Hot-Dip Galvanized Steel Roof with Best Quality of China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Hot-Dip Galvanized Steel Roof Description:

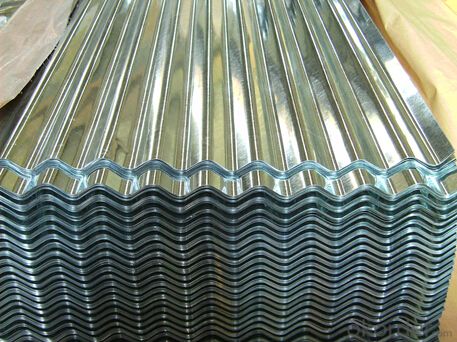

Hot-dip galvanized steel roof are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial application.

2.Main Features of the Hot-Dip Galvanized Steel Roof:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Roof Images

4.Hot-Dip Galvanized Steel Roof Specification

Material: Galvanized Sheet

Width: 650/800/890/900

Length: 1500/1800/2000/2400/3005/3600 or customized

Thickness: 0.2-2.0

Surface Treatment: Hot dipped/Bended

Application: warehouse; shelter; Commercial facilities; industrial facilities

5.FAQ of Hot-Dip Galvanized Steel Roof

Which payment term we can do?

L/C at sight or T/T.

What’s the basic material of this product?

Galvanized/Aluzinc Steel

- Q: How are steel coils used in the manufacturing of railroads?

- Steel coils are used in the manufacturing of railroads as they serve as a primary raw material for producing railway tracks. These coils are processed and cut into appropriate lengths, then shaped into rails through a series of rolling and forging techniques. The resulting rails provide the necessary strength, durability, and stability required to support heavy loads and withstand the wear and tear of train traffic.

- Q: What are the main factors that affect the flatness of steel coils?

- The main factors that affect the flatness of steel coils include the quality and consistency of the incoming raw material, the precision of the rolling process, the tension applied during rolling, the cooling and annealing processes, and the handling and storage of the finished coils.

- Q: What are the main challenges in handling and processing steel coils?

- The main challenges in handling and processing steel coils include their large size and weight, which require specialized equipment and techniques for safe transportation and storage. Coils also tend to have sharp edges, posing a risk of injury. Additionally, maintaining the integrity and quality of the steel during processing can be challenging due to the potential for surface damage, rust, or deformation. Proper handling, storage, and processing techniques are crucial for minimizing these challenges and ensuring the efficient production of steel products.

- Q: I want to buy a VERY sturdy bunkbed, but don't know which one would be better with not getting loose or falling apart.

- Metal/Steel, tighten it down and put some washers in between the steel and the screw so it creates a tight fit and movement wont affect the screw directly.

- Q: How is it used easy 10 points just tell me how its used or any intersting facts this is for my comp science paper lol. I know what the hell does steel have to too do with computers he is a Fg! Please be descriptive THANKS! FAST ANSWERS TOO it 9pm bedtime for a 14 year old lol..

- steel is used for cars and trains. one of the largest steel manufacturers is in my town its called CarTech its in reading pa.

- Q: What are the common coil widths available for steel coils?

- The common coil widths available for steel coils vary depending on the specific application and industry requirements. However, there are several standard coil widths that are commonly available in the steel industry. These include: 1. 24 inches (approximately 610 mm): This is a common coil width used for various applications, including automotive manufacturing, construction, and general engineering. 2. 36 inches (approximately 914 mm): This wider coil width is often used in the construction industry for roofing and siding materials. 3. 48 inches (approximately 1219 mm): This wider coil width is commonly used in manufacturing processes where larger steel sheets are required, such as in the production of appliances, HVAC systems, or industrial machinery. 4. 60 inches (approximately 1524 mm): This wider coil width is typically used for specialized applications in industries such as automotive manufacturing, aerospace, or shipbuilding. It is important to note that while these are some of the more common coil widths, steel coils can be produced in custom widths to meet specific customer requirements. Additionally, the availability of coil widths may vary depending on the steel mill or supplier.

- Q: How are steel coils shaped into specific forms?

- Steel coils are shaped into specific forms through a process called cold rolling, where the coils are passed through a series of rollers that apply pressure to gradually shape and form the steel into the desired shape.

- Q: What are the different surface finishes of steel coils?

- The different surface finishes of steel coils include mill finish, galvanized finish, painted finish, and coated finish.

- Q: Can steel coils be stretched?

- Yes, steel coils can be stretched.

- Q: What are the dimensions of steel coils used in the packaging industry?

- The dimensions of steel coils used in the packaging industry can vary depending on the specific application and requirements. However, typical dimensions for steel coils used in packaging range from 0.15 mm to 3 mm in thickness and 600 mm to 2000 mm in width. The inner diameter of the coil, known as the core, is usually around 508 mm (20 inches), although other sizes such as 610 mm (24 inches) or 762 mm (30 inches) may also be used. The outer diameter of the coil can vary depending on the weight and size of the coil, but it is commonly around 1000 mm to 2000 mm. It is important to note that these dimensions can be customized based on the specific requirements and preferences of the packaging industry.

Send your message to us

Hot-Dip Galvanized Steel Roof with Best Quality of China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords