Hot Dip Galvanized Steel Plank Catwalk 420*45*1.2*1829 CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 30000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

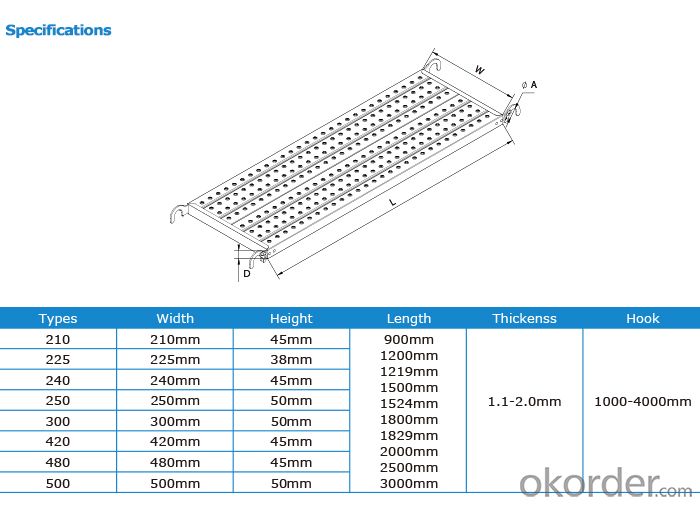

Hot Dip Galvanized Steel Plank Catwalk 420*45*1.2*1829 Description:

Material :Q235 (Carbon 235 Steel)

Size :420*45*1.2*1829 with hooks

Surface treatment :galvanized

Color :silver

Hot Dip Galvanized Steel Plank Catwalk 420*45*1.2*1829 Futures:

Hot dip galvanized steel plank is an ideal Economical & Eco-friendly scaffolding solution for Scaffolding system and Formwork system. A perfect choice for safety & low-cost & high-efficiency construction projects.

Even load capacity: >7kN/ m2

Max span < 2m & Recommended span between 1.2-1.5m.

Side box design with better anti - deforming capability

3 strengthen support designs with much stronger support force

500mm support spacing with better anti - deforming capability

hot dip galvanizing surface & lifespan > 5 years

Punching design to anti-skid & lighten weight

Stiffener design with reinforced the load bearing capacity

FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2. What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q: Said chrysanthemum disc scaffolding system, disc scaffolding system, wheel type scaffolding system, buckle scaffold, layher frame

- Crossbar HG-30 3001.67HG-60 6002.82HG-90 9003.97HG-120 12005.12HG-150 15006.28

- Q: The bottom of the cantilever scaffold must be provided with the sweeping rod

- Steel pipe: (1) steel pipe with 48mm outside diameter, wall thickness of 3.5mm steel welded pipe No. 3

- Q: First of all, is it painful? Obviously it will be painful I know, but is it severe?Also, what cleaning solutions/products do I need to minimise the risk of infections?And what type of bar should I get? I've heard that Bioplast and PTFE allow for better flexibility and therefore quicker healing, but wouldn't a flexible bar lead to mis-alignment on the two pierced holes? If this is so, what types of steel are safe for initial piercings?Thanks c:

- Ask how long they have been piercing and what certifications (if any) they carry, additionally verify close by regulations to ascertain if any are required. additionally ask how generally they spore verify their autoclave and while it grew to become into accomplished final time. Ask to ascertain a portfolio of HEALED piercings, exceptionally pictures of in spite of piercing you try to get.

- Q: Im in college football, I would be puting on and taking off my helmet, I usually keep it on though during practice...but would it be wise for me to get an industrial piercing a couple months before 2 a days and the football season...would the sweat maybe infect my ear, but I am a very clean guy? thanks, if you have an answer it will help my decision.....

- trust me, bro. bad idea. industrials are very tempermental at best. your helmet will cause every problem possible. any descent piercer would tell you the same. don't do it. they take up to a year to heal soif you really want one, quit football or wait til you're out of school.

- Q: Cells from an animal's muscles are processed with chemicals and they grow. The cells are transferred to a metal scaffold and are stimulated physically. In a few months, you have a big block of meat which can be ground and cooked. What do you have to add? Does this innovation mean the price of meat will become a very minor expense?

- Depends on how much it costs to stimulate the growth.

- Q: At 16 I took my bros 16 gauge piercing needle and pierced my left cartilage and it didn't hurt at all.... and I have a tattoo as well and I laughed through it. So pain isn't huge when it's a small amount.

- Gosh Industrial do hurt I'm not going to lie. Cartilage piercings don't hurt. But industrials are really hard to take care of. If you can handle pain then get it. They're worth it but they do hurt.

- Q: This is an answer to irreducible complexity. Are there any examples that we see in animals or organs? or on the cellular level? Are vestigial organs a form of quot;scaffoldingquot; that are in the process of being removed?

- The classic demonstration was in the E. coli long term experiment. A strain gained the ability to metabolize citric acid after 31,500 generations. Culturing preserved strains from 15,000 and 20,000 generations showed that there was an event that occurred in between that enabled the later conversion to citrate metabolism.

- Q: ..or anytime around whenThe Scarlet Letter was written.I am doing a paper on why the three scenes at the scaffold were so significant.So I decided to include the history of scaffolds, but I can't seem to find any information on them.help please? :]SOURCES..if possible! :]

- Execution by hanging.

- Q: How does the second scaffold scene morally change Hester Prynne?

- It is less about Hester because she has accepted her punishment. It is more about Dimmesdale.

- Q: Compared to Pankou scaffolding and scaffolding have what distinction, what are the advantages

- 3, Pankou scaffolding load intensity up to 200KN capacity4, Pankou scaffolding scaffolding activities. Abandon the traditional parts easily lost, easily damaged, and compared with the ordinary bowl-scaffold, saving up to 2/3 more than the amount of steel, so to a certain extent, greatly shorten the construction unit cost and economic loss.

Send your message to us

Hot Dip Galvanized Steel Plank Catwalk 420*45*1.2*1829 CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 30000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords