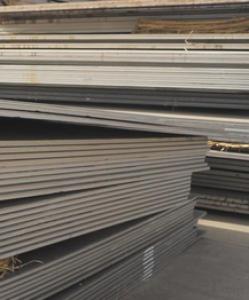

Hot Rolled Carbon Steel Plate,Carbon Steel Sheet ASTM A36 CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI, ASTM, GB, JIS | Grade: | Q195,Q235,Q345,A36,C45 | Thickness: | 1.0-30MM |

| Model Number: | Q235,Q195,Q345 | ||||

| Type: | Steel Plate | Technique: | Hot Rolled | Surface Treatment: | Coated |

| Application: | Ship Plate | Special Use: | Silicon Steel | Width: | 30-2000mm |

| Length: | as your requirement | standard: | hot rolled | Surface: | Anti-rust oil |

Packaging & Delivery

| Packaging Details: | seaworthy packages or as customers' require |

| Delivery Detail: | within 15 days after the advance payment |

Hot rolled steel plate

1 carbon steel plate 3mm thick General information

| Product name | Type | Specification | Implementation of GB | ||

| thick | wide | long | |||

| Carbon structural steel | Q195,Q215, Q235A,Q235B, Q235C,Q255, Q275 | 4-120 | 1500-4500 | 6000-12000 | GB/T700-2006 |

| Low-alloy structural steel | Q295,Q345A, Q345B,Q2345C | 4-120 | 1500-4500 | 6000-12000 | BG/T1591-1994 |

| Quality carbon structural stee | 30-50 | 4-120 | 1500-4500 | 6000-12000 | BG/T699-1999 |

| Ship steel | CCSA,CCSB | 4-120 | 1500-4500 | 6000-12000 | materials and welding condition |

| CCSAH32,CCSAH36 CCSDH32,CCSDH36 | 4-120 | 1500-4500 | 6000-12000 | materials and welding condition or GB 712-2000 | |

| Boiler steel | 20g,22Mng, 16Mng,19Mng | 4-120 | 1500-4500 | 6000-12000 | GB 713-1997 |

| Pressure vessel steel | 1622Mng,20R, 15MnVR,15MnVNR | 4-120 | 1500-2700 | 6000-12000 | GB 6654-1996 |

| European standard plate

| S235JR,S235J0, S275JR,S275J0, S275JR2,S355JR, S355J0,S355J2 | 4-120 | 1500-4500 | 6000-12000 | EN 10025 |

| Japanese standard plate | SS400,SS400-B | 4-120 | 1500-4500 | 6000-12000 | JIS G3101-2004 |

2 carbon steel plate 3mm thick detail specification

Material:

A283Gr.D/A573Gr.65,A516Gr65,A516Gr70,A284Gr.D

SS400,SS300,CCSB A36,A32,LRA32,LRB,Q235

Q195,Q235,Q345,SS400,ASTM A36,E235B

Thickness: 4mm-120mm

width: 1500mm-4500mm

Length:2-10m ,accordingly

Thickness | 4-120mm |

Width | 1500-4500mm or as custom's request |

Length | 2-12m,as your requirment |

Technique | Cold rolled or hot rolled |

Surface treatment | Bare, galvanized coated or as customer's requirements. |

Standard | ASTM,EN,GB,JIS,GB |

Material | A283Gr.D/A573Gr.65,A516Gr65,A516Gr70,A284Gr.D SS400,SS300,CCSB A36,A32,LRA32,LRB,Q235 Q195,Q235,Q345,SS400,ASTM A36,E235B |

Terms of Payment | L/C or T/T |

Chemical composition | C≤0.004%;Si≤0.030%; Mn ≤0.17%;P≤0.012%; S≤0.010%; Fe balance |

Delivery Detail | within 30days once receive deposite or confirm L/C |

Packing | Standard export packing,or as requirement |

3 carbon steel plate 3mm thick application:

construction,machinery manufacturing, container manufacturing, shipbuilding, bridge construction. Can also be used to manufacture a variety of containers, the furnace shell, furnace plate, bridge and vehicle static steel plate, low alloy steel plate,shipbuilding plate, boiler plate, pressure vessel plate, pattern plate, tractor parts, automobile frame steel plate and welding components

- Q: Can steel sheets be used in outdoor applications?

- Yes, steel sheets can be used in outdoor applications. Steel is a highly durable and strong material that can withstand various weather conditions, making it suitable for outdoor use. Steel sheets are commonly used in the construction industry for roofing, siding, and cladding applications. They are also used in outdoor storage sheds, fences, and gates. The corrosion resistance of steel can be improved through coatings such as galvanization or painting, which enhances its ability to withstand exposure to moisture and other environmental elements. Overall, steel sheets are a reliable choice for outdoor applications due to their strength, durability, and versatility.

- Q: What are steel sheets?

- Steel sheets are flat, thin metal plates made from steel that are commonly used in construction, manufacturing, and various other industries. They are versatile and durable, offering strength and resistance to corrosion, making them suitable for a wide range of applications.

- Q: What are the different methods of cutting steel sheets?

- There are several different methods of cutting steel sheets, including traditional methods such as shearing, sawing, and plasma cutting, as well as more modern techniques such as laser cutting and waterjet cutting. Each method has its own advantages and limitations, and the choice of method depends on factors such as the thickness and type of steel, desired precision, and production volume.

- Q: Can steel sheets be perforated or punched?

- Yes, steel sheets can be perforated or punched. Perforating or punching involves creating holes or designs in the steel sheet using specialized tools or machinery. This process is commonly used in various industries such as construction, automotive, and manufacturing to achieve specific functionality or aesthetics in the steel sheet.

- Q: How are steel sheets transported and stored?

- Steel sheets are typically transported and stored using specialized equipment such as forklifts, cranes, or flatbed trucks. They are often stacked in neat piles or bundled together to maximize space efficiency. To prevent damage, steel sheets are usually stored in covered warehouses or outdoor storage areas with proper protection against moisture and other environmental factors.

- Q: What is the process of manufacturing steel sheets?

- The process of manufacturing steel sheets involves several steps. First, iron ore is extracted from the ground and processed to remove impurities. This iron ore is then smelted in a blast furnace, along with coke and limestone, to produce molten iron. The molten iron is further refined in a basic oxygen furnace or an electric arc furnace to remove any remaining impurities and adjust the desired composition. Once the iron has been refined, it is converted into steel by adding alloying elements such as carbon, manganese, and other elements as required. The molten steel is then cast into large slabs or ingots. These slabs are reheated and passed through rolling mills to reduce their thickness and shape them into long, flat sheets. The sheets are then cooled, coated or treated as necessary, and cut into desired sizes before being packaged and shipped for various applications.

- Q: Are the steel sheets suitable for structural applications?

- Yes, steel sheets are highly suitable for structural applications. Steel is known for its exceptional strength and durability, making it an ideal choice for constructing buildings, bridges, and other structures that require stability and support. Steel sheets provide structural integrity due to their high tensile strength and ability to withstand heavy loads, making them capable of withstanding various environmental conditions, including earthquakes, hurricanes, and extreme temperatures. Additionally, steel sheets can be easily fabricated and shaped to meet specific design requirements, allowing for flexibility and versatility in structural applications.

- Q: Can the steel sheets be easily welded?

- Yes, steel sheets can be easily welded. Welding is a common method used to join steel sheets together. The process involves melting the edges of the steel sheets and then allowing them to cool and solidify, creating a strong bond. However, it is important to note that the ease of welding can depend on the type and thickness of the steel sheets, as well as the skill and experience of the welder. Additionally, proper safety precautions and welding techniques should be followed to ensure a successful and safe welding process.

- Q: How do steel sheets handle thermal expansion?

- Thermal expansion is managed by steel sheets through their ability to expand and contract in response to temperature fluctuations. When steel is heated, it expands, and when it is cooled, it contracts, just like any other material. However, steel has a relatively low coefficient of thermal expansion compared to other materials, meaning it expands and contracts less for a given change in temperature. This characteristic makes steel sheets more resistant to warping or buckling caused by thermal expansion. Moreover, steel is a robust and long-lasting material, enabling it to withstand the stresses resulting from thermal expansion without significant damage. To further address the effects of thermal expansion, engineers often incorporate expansion joints into structures or employ techniques such as pre-stressing and anchoring to accommodate the expansion and prevent harm. As a result of these properties and design considerations, steel sheets are able to effectively manage thermal expansion.

- Q: How do steel sheets compare to other types of sheet materials?

- Steel sheets are known for their exceptional strength, durability, and resistance to corrosion, making them superior to many other types of sheet materials. Additionally, steel sheets offer excellent thermal conductivity, making them suitable for various applications. However, steel sheets can be heavier and more expensive compared to some other materials, and their susceptibility to rust can be a disadvantage in certain environments.

Send your message to us

Hot Rolled Carbon Steel Plate,Carbon Steel Sheet ASTM A36 CNBM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 30 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords