Hot-Dip Galvanized Steel Roof with Different Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Hot-Dip Galvanized Steel Roof Description:

Hot-dip galvanized steel roof are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial application.

2.Main Features of the Hot-Dip Galvanized Steel Roof:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

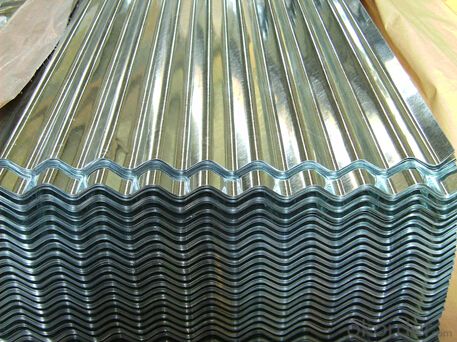

3.Hot-Dip Galvanized Steel Roof Images

4.Hot-Dip Galvanized Steel Roof Specification

Material: Galvanized Sheet

Width: 650/800/890/900

Length: 1500/1800/2000/2400/3005/3600 or customized

Thickness: 0.2-2.0

Surface Treatment: Hot dipped/Bended

Application: warehouse; shelter; Commercial facilities; industrial facilities

5.FAQ of Hot-Dip Galvanized Steel Roof

Which payment term we can do?

L/C at sight or T/T.

What’s the basic material of this product?

Galvanized/Aluzinc Steel

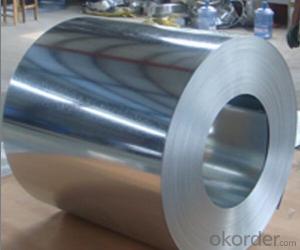

What’s the coating composition of Hot-Dip Galvanized Steel Coil?

The coating composition is 55% aluminium in weight ratio, 43.4% zinc, and 1.5% silicon, with excellent corrosion and heat resistance performance.

- Q: What are the different types of coil edge trimming machines?

- There are several types of coil edge trimming machines available in the market. Some common types include manual coil edge trimmers, pneumatic coil edge trimmers, and automatic coil edge trimmers. Manual coil edge trimmers require manual operation and are suitable for low volume production. Pneumatic coil edge trimmers use compressed air to power the trimming process, making them faster and more efficient. Automatic coil edge trimmers are fully automated machines that can handle high volume production, enhancing productivity and reducing labor requirements.

- Q: How do steel coils contribute to the manufacturing of appliances?

- Appliances heavily rely on steel coils in their manufacturing process. Typically crafted from high-quality steel, these coils serve various purposes throughout appliance production. To begin with, appliance manufacturers employ steel coils to fabricate essential components. These coils are instrumental in constructing the outer and inner casings of appliances such as refrigerators, washing machines, and dishwashers. The resilient properties of steel ensure durability and safeguard the internal mechanisms of the appliance. Furthermore, steel coils find application in the production of appliance parts. They are often cut, shaped, and transformed into smaller elements such as brackets, frames, and panels. These parts play a crucial role in enabling appliances to function properly and contribute to their overall performance and lifespan. In addition, steel coils significantly contribute to the manufacturing of appliance doors. Molding and shaping the coils allows the creation of sturdy doors, which are vital for the accessibility and safety of the appliance. Steel doors offer strength, security, and insulation, making them an ideal choice for appliances. Moreover, steel coils are utilized in the manufacturing of heating elements and burners for appliances like stoves and ovens. These coils are designed to withstand high temperatures and efficiently transfer heat, ensuring that the appliances can effectively cook or bake food. Overall, steel coils play an integral role in the appliance manufacturing process. They are employed to construct the outer casings, vital components, doors, and heating elements of appliances. The utilization of steel in these applications enhances durability, safety, and overall performance, resulting in more reliable and long-lasting appliances.

- Q: How can the outer diameter and weight of steel coil be converted?

- To obtain the outer diameter of the steel coil is calculated according to the density of 7850, according to the density, in general, hot-rolled is 0. 96~0, 98, cold rolled, according to 0. 98~0. Ninety-nine

- Q: How are steel coils used in the petrochemical industry?

- Steel coils are commonly used in the petrochemical industry for various purposes such as manufacturing pipes, tanks, and equipment used in the processing and transportation of petrochemical products. The coils are typically formed into specific shapes and sizes to meet the industry's requirements, ensuring structural integrity and resistance to corrosion. These steel components play a critical role in maintaining the safety and efficiency of petrochemical operations.

- Q: I am a complete idiot when it comes to anything musical, so please forgive me if this is a stupid question. I bought my son his first guitar, acoustic and didnt realize until after I purchased it that it has steel strings. Can I have the strings changed from steel to nylon???

- Nylon strings are more commonly used for classical style acoustic guitars, and most standard acoustics are set up to use steel strings. Nylon strings have less tension than steel strings so the sound won't be as full as steel strings. You may also notice some loud vibration from the top of the guitar since the strings don't have the proper tension. A guitar made for nylon strings uses thinner wood and is braced differently than one made for steel strings. The nylon strings won't put enough energy into the steel string guitar to make it vibrate correctly and develop the volume and harmonics that steel strings would. EDIT: To answer the second part of your question, it doesn't really matter what type of strings a beginner learns on. Nylon strings will be a little softer on the fingers, but once you build up calluses on your fingers it doesn't hurt anymore. There is no distinct advantage to a beginner learning with nylon strings as opposed to steel strings.

- Q: which elements are alloyed to make stainless steel?A Fe, CB Fe, MnC Fe, NiD Fe, CrE Fe, Cr, Ni

- E. Stainless steel is mainly comprised of Cr and Ni. Steel is an alloy composed mainly of iron. On a side note, Carbon is not really in stainless steel and it is only less than .1%

- Q: What is the role of steel coils in the production of conveyors?

- Steel coils are used in the production of conveyors as they serve as the main structural component for supporting and guiding the conveyor belt. These coils are typically formed into a cylindrical shape and act as a sturdy foundation for the belt to rest on. Additionally, the strength and durability of steel coils ensure that the conveyor can withstand heavy loads and constant movement, making them essential for efficient and reliable conveyor systems.

- Q: I am building a steel type competative team. my team so far isempolem, skarmory , Metagross, magnezone, lucario, ferrothorn.

- I'd say add Excadrill to the team. He's got pretty decent stats and a nice learnset. Otherwise Probopass works pretty well

- Q: I need details for steel column splices welded or bolted. References or autocad blocks will be very useful. Thank you very much!

- Boy oh boy, that request would open you up to a bunch of different types of files and drawings. There are so many different ways to make a column splice for structural steels. And they all would depend greatly on the loads that the joint will be subject too. You need to find a copy of the Manual of Steel Construction Ninth edition (or newer if its out, mine is the ninth), from the AISC 'American Institute of Steel Construction. This book will show you quite a few different connection options, welded and bolted. You will need to make drawings from the dimensions and details you see in the book. One other thing, you might try to find a manual for steel detailing, the seventh edition of the above book had a section to show detailing dimensions for different steel elements, dependant on the size and shape of the member itself.

- Q: What are the different types of steel coil slitting knives?

- There are several different types of steel coil slitting knives, including circular slitting knives, straight slitting knives, and crush-cut slitting knives. These knives are used for precision cutting and slitting of steel coils into narrower strips or sheets. Circular slitting knives feature a circular shape with sharp edges, while straight slitting knives have a straight cutting edge. Crush-cut slitting knives have a unique design that allows them to crush and cut the material simultaneously. Each type of knife is used for specific applications and offers different advantages depending on the desired outcome.

Send your message to us

Hot-Dip Galvanized Steel Roof with Different Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords