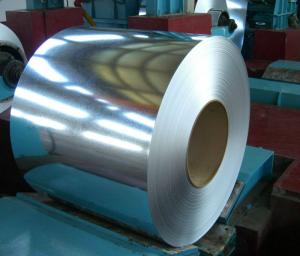

Hot Rolls Steel Coils Cheap Price Made In China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

DESCRIPTION FOR CARBON STEEL PLATE

Production | hot rolled steel coils ss400 |

Port | Tianjin, China |

Category | Minerals & metallurgy |

Thickness | 1.8-16mm |

Width | 1000-1500mm |

Coil Weight | about 23 tons |

Material Grade | SS400\Q235\Q345B |

Technique | Hot Rolled |

Standard | GB ,JIS |

Test | With Hydraulic Testing, Eddy Current , Infrared Test |

Surface | 1) Bared 2) Black Painted (varnish coating) 3) Galvanized 4) Oiled |

Package | in bundles, strapped by strips. Or as customer’s requirement |

Sample | Common products, we can provide freely, for special production,we can depends on negotiation. |

MOQ | 50 tons |

Payment | 100% L/C at sight, 30% T/T in advance, and the balance against the copy of B/L or negotiation |

Delivery time | Within 10-25 days, according to quantity, asap save customer’s time |

Certificate | ISO |

PACKING:

1.Big thickness:by bulk vessel

2.Small thickness:packed by steel strips and shipped by container

3.According to the requirements of customers'

TRADE TERMS :FOB, CFR, CIF

DETAILED PICTURES FOR STEEL COILS

EXPORT MARKET FOR STEEL COILS/SHEETS

Our target market is the international market. Every year we export most of products to countries like India, Pakistan, South Korea, Brazil, Australia, South Africa, Spain, Sri Lanka, Taiwan, Hong Kong, etc.

FAQ:

Q:How about the trade terms?

A:EXW,FOB,CFR,CIF will be accepted.

Q:How about your payment terms?

A:30%TT in advance and the balance against of copy of B/L.The irrevocable L/C at sight will be accepted.

- Q: Suppose you made a sword out of diamond (just follow me here, it's only theoretical). Would it be lighter than a sword of the same size made out of steel?

- The weight of steel is dependent among what kind of steel, shape, length, width, thickness a 5mm by 5mm ball of carbon steel would wiegh 1.69969 g a same size diamond weighs .79 carats equivelent to 1.5 grams So the basic answer is, yes, diamond is lighter than steel, but barely

- Q: How are steel coils used in the manufacturing of agricultural silos?

- Steel coils are used in the manufacturing of agricultural silos to create the cylindrical structure of the silo. These coils are rolled and shaped into large, seamless rings that form the walls of the silo. The coils provide strength and durability to withstand the weight of the stored grain or other agricultural products, ensuring the structural integrity of the silo.

- Q: How are steel coils used in the production of storage racks?

- Steel coils are used in the production of storage racks by being uncoiled, cut, and shaped into the required dimensions and components of the racks. These steel coils provide the necessary strength and durability to support heavy loads and ensure the stability and longevity of the storage racks.

- Q: How are steel coils used in the manufacturing of aerospace components?

- Steel coils are used in the manufacturing of aerospace components primarily for their strength, durability, and ability to withstand high temperatures. These coils are typically formed into various shapes and sizes to create structural parts like fuselage frames, landing gear components, and engine mounts. The steel coils provide the necessary strength and rigidity to ensure the structural integrity of these aircraft components, making them essential in the aerospace industry.

- Q: What are the common size limitations for steel coils?

- The common size limitations for steel coils vary depending on the specific requirements of the industry or application. However, there are some general size limitations that are commonly followed in the steel manufacturing and distribution industry. The width of steel coils typically ranges from as narrow as 0.25 inches (6.35 mm) to as wide as 72 inches (1828.8 mm). This wide range allows for versatility in various applications, from automotive parts to construction materials. The thickness of steel coils can also vary significantly, usually ranging from 0.006 inches (0.15 mm) to 0.5 inches (12.7 mm). Thinner coils are often used in applications that require lighter weight and flexibility, while thicker coils are commonly utilized in heavy-duty applications that demand strength and durability. The weight of steel coils is another factor to consider, especially for transportation and handling purposes. Typically, steel coils can weigh anywhere from a few hundred pounds to several tons. The weight limitations are dependent on factors such as the size of the coil, the steel grade, and the equipment used for transportation and storage. Furthermore, the outer diameter of steel coils can also have limitations. It usually ranges from 24 inches (609.6 mm) to 72 inches (1828.8 mm). The inner diameter, on the other hand, can vary from 16 inches (406.4 mm) to 24 inches (609.6 mm). These dimensions are critical for ensuring compatibility with processing equipment and storage racks. It is important to note that these size limitations are not fixed and can be customized based on specific requirements. Steel manufacturers and distributors often work closely with their customers to determine the optimal size and dimensions of the coils to meet their specific needs and ensure efficient handling and processing.

- Q: How are steel coils used in the manufacturing of railroads?

- Steel coils are used in the manufacturing of railroads as they are the primary material for constructing railway tracks. These coils are processed to form rails, which are then laid down to create the tracks on which trains run. The durable and strong nature of steel coils ensures the tracks can withstand the high loads and stresses imposed by trains, ensuring safe and efficient transportation.

- Q: I just want regular steel, not stainless steel.

- Iron is the primary ingredient in steel. All Steel is an alloy by definition. Stainless steels are alloys that resist corrosion. There are dozens of alloys of steel. Many stainless steels are not magnetic. If a magnet won't stick to it it is very likely to be a stainless steel but that is not true for all stainless steels. You really do need to be more specific as to what you want and why. There are too many to chose from.

- Q: Why is the steel tape tape head not fixed?

- There are better tape measures, heads and magnets. For measuring steel objects, one can operate long distances.

- Q: What are the key properties of steel coils?

- The key properties of steel coils include their strength, durability, and flexibility. Steel coils are known for their high tensile strength, making them suitable for various applications that require load-bearing capacity. They also exhibit excellent durability, resisting wear, corrosion, and damage over time. Additionally, steel coils are highly flexible, allowing for easy shaping and forming into different structures or products.

- Q: I know copper pots are supposed to be really good for cooking with, and I have been looking around online. One thing I don't want to do, however, is send them in to be re-lined with tin. So I was wondering if stainless steel lined copper pots work as well as the traditional tin lined ones, or if those make the copper just for looks.

- Stainless steel is durable and does not disolve and make things taste funny. Stainless steel is not a good conductor of heat, so it has hot and cold spots. Copper is very good conductor. They noe bond copper to stainless steel to get the best features of each. Some pots just have a very thin copper plating to fool you. A good pot will be heavier, It is really hard to tell from looking.if it is plating or a bonded layer of copper. the thicker the better

Send your message to us

Hot Rolls Steel Coils Cheap Price Made In China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords