Hot Rolled Channel Steel 2015 Hot Sell JIS Standard

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 30000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

2015 Hot Sell JIS Hot Rolled Channel Steel Details

Standard: | AISI,ASTM,BS,DIN,GB,JIS | Dimensions: | 50*37*4.5mm -400*104*14.5mm | Grade: | Q235 |

Place of Origin: | Hebei China (Mainland) | Brand Name: | jinding | Model Number: | 50*37*4.5mm -400*104*14.5mm |

Shape: | U Channel | Application: | construction | Perforated Or Not: | Is Perforated |

hot rolled: | channel steel | economic price: | channel steel | LC payment: | channel steel |

Packaging & Delivery

Packaging Detail: | Tied And Band With 6mm Wire Rod in Four Places Tightly |

Delivery Detail: | within 20 Days |

2015 Hot Sell JIS Hot Rolled Channel Steel Specifications

1.channel steel: ss400/q235/st37-2/a36/s235jr

2.channel steel 5.8/6/9/12m

3.LC payment channel steel

4.delivery within 25 day

Chinese standard size: 50*37*4.5mm -400*104*14.5mm

Japanese standard size: 50*25*3mm-300*90*13mm

| Size (mm) | Thickness (mm) | Thickness (mm) | Weight (kg/m) |

| 50*25 | 3.00~5.00 | 6.00 | 2.37~3.46 |

| 75*40 | 3.80 | 7.00 | 5.30 |

| 75*40 | 4.00 | 7.00 | 5.60 |

| 75*40 | 4.50 | 7.00 | 5.85 |

| 75*40 | 5.00 | 7.00 | 6.92 |

| 100*50 | 3.80 | 6.00 | 7.30 |

| 100*50 | 4.20 | 6.00 | 8.03 |

| 100*50 | 4.50 | 7.50 | 8.97 |

| 100*50 | 5.00 | 7.50 | 9.36 |

| 125*65 | 5.20 | 6.80 | 11.66 |

| 125*65 | 5.30 | 6.80 | 12.17 |

| 125*65 | 5.50 | 8.00 | 12.91 |

| 125*65 | 6.00 | 8.00 | 13.40 |

| 150*75 | 5.50 | 7.30 | 14.66 |

| 150*75 | 5.70 | 10.00 | 16.71 |

| 150*75 | 6.00 | 10.00 | 17.90 |

| 150*75 | 6.50 | 10.00 | 18.60 |

| 150*75 | 9.00 | 12.50 | 24.00 |

| 200*80 | 7.50 | 11.00 | 24.60 |

| 200*90 | 8.00 | 13.50 | 30.30 |

| 250*90 | 9.00 | 13.00 | 34.60 |

| 300*90 | 9.00 | 13.00 | 38.10 |

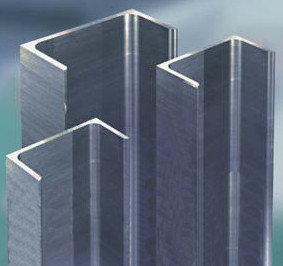

2015 Hot Sell JIS Hot Rolled Channel Steel Pictures

- Q: Can steel channels be used for supporting curtain wall systems?

- Certainly, curtain wall systems can indeed rely on steel channels for support. In construction, steel channels are widely utilized for providing structural support and can effectively furnish the requisite strength and stability necessary to bear the weight of curtain wall systems. Furthermore, steel channels can be conveniently tailored and manufactured to suit the specific design prerequisites of the curtain wall system. By affixing them to the building structure, they furnish a secure anchoring point for the curtain wall system, thereby ensuring its steadfastness and optimal functionality. In general, the robustness, longevity, and adaptability of steel channels make them a preferred choice for supporting curtain wall systems.

- Q: How do steel channels compare to other types of steel profiles?

- Steel channels have distinct advantages compared to other types of steel profiles. They are known for their high strength and durability, making them suitable for structural applications. Additionally, steel channels offer excellent load-bearing capabilities and can efficiently distribute weight, making them ideal for construction and engineering projects. Their unique shape provides versatility and ease of installation, ensuring stability in various applications. Overall, steel channels are a preferred choice due to their superior strength, versatility, and ability to withstand heavy loads.

- Q: What is the difference between channel steel and C steel?

- Section C is produced by cold rolling of strip steel, which is generally supplied by steel structure and thinner in thickness. In addition, their cross-section is not the same, the channel is straight side, C steel is curling.

- Q: How are steel channels connected to other structural members?

- Various methods are commonly used to connect steel channels to other structural members. One prevalent approach involves welding, where electric arc welding or other welding techniques are employed to weld the channels to other steel members. This welding process ensures a robust and permanent connection between the channels and the other members. Another method involves bolting. By using bolts, nuts, and washers, steel channels can be easily bolted to other members. This method allows for convenient disassembly and reassembly when necessary, making it suitable for specific applications. Rivets can also be used to connect steel channels in certain cases. This technique entails drilling holes through both the channels and the other members, and then inserting rivets into these holes. The rivets are then hammered or pressed to secure the connection. Although riveting provides a durable and reliable connection, it can be time-consuming and requires skilled labor. Moreover, mechanical connectors such as steel plates, brackets, or cleats can be utilized to connect steel channels to other members. These connectors are typically bolted or welded to both the channel and the other member, creating a strong and stable connection. Ultimately, the choice of connecting method for steel channels depends on project-specific requirements, the necessary load-bearing capacity, and the desired level of durability. Structural engineers and steel fabricators carefully consider these factors to determine the most suitable method for each application.

- Q: What are the standard lengths of steel channels?

- The standard lengths of steel channels vary depending on the manufacturer and supplier. However, common standard lengths for steel channels typically range from 20 feet to 40 feet.

- Q: Can steel channels be used for load-bearing walls?

- No, steel channels are typically not used as load-bearing walls in construction.

- Q: What are the different quality control measures for steel channels?

- There are several quality control measures for steel channels that ensure their strength, durability, and overall quality. Some of these measures include conducting visual inspections to check for any defects or imperfections, performing dimensional checks to ensure accurate measurements, conducting mechanical tests to assess the strength and load-bearing capacity, and implementing surface treatment processes to prevent corrosion and enhance the appearance. Additionally, steel channels may undergo non-destructive testing methods such as ultrasonic or magnetic particle inspections to detect any internal flaws. Overall, these quality control measures help guarantee that steel channels meet the desired specifications and industry standards.

- Q: What kind of low carbon steel or medium carbon steel are they?

- Low carbon steelLow carbon steel (low carbon steel) as the carbon content of less than 0.25% of the carbon steel, because of its low strength, low hardness and soft, it is also called the mild steel. It includes most of the ordinary carbon structural steel and some high-quality carbon structural steel, most of which are not used for engineering structural parts without heat treatment. Some of them are used for wear-resistant mechanical parts after carburizing and other heat treatment.The annealed structure of low carbon steel is ferrite and a small amount of pearlite, its strength and hardness are lower, and its plasticity and toughness are better. Therefore, its cold forming property is good, and cold forming can be carried out by curling, bending and stamping. This kind of steel also has good weldability. Carbon content from 0.10% to 0.30% low carbon steel is easy to accept all kinds of processing, such as forging, welding and cutting. It is used to make chains, rivets, bolts, shafts and so on.Low carbon steel is generally rolled into angle steel, channel steel, I-beam, steel pipe, steel belt or steel plate. It is used to make all kinds of building components, containers, boxes, furnaces and agricultural machinery and so on. High quality low carbon steel is rolled into thin board, making deep drawing products such as automobile cab, engine cover, etc., also rolled into bars, used for making mechanical parts of low strength requirement. Low carbon steel is not treated by heat before use. The carbon content is above 0.15%. It is treated by carburizing or cyaniding. It is used for shaft, shaft sleeve, chain wheel and other parts which require high surface temperature and good wear resistance.

- Q: How do steel channels contribute to the overall ease of maintenance for a structure?

- Steel channels contribute to the overall ease of maintenance for a structure in several ways. Firstly, steel channels provide structural support and reinforcement to the building, ensuring its stability and longevity. This reduces the need for frequent repairs and maintenance, as the structure can withstand external forces such as wind, earthquakes, and heavy loads without significant damage or deformation. Additionally, steel channels are highly durable and resistant to corrosion, rust, and decay. Unlike other materials such as wood or concrete, steel channels do not rot, warp, or deteriorate over time. This eliminates the need for regular inspections, repairs, or replacements due to structural degradation. Furthermore, steel channels can be easily fabricated and installed, allowing for efficient construction and maintenance processes. The versatility of steel channels enables engineers and architects to design and modify structures with ease, facilitating any necessary repairs or renovations. This results in reduced downtime and disruption during maintenance activities. Moreover, steel channels have a high strength-to-weight ratio, making them lightweight yet incredibly robust. This feature simplifies the transportation and handling of steel channels during maintenance projects. It also reduces the need for extensive structural modifications, as steel channels can often be added or replaced without compromising the overall integrity of the structure. Lastly, steel channels can be fire-resistant, providing an added layer of safety and ease of maintenance. In case of a fire incident, steel channels can help contain the spread of flames, minimize damage, and facilitate the restoration process. This reduces the complexity and cost of maintenance in the event of fire-related incidents. In summary, steel channels contribute to the overall ease of maintenance for a structure by providing structural support, durability, corrosion resistance, ease of fabrication and installation, lightweight design, and fire resistance. These characteristics result in reduced maintenance requirements, increased structural integrity, and improved cost-effectiveness over the lifespan of a building.

- Q: The role of channel?

- Channel steel is a kind of carbon structural steel used for construction and machinery. It is a complex section steel. Its cross section has a groove shape. Channel steel is mainly used in building structure, curtain wall engineering, mechanical equipment and vehicle manufacturing, etc.. In use, it requires better welding, riveting performance and comprehensive mechanical properties.

Send your message to us

Hot Rolled Channel Steel 2015 Hot Sell JIS Standard

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 30000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords