Metcoppo Aluminum Roofing Sheets for Hot Rolled Aluminum Coils/Sheets for Tanker, Trailer Manufacturing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Pattern: orange peel, aluminum sheet5 bar,half a ball,diamond,compass shape

1.Orange peel aluminum sheet/coil

1)Alloy :1060 1100 1050 3003 3004 3105 5052

2)Temper :0 H114 H24 H32

3) Specification thickness:0.2mm-3.0mm

width:50mm-1300mm

Length: according your request

4)Application: Refrigeration. Air-conditioner. keep warm well such as pipe ,tank

5)Surface: No crack,canker, hole

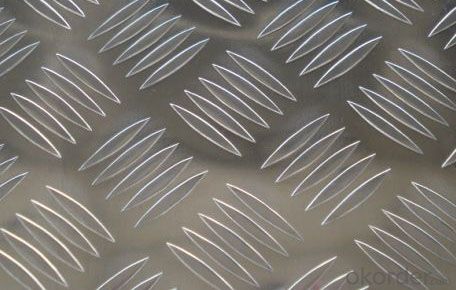

2. aluminum sheet5 bar/coil

1)Alloy :1060 1100 1050 3003 3004 3105 5052 5754 5083 6061 6063 6082

2)Temper: O H114H194 T6

3) Specification: Thickness:1.0mm-10mm

Width:50mm-2000mm

Length: according your request

4)Application: the main function is anti-skidding,widely used in automobile manufacturing,shipbuilding,machine manufacturing,elerator,workshop

5)Surface: No crack,canker, hole

3.Compass shape aluminum sheet/coil

1)Alloy:1060 1100 1050 3003 3004 3105 5052 5754 5083 6061 6063 6082

2)Temper: O H114 H194 T6

3) Specification: thickness:1.0mm-10mm

width:50mm-2000mm

Length: according your request

4)Application: the main function is anti-skidding,widely used in automobile manufacturing,shipbuilding,machine manufacturing,elerator,workshop

5)Surface: No crack,canker, hole

4.Diamond aluminum sheet/coil

1)Alloy:1060 1100 1050 3003 3004 3105 5052 5754 5083 6061 6063 6082

2)Temper: O H114 H194 T6

3) Specification: Thickness:1.0mm-10mm

Width:50mm-2000mm

Length: according your request

4)Application: building industry,packing,decorative

5)Surface: No crack,canker, hole

4) Delivery time: 15-20 days after confirming order.

For all above:

1) Minimum order quantity: 5 tons per size.

2) The term of payment: T/T, irrevocable L/C at sight.

3) Packing: Export standard, waterproof wooden,craft,plywood pallet,etc.

- Q: This question asks for methods to preserve the aesthetic quality of aluminum sheets and prevent deterioration over time.

- <p>To maintain the appearance of aluminum sheets over time, follow these steps: 1. Regularly clean the sheets with a mild detergent and water to remove dirt and grime. 2. Avoid using harsh chemicals or abrasive materials that can scratch the surface. 3. Apply a protective coating or sealant if the sheets are exposed to harsh weather conditions or corrosive environments. 4. Inspect the sheets periodically for signs of corrosion or damage and address any issues promptly. 5. Keep the aluminum sheets dry, as moisture can lead to rust and other forms of deterioration. Proper maintenance will help preserve the appearance and longevity of aluminum sheets.</p>

- Q: Are aluminum sheets prone to warping?

- Yes, aluminum sheets are prone to warping, especially when exposed to high temperatures or subjected to excessive pressure. However, the extent of warping depends on various factors such as the thickness of the sheet, the specific alloy used, and the conditions it is exposed to.

- Q: What is the surface finish of 101 aluminum sheets?

- The surface finish of 101 aluminum sheets can vary depending on the specific manufacturing process and desired application. However, common surface finishes for 101 aluminum sheets include mill finish, brushed finish, anodized finish, and painted finish. Mill finish refers to the raw, untreated surface of the aluminum sheet, which may have some minor imperfections or scratches. Brushed finish is achieved by brushing the surface of the sheet with a fine abrasive material, resulting in a smooth, satin-like appearance. Anodized finish involves an electrochemical process that forms a protective oxide layer on the surface of the aluminum, providing enhanced durability and corrosion resistance. Painted finish, on the other hand, involves applying a layer of paint onto the aluminum sheet to provide color and additional protection. Ultimately, the choice of surface finish for 101 aluminum sheets depends on the desired aesthetic, functional, and environmental requirements of the application.

- Q: What are the disadvantages of using aluminum sheets?

- One major disadvantage of using aluminum sheets is their relatively low strength compared to other materials like steel. This can limit their application in certain industries or environments where high structural integrity is required. Additionally, aluminum sheets are prone to corrosion, especially when exposed to certain chemicals or salty environments, which can reduce their lifespan and durability. Lastly, aluminum sheets can be more expensive than other materials, making them less cost-effective for certain projects or budgets.

- Q: Can aluminum sheet be used for architectural applications?

- Yes, aluminum sheet can be used for architectural applications. Aluminum is a versatile material known for its strength, durability, and corrosion resistance. It is commonly used in the construction industry for architectural cladding, roofing, and facades, among other applications. Aluminum sheets are available in various thicknesses, allowing architects and designers to achieve different aesthetic and functional requirements. They can be easily shaped, bent, and formed to create unique architectural elements, such as panels, screens, louvers, and decorative features. Furthermore, aluminum sheets can be coated or finished to enhance their appearance and protect them from environmental factors. Anodizing, powder coating, or painting can be applied to improve the material's resistance to weathering, UV radiation, and pollution. The lightweight nature of aluminum makes it a preferred choice for architectural applications as it reduces the overall weight of the structure and facilitates easier installation. Additionally, aluminum is a sustainable material that can be recycled indefinitely, making it an environmentally friendly option for architectural projects. In conclusion, aluminum sheets are a viable and popular choice for architectural applications due to their strength, versatility, durability, and aesthetic appeal.

- Q: What is the tensile strength of 101 aluminum sheets?

- The tensile strength of 101 aluminum sheets varies depending on the thickness and manufacturing process, but it typically ranges from 20,000 to 30,000 pounds per square inch (PSI).

- Q: What are the potential safety issues associated with the use of aluminum sheets?

- <p>Aluminum sheets are generally safe to use, but there are a few considerations. They can be sharp when cut, so proper handling is important to avoid cuts. Aluminum is a good conductor of heat, so care should be taken to avoid burns when handling hot aluminum sheets. Additionally, inhalation of aluminum dust can be harmful, so it's important to work in a well-ventilated area or use a dust mask when cutting or grinding aluminum. In terms of long-term health, there's ongoing debate about the safety of aluminum exposure, but it's generally considered safe when used in accordance with proper safety measures.</p>

- Q: What is the thickness range available for aluminum sheets?

- The specific requirements and applications can cause the thickness range of aluminum sheets to vary. Typically, aluminum sheets come in a variety of thicknesses, ranging from very thin at 0.006 inches (0.15mm) to very thick at 0.5 inches (12.7mm) or even thicker in certain cases. It should be noted that the supplier or manufacturer may have different availability of specific thicknesses. Furthermore, specialized fabrication processes can often provide custom thicknesses.

- Q: What are the different types of aluminum sheets available?

- There are several different types of aluminum sheets available, each with their own unique properties and uses. Some of the most common types include: 1. Pure Aluminum Sheets: These sheets are made from 100% aluminum and are known for their excellent corrosion resistance and high thermal conductivity. They are often used in applications where lightweight and durability are important, such as in the aerospace industry. 2. Aluminum Alloy Sheets: These sheets are made by combining aluminum with other elements, such as magnesium, copper, or zinc, to enhance specific properties. For example, aluminum-magnesium alloy sheets (5000 series) are known for their excellent strength and resistance to corrosion, making them suitable for marine applications. 3. Painted Aluminum Sheets: These sheets have a layer of paint or coating applied to their surface, providing them with additional protection against corrosion and enhancing their aesthetic appeal. They are commonly used in architectural projects and signage. 4. Perforated Aluminum Sheets: These sheets have small holes or perforations evenly spaced across their surface. They are often used in applications where airflow or visibility is required, such as in HVAC systems, decorative panels, or speaker grilles. 5. Embossed Aluminum Sheets: These sheets have a raised pattern or design on their surface, achieved through a process of embossing. This not only adds visual interest but also increases the strength of the sheet, making it suitable for applications such as flooring, vehicle panels, or decorative purposes. 6. Anodized Aluminum Sheets: This type of aluminum sheet undergoes an electrolytic process called anodizing, which forms a protective layer on its surface. Anodized sheets are highly resistant to corrosion and wear, making them ideal for outdoor applications, such as building facades, window frames, or automotive trim. It is important to consider the specific requirements of your project before selecting the type of aluminum sheet. Factors such as strength, corrosion resistance, appearance, and cost should be taken into account to ensure the right sheet is chosen for the job.

- Q: Can aluminum sheets be used for elevator interiors?

- Indeed, elevator interiors can certainly be constructed using aluminum sheets. Aluminum has gained significant popularity as a material of choice for elevator interiors due to its multitude of advantageous qualities. Its lightweight nature, durability, and resistance to corrosion render it highly suitable for long-term utilization in elevator applications. With ease, aluminum sheets can be skillfully fabricated and shaped to perfectly fit the dimensions and design specifications of elevator interiors. Furthermore, aluminum can be enhanced with various types of coatings or finishes, such as anodizing or powder coating, to not only augment its aesthetic appeal but also provide additional protection. Overall, aluminum sheets represent a practical and widely utilized option for elevator interiors within the industry.

Send your message to us

Metcoppo Aluminum Roofing Sheets for Hot Rolled Aluminum Coils/Sheets for Tanker, Trailer Manufacturing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords