Hot Dip Galvanized Steel Plate in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Galvanized Steel Coil Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications.

2.Main Features of the Galvanized Steel Coil:

• Base material for countless outdoor and industrial applications

• High corrosion resistance

• High strength

• Good formability

• Rust- proof ability

• Good visual effect

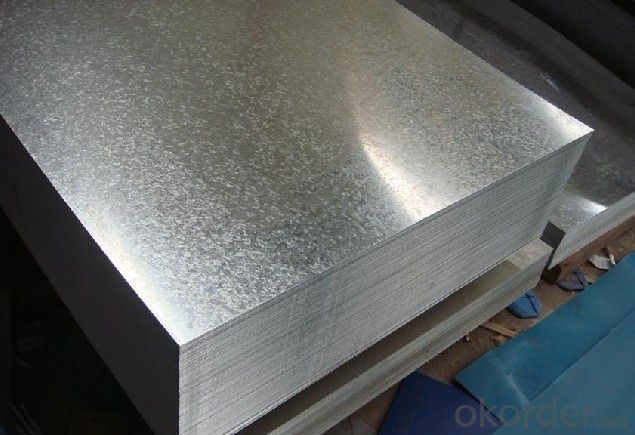

3.Galvanized Steel Coil Images

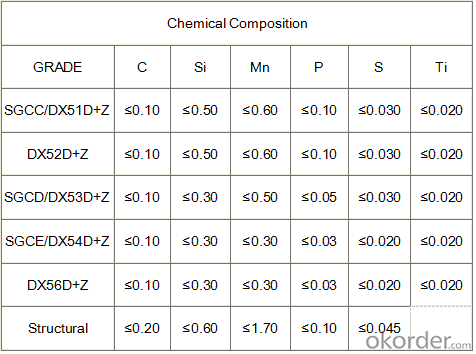

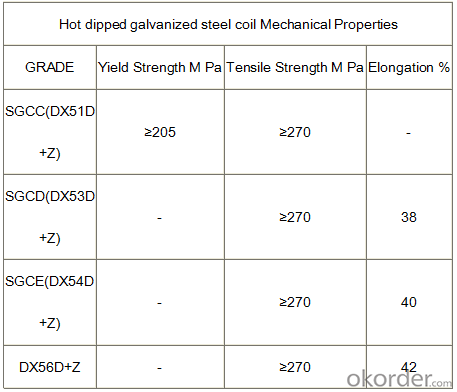

4.Galvanized Steel Coil Specification

Operate Standard: ASTM A653M-04/JIS G3302/DIN EN10143/GBT 2518-2008

Grade : SGCD,SGCH, Q195,DX51D

Zinc coating :40-180g( as required)

Width:914-1250mm(914mm, 1215mm,1250mm,1000mm the most common)

Coil id:508mm/610mm

Coil weight: 4-10 MT(as required)

Surface: regular/mini/zero spangle, chromated, skin pass, dry etc.

5.FAQ of Galvanized Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

3.How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: Can steel coils be welded together?

- Yes, steel coils can be welded together. Welding is a common technique used to join metals, including steel coils. It involves melting the edges of the coils and fusing them together using a filler material. This process creates a strong and durable bond between the coils, allowing them to be joined and used as a single unit. Welding steel coils together is commonly done in various industries, such as manufacturing, construction, and automotive, to create larger structures or components. However, it is important to ensure proper welding techniques and quality control measures are followed to ensure the integrity and strength of the weld joint.

- Q: hello friends, I have some old 7.62x54r on stripper clips its nasty gunk on it can i use steel wool to glean it and still have it fire safely?

- * Yes, but I use both fine steel wool and Liquid Brasso Metal Polish on mine.* You can buy it at any Hardware and I believe Walmart carries it.* Great stuff.*

- Q: How are steel coils used in the oil and gas industry?

- Steel coils are used in the oil and gas industry for various purposes such as pipelines, storage tanks, and drilling equipment. These coils are commonly used to manufacture seamless and welded pipes that are essential for transporting oil and gas from production sites to refineries and end-users. Additionally, steel coils are utilized in the construction of storage tanks that store oil and gas in large quantities. They are also an integral part of drilling equipment, including offshore platforms, where they provide structural support and withstand high-pressure environments.

- Q: How are steel coils processed and treated?

- Steel coils are processed and treated through a series of steps. Initially, the steel is cleaned and pickled to remove any impurities. It is then passed through a series of rolling mills to reduce its thickness and increase its length. The coils are then annealed to improve their strength and ductility. Further treatments such as galvanizing or coating can be applied to enhance corrosion resistance or improve aesthetic appeal. Finally, the coils are cut and packaged according to customer specifications before being shipped for various applications in industries such as construction, automotive, and manufacturing.

- Q: What are the dimensions of steel coils used in the construction materials industry?

- The dimensions of steel coils used in the construction materials industry can vary depending on the specific application and requirements. However, common dimensions for steel coils in this industry range from 0.5mm to 3mm in thickness and 600mm to 2000mm in width. The length of steel coils can vary, but it is typically between 1000mm to 6000mm.

- Q: How are steel coils transported?

- Steel coils are typically transported by truck, train, or ship, depending on the distance and location. They are usually secured with steel strapping or wire rope and loaded onto specialized trailers or containers designed to handle their weight and size.

- Q: What are the key players in the steel coil manufacturing industry?

- The key players in the steel coil manufacturing industry are typically large multinational companies that have significant market share and influence. Some of the prominent players in the industry include: 1. ArcelorMittal: As the world's largest steel producer, ArcelorMittal is a major player in the steel coil manufacturing industry. They operate in more than 60 countries and have a diversified product portfolio. 2. Nippon Steel Corporation: Nippon Steel is a leading Japanese steelmaker and one of the largest steel coil manufacturers globally. They have a strong presence in automotive and construction sectors. 3. POSCO: Based in South Korea, POSCO is a major player in the steel industry, including steel coil manufacturing. They are known for their high-quality products and advanced technology. 4. Baosteel Group Corporation: Baosteel is the largest steelmaker in China and one of the largest globally. They have a wide range of steel products, including steel coils, and are known for their strong research and development capabilities. 5. Thyssenkrupp AG: Thyssenkrupp is a German multinational conglomerate with a significant presence in the steel coil manufacturing industry. They have a diverse product range and focus on innovation and sustainability. 6. United States Steel Corporation: As a leading American steel producer, United States Steel Corporation plays a crucial role in the steel coil manufacturing industry. They have a strong presence in the automotive, construction, and energy sectors. 7. JFE Holdings, Inc.: JFE Holdings is a Japanese steel conglomerate and one of the key players in the steel coil manufacturing industry. They have a wide range of steel products and are known for their quality and customer-oriented approach. These are just a few of the key players in the steel coil manufacturing industry, and there are many other companies that contribute to this sector. The industry is highly competitive, and these companies continuously strive to innovate, improve efficiency, and meet the ever-evolving demands of the market.

- Q: What are the common methods of protecting steel coils from corrosion during storage?

- Common methods of protecting steel coils from corrosion during storage include applying a protective coating or film, using desiccants or moisture-absorbing materials, implementing proper ventilation and climate control, employing corrosion inhibitors or VCI (Vapor Corrosion Inhibitors), and ensuring adequate packaging and sealing to prevent exposure to moisture or contaminants.

- Q: How do steel coils contribute to the construction machinery industry?

- Steel coils are an essential component in the construction machinery industry. They play a crucial role in the manufacturing of heavy-duty machinery and equipment used in construction projects. One of the primary ways steel coils contribute to the construction machinery industry is through their use in the fabrication of structural components. These coils are often processed and shaped into beams, plates, and tubes, which form the framework of construction machinery. The strength and durability of steel make it an ideal material for these applications, as it can withstand heavy loads and harsh working conditions. Moreover, steel coils are also used in the production of various mechanical parts and components found in construction machinery. These include gears, shafts, axles, and hydraulic system components. The versatility of steel allows it to be easily machined and formed into complex shapes, enabling the creation of efficient and reliable machinery parts. In addition to its mechanical properties, steel coils also contribute to the construction machinery industry through their corrosion resistance. Construction machinery is often exposed to moisture, chemicals, and other environmental factors that can cause rust and deterioration. Steel coils with proper coatings or finishes can provide protection against corrosion, ensuring the longevity and performance of construction machinery. Furthermore, the availability and affordability of steel coils make them a preferred material for the construction machinery industry. Steel is widely produced and can be sourced from various suppliers, ensuring a steady supply chain. Its cost-effectiveness compared to other materials makes it an attractive option for manufacturers, allowing them to produce machinery at competitive prices. Overall, steel coils are vital to the construction machinery industry by providing strength, durability, corrosion resistance, and cost-effectiveness. Their use in the fabrication of structural components and mechanical parts ensures the reliability and efficiency of construction machinery, contributing to the growth and development of the industry.

- Q: How are steel coils used in the production of structural steel?

- Steel coils are used in the production of structural steel by being unwound and processed through various manufacturing techniques, such as rolling and shaping, to create different structural components like beams, columns, and plates.

Send your message to us

Hot Dip Galvanized Steel Plate in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords