types of steel coil storage methods, including stacking coils vertically, using coil cradles or saddles, utilizing coil racks or frames, employing coil lifters or C-hooks, and implementing automated coil storage systems. Each method is designed to accommodate different storage requirements and ensure the safety and efficient handling of steel coils.

- Q: How are steel coils used in the manufacturing of electrical appliances?

- Steel coils are used in the manufacturing of electrical appliances primarily for their magnetic properties. These coils are wound around a core to create electromagnets, which are essential components in various appliances like transformers, motors, generators, and solenoids. The magnetic field generated by the steel coils allows for the efficient conversion of electrical energy into mechanical energy or vice versa, enabling the proper functioning of these appliances.

- Q: What are the common welding techniques used for steel coils?

- Steel coils can be welded using different techniques, such as shielded metal arc welding (SMAW), gas metal arc welding (GMAW), and flux-cored arc welding (FCAW). SMAW, also known as stick welding, involves creating an arc between the welding electrode and the base material using an electric current. The electrode is coated with flux, which shields the weld from atmospheric contamination. This versatile technique can be used for both thick and thin steel coils. GMAW, commonly known as MIG welding, is an automated process that uses a continuous wire electrode and shielding gas. The electrode is fed through a welding gun, and an electric current creates an arc with the base material. This fast and efficient technique is suitable for high-volume production of steel coils. FCAW is a variation of GMAW that uses a tubular electrode filled with flux instead of a solid wire. The flux provides shielding gas and additional fluxing agents to protect the weld from impurities. FCAW is often preferred for welding thicker steel coils due to its better penetration and higher deposition rates. In addition to these techniques, laser welding and electron beam welding can be used for specific applications in steel coil manufacturing. These methods offer precise and high-quality welds but are typically more expensive and require specialized equipment. Ultimately, the choice of welding technique depends on factors such as material thickness, production volume, and specific product requirements.

- Q: How are steel coils used in the manufacturing of industrial pumps?

- Steel coils are used in the manufacturing of industrial pumps as a primary material for constructing the pump casing, impellers, and other critical components. The steel coils are first uncoiled and then cut into specific shapes and sizes, which are then formed, welded, and machined to create the various parts of the pump. The strength, durability, and corrosion resistance of steel make it an ideal choice for ensuring the longevity and reliability of industrial pumps in demanding applications.

- Q: Where are the coils and the steel plates used? Where did the steel plate come from?

- Steel coil is a kind of steel plate, also known as coil.The coil, like toilet paper, can roll into a barrel. (describe not very appropriate)When the coil is used, it is necessary to use the Kaiping machine to expand into a flat plate.

- Q: if someone wanted to melt cast steel or iron into small-relatively simple shapes such as rod-tapered rod-or etc... how would you go about melting the steel/iron what would the mold need to be made of?

- The other answers are correct. But don't attempt this unless you have lots of experience.

Send your message to us

Hot/Cold Rolled Steel Coil Chinese Supplier Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords