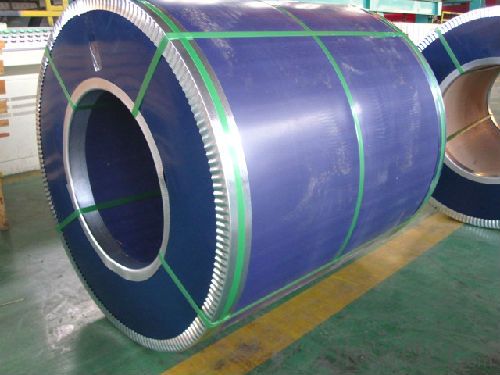

Hot Rolled Coil High Quality Cold Rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled Coil High Quality Cold Rolled at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Coil High Quality Cold Rolled are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Hot Rolled Coil High Quality Cold Rolled are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

One, introduction

Hot rolled coil is used for continuous casting slab or slab as raw material, after reheating furnace heating, scales entered the roughing mill in the high pressure water, roughing cut is expected by the head, tail, and then enter the finishing mill, the implementation of the computer controlled rolling, finally after rolling through the laminar cooling (computer controlled cooling rate) and coiling machine coiling, become straight hair volume. Hair straightener roll head, tail often forms a tongue shape and fishtail, thickness, width of poor accuracy, edge has wavy, folding, tower and other defects. The volume weight heavier, steel coil diameter is 760mm. (general pipe industry like use. )

2 two, characteristics

Because there is no after annealing treatment, the hardness is very high (HRB greater than 90), mechanical processing performance is poor, only a simplebending process has less than 90 degree directional (direction perpendicular to the rolled).

Three, use 3

Hot rolled products with high strength and good toughness, easy processing and good forming can be excellent performance of welding, which is widely used in ships, cars, bridges, buildings, machinery, boiler, pressure vesselmanufacturing industry.

The scope of application:

(1) after annealing processing into the common cold;

(2) processing galvanized galvanized unit before the annealing treatment;

(3) the basic do not need to process the panel.

4 four, classification

Carbon steel plate, carbon plate, low alloy plate, ship plate, bridge plate, boiler plate, container plate etc.. Rolling hard volumes: under normal temperature,the hot pickling volumes of continuous rolling.

Hot rolled steel strip products include steel (roll) and the shear of steel plate.And steel (coils) can be divided into straight and finishes volume (the volume,smooth rolling and slitting roll).

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: So I'm trying to decide which is better. I've always had aluminum on my 6 yr old tb gelding as I do hunters on him. He's never had steel on but I've recently moved and the shoer here is more expensive. So is aluminum really worth the extra cash to keep him light on his feet or is steel really not that much different?

- Shoes don't keep a horse light on their feet, good riding does. Aluminum bends really easily and will scratch and ruin quickly. That's why you have to have your horse shod more often with aluminum. Steel is worth it. They last longer. Personally though I think barefoot is the best option.

- Q: What are the challenges in coil leveling for coated steel?

- To achieve high-quality, flat, and smooth coils, several challenges must be addressed in the process of coil leveling for coated steel. The first challenge lies in the potential damage to the coating during leveling. Coated steel coils are typically covered with materials like zinc or paint, which are susceptible to scratching or marring if mishandled. The leveling process involves passing the coil through a series of rolls, which can cause friction, abrasion, or other mechanical harm to the coating. Therefore, it is crucial to meticulously control the speed, pressure, and alignment of the rolls to minimize coating damage. The second challenge stems from the variations in thickness across the coil. Coated steel coils often exhibit thickness discrepancies due to inherent material properties or production methods. These variations can lead to uneven leveling, resulting in coils with waviness or inconsistent flatness. Achieving uniform leveling across the entire coil surface is vital to ensure consistent quality and appearance of the final product. Another challenge in coil leveling for coated steel is the possibility of shape distortion. The coating processes can introduce stresses into the steel, causing the coil to warp or distort during leveling. This distortion can lead to coils with irregular edges or uneven flatness. Proper control of leveling process parameters, such as the number of passes and applied tension, is necessary to minimize shape distortion. Furthermore, the coil leveling process can generate internal stresses in the steel, especially in cold-rolled or heat-treated coated steels. These internal stresses can result in coil spring-back, where the coil attempts to revert to its original shape after leveling. Spring-back can cause coils with undesired curvature or inconsistent flatness. Effective strategies, such as stress relief annealing or employing counteracting leveling techniques, are essential to minimize spring-back and achieve the desired flatness. Lastly, handling and storing coated steel coils pose challenges in maintaining the quality of the leveled coils. Coated steel coils are sensitive to environmental conditions, such as humidity, temperature, and exposure to corrosive substances. Proper storage and handling practices are crucial to prevent coating damage, rust, or other forms of deterioration that can occur during transportation or storage. In conclusion, the challenges in coil leveling for coated steel involve minimizing coating damage, addressing thickness variation, controlling shape distortion and spring-back, and ensuring proper handling and storage. Overcoming these challenges necessitates precise control of process parameters, the application of suitable leveling techniques, and strict adherence to quality control measures throughout the entire process.

- Q: What are the common coil thickness and width combinations available for steel coils?

- The specific requirements and standards of the industry can cause the available combinations for steel coil thickness and width to vary. Nonetheless, there are commonly used combinations that can be found. There is a range of options for coil thickness, varying from thin to thick coils. Thin coils typically have a thickness of 0.4mm to 3.0mm, while medium thickness coils can be around 3.0mm to 6.0mm. Thicker coils can range from 6.0mm to 25.0mm or even higher, depending on the specific application. The coil width also varies depending on the intended usage. Common options include widths of 600mm, 750mm, 900mm, 1000mm, 1200mm, 1250mm, and 1500mm. However, wider or narrower coils can also be available depending on the specific requirements of the customer or industry. Ultimately, the most suitable combination of coil thickness and width will depend on factors such as the intended application, manufacturing processes, transportation limitations, and customer preferences. It is crucial to consult with steel coil manufacturers or suppliers to determine the most appropriate options for your specific needs.

- Q: i would like to know of any companies who buy shredded scrap steel

- We are one of the biggest steel mills in Asia. Under our group, we have steel mills in Thailand and Bangladesh. On the monthly basis, we purchase steel scrap HMS1/2 80:20 and the shredded ISRI210/211, ISRI211 by bulk and 20' container to Thailand and Bangladesh. Due to the limitation of our existing shredded steel scrap supplier, we need to get more supply of the shredded. Please contact us or offer us of ISRI 210/211 or ISRI211 CFR Chittagong, Bangladesh with 500mt - 2000mt per shipment by 20' container. If any questions, please feel free to contact us.

- Q: How are steel coils used in the production of industrial boilers?

- Steel coils are used in the production of industrial boilers to form the main body and components of the boiler, providing strength and durability. The coils are first shaped into the desired boiler structure, such as the shell and tubes, and then welded together to create a sturdy and leak-proof vessel. Additionally, the coils are often used to manufacture the heat exchangers and other critical parts of the boiler, ensuring efficient heat transfer and reliable operation.

- Q: How are steel coils inspected for chemical composition using spectroscopy?

- Spectroscopy techniques such as X-ray fluorescence (XRF) and laser-induced breakdown spectroscopy (LIBS) can be employed to examine the chemical makeup of steel coils. XRF involves directing an X-ray beam onto the surface of the steel coil, prompting the sample's atoms to emit distinct X-ray fluorescence radiation. By examining the energy and intensity of these emitted X-rays, one can determine the elemental composition of the steel. This method is both rapid and non-destructive, enabling swift and accurate assessment of the steel coil's chemical composition. On the other hand, LIBS entails focusing a laser beam onto the steel coil's surface, generating a high-temperature plasma. The plasma emits light, which is subsequently collected and analyzed using a spectrometer. This emitted light contains characteristic atomic and ionic emissions, allowing for the identification and quantification of various elements present in the steel. LIBS is also a non-destructive technique, providing real-time results and requiring minimal sample preparation. Both XRF and LIBS offer multiple benefits in terms of speed, non-destructiveness, and user-friendliness for inspecting the chemical composition of steel coils. These spectroscopic techniques play a vital role in quality control and assurance, ensuring that the steel meets the necessary specifications and standards for diverse industrial applications.

- Q: Went to top gun range in Houston, Tx. Guy there said no steel bullets..Anyone know why? Think i can shoot them anywhere else? Perhaps an outdoor gun range? The are monarch FMJ 9mm steel rounds..Thanks!

- However, I cannot under any circumstance travel with loaded rifle magazines in my car. Those I have to load at the range because it would be illegal for me to travel to the range with loaded magazines. Even if I don't have a rifle in the car, I cannot possess loaded rifle magazines while traveling. All long guns (shotguns included) must be unloaded and secured in the vehicle, including magazines or tubes. There are several states with restrictions against traveling with loaded rifle magazines, so I'd suggest you check your state laws first, and if it is permissible in your state, then find out if the range will allow it too.

- Q: I have a steel garage, it looks worn out hauled away? How can I maintain / repair it?

- The entire garage is steel? Garage door? Are you able to open and close it without too much trouble? If so, just keep it lubricated. You could paint the door to improve its appearance.

- Q: Theirs this two handed chinese sword on amazon with a forged combat steel blade and i was wandering if it means combat steel in the same sense that tempered carbon steel can be used?

- Combat steel? No such thing... Combat steel is a commercial product... not a true type of steel, since there is no ASTM grade of combat steel... And carbon steel is a WHOLE list of different types of steel, whether it's tempered or not... The company does not provide what steel specifications it has other than combat steel... So my best guess is that it's an alloy of 1095 or 301 spring tempered... both are resilient to snapping and fatigue, and common in modern swords... however, they do not hold an edge very well and are prone to rusting...

- Q: I'm looking to get a track bike/ fixie to ride around the city of Chicago. I've looked at many bikes and they're mostly made out of Hi Ten steel. My old fixie (which was stolen at North Ave Beach) was made out of aluminum (KHS FLITE 100). How big of a difference is it between aluminum and steel? I know steel is heavier but how does it effect the ride? Is a aluminum bike or a steel bike better to get to ride around the bike path and in the city of Chicago?

- Have you considered going to a motorcycle keep and watching at hybrid or commuter bikes? These will fall into cost range (ie. KHS, Fuji,and so on.). Aluminum is probably lighter than steel however the add-ons could make difference in the weight too. Go together with a motorbike shop that means you will be purchasing from folks who understand what they are selling. A series like performance Bike is a good way to go. The costs are right and which you can get a a lot bigger great bike in your money than you'll in finding at a department retailer, plus they provide lifetime free changes and tuneups.

Send your message to us

Hot Rolled Coil High Quality Cold Rolled

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords